Understanding PI Controllers

1. The Allure of PI Control

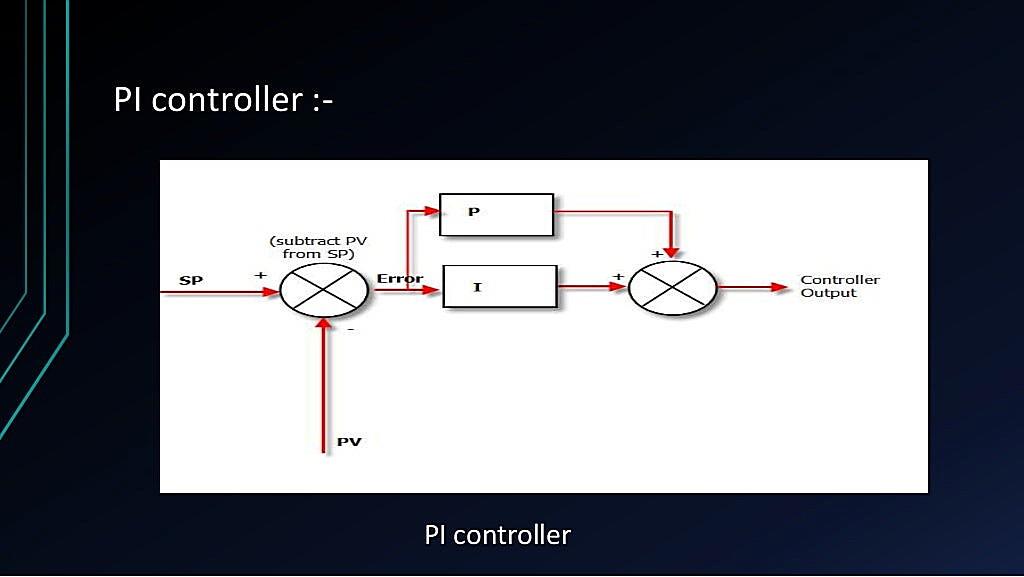

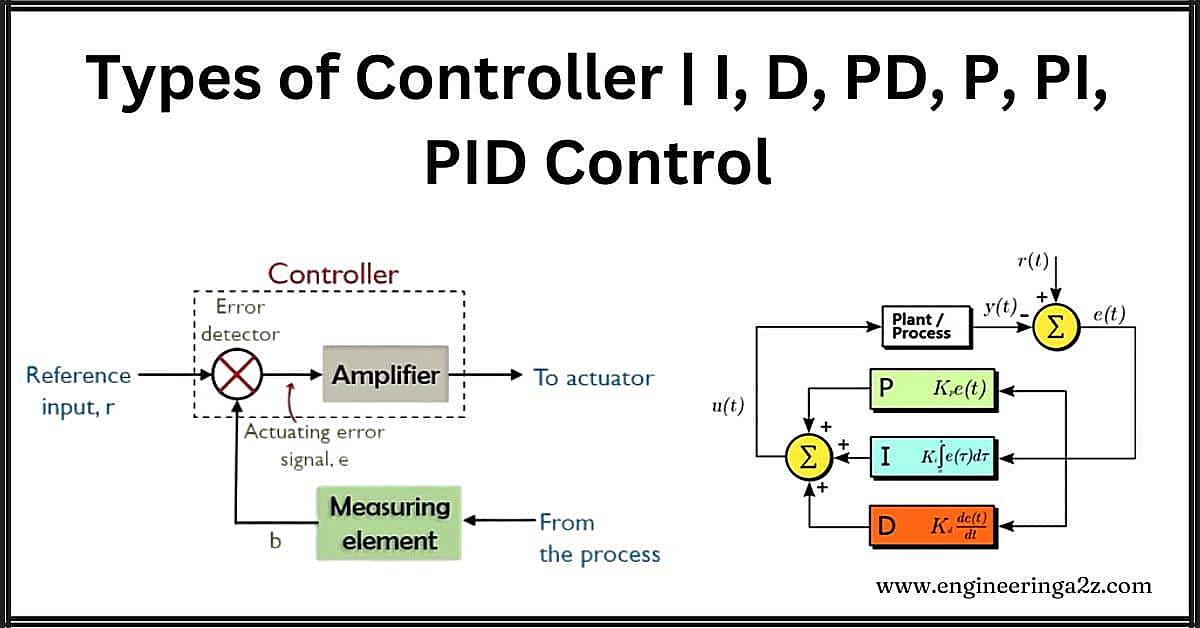

PI controllers, short for Proportional-Integral controllers, are like the seasoned veterans of the control systems world. They’re widely used in industrial automation, robotics, and even everyday appliances like your thermostat. The reason for their popularity? They aim to drive a system to a desired setpoint, minimizing errors and keeping things stable. Theyre particularly good at eliminating steady-state errors, which is a fancy way of saying they can get rid of that persistent little difference between where you want the system to be and where it actually is.

Imagine you’re trying to keep the temperature in your house at a comfortable 72 degrees Fahrenheit. A simple on-off switch might get you close, but it will constantly overshoot and undershoot, leaving you shivering or sweating. A PI controller, on the other hand, would gradually adjust the heating or cooling output to smoothly reach and maintain that perfect 72-degree mark. That’s the magic of combining proportional and integral action.

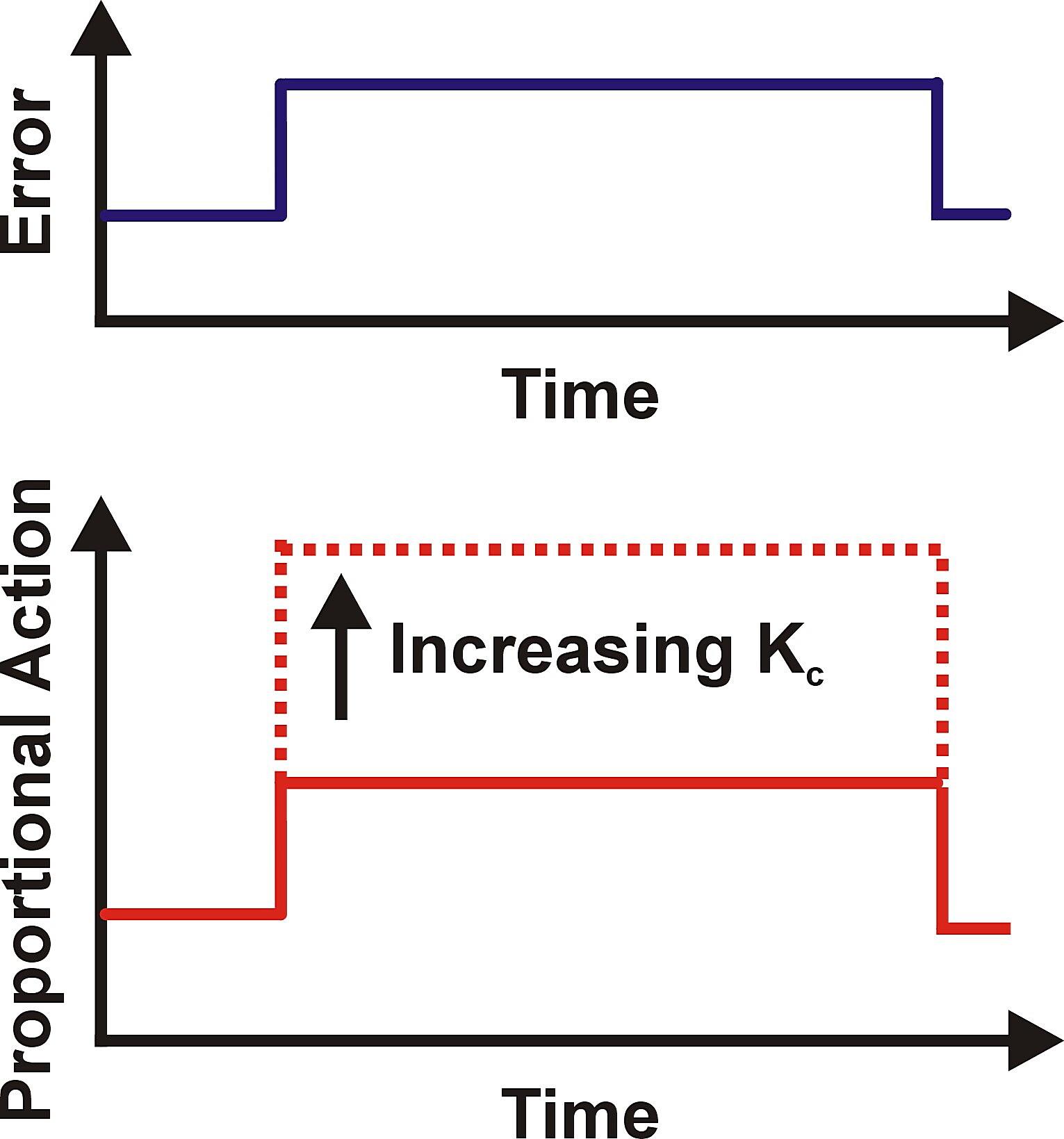

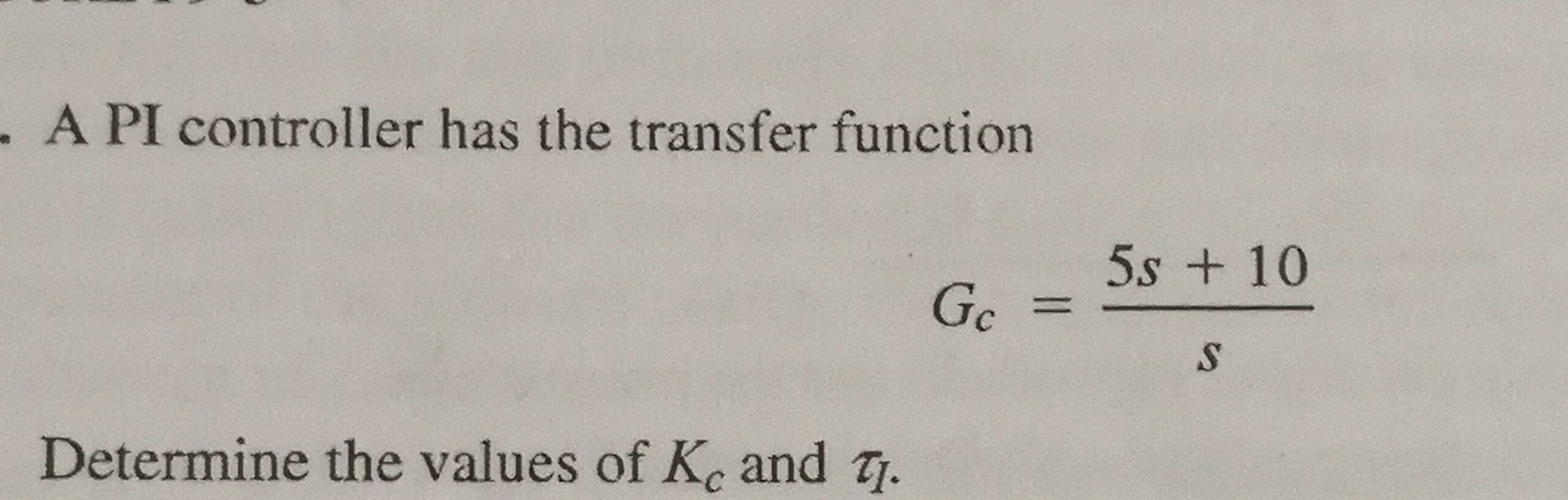

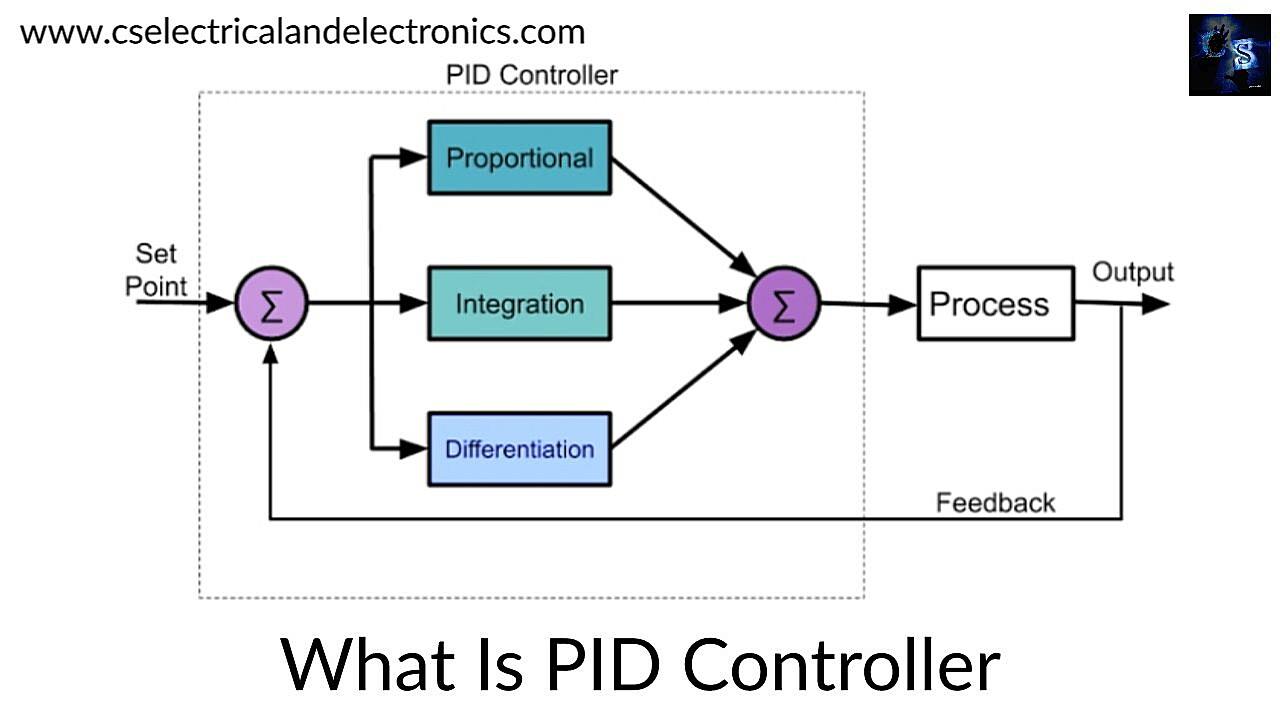

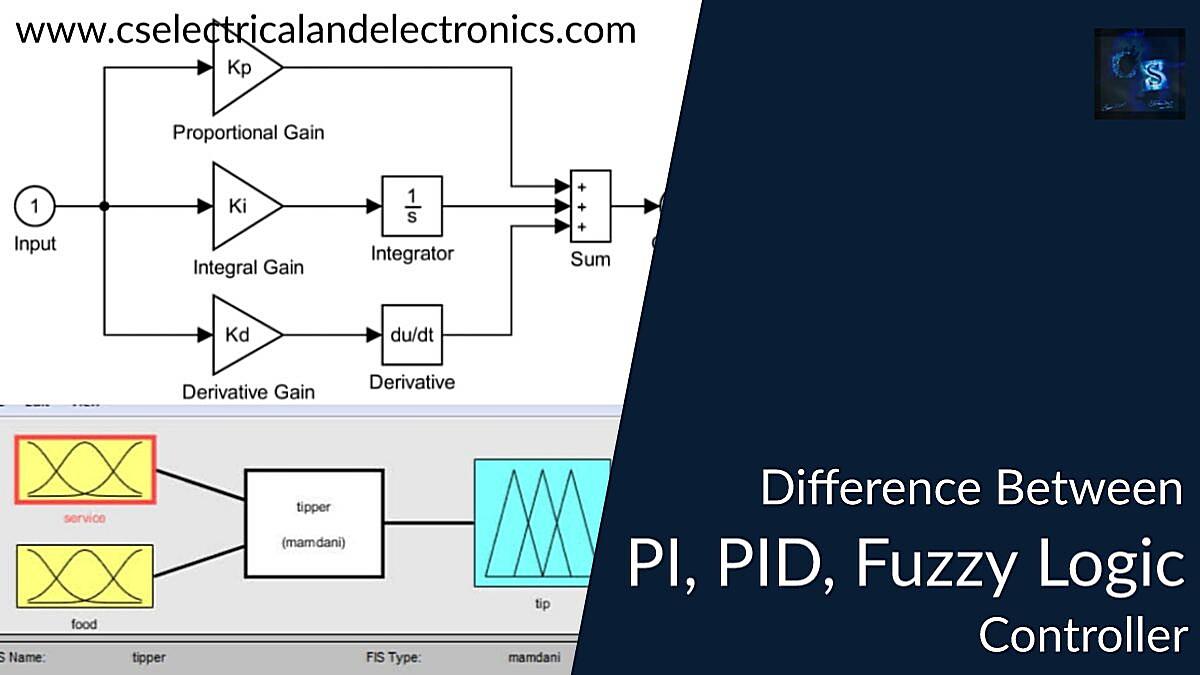

The proportional part responds instantly to the current error; the bigger the error, the stronger the response. Think of it as the immediate, corrective action. The integral part, however, looks at the history of the error. Even a small, persistent error will accumulate over time, eventually leading the integral term to take action. This is what eliminates that steady-state error, ensuring the system eventually settles exactly where you want it.

So, with all this talk about stability and error elimination, are PI controllers the perfect solution for everything? Well, not quite. Like any good thing, they come with their own set of challenges.

The Downside

2. The Challenge of Tuning

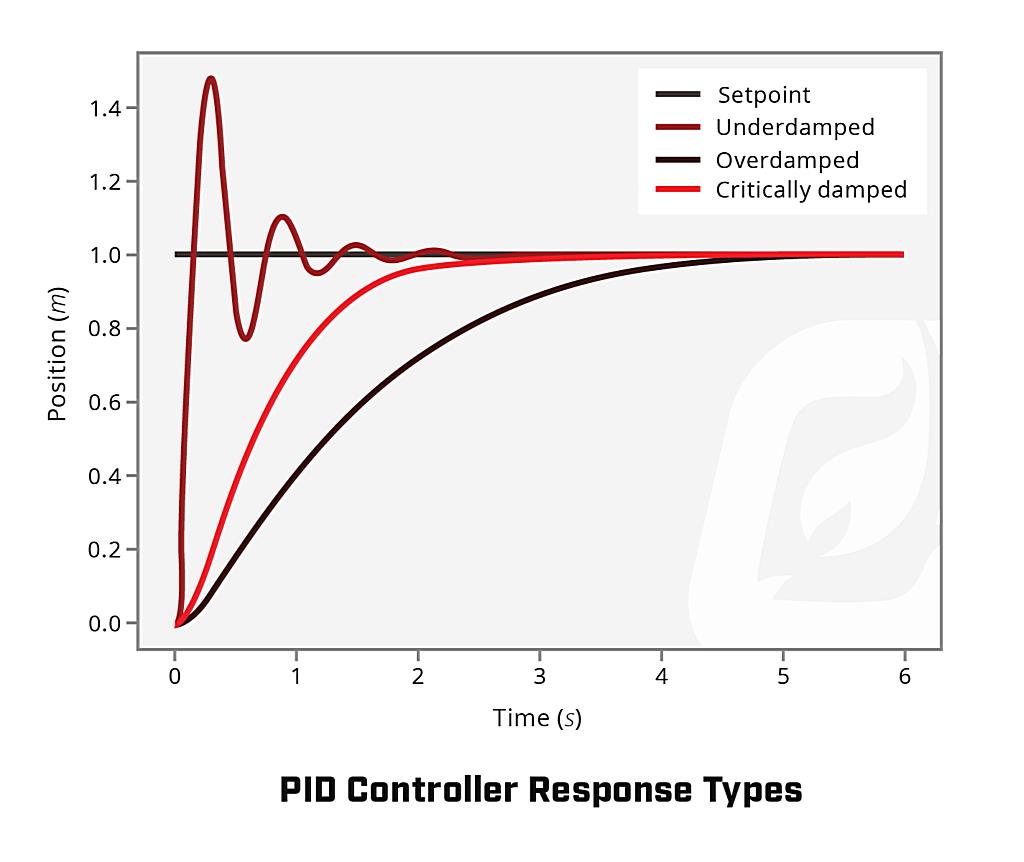

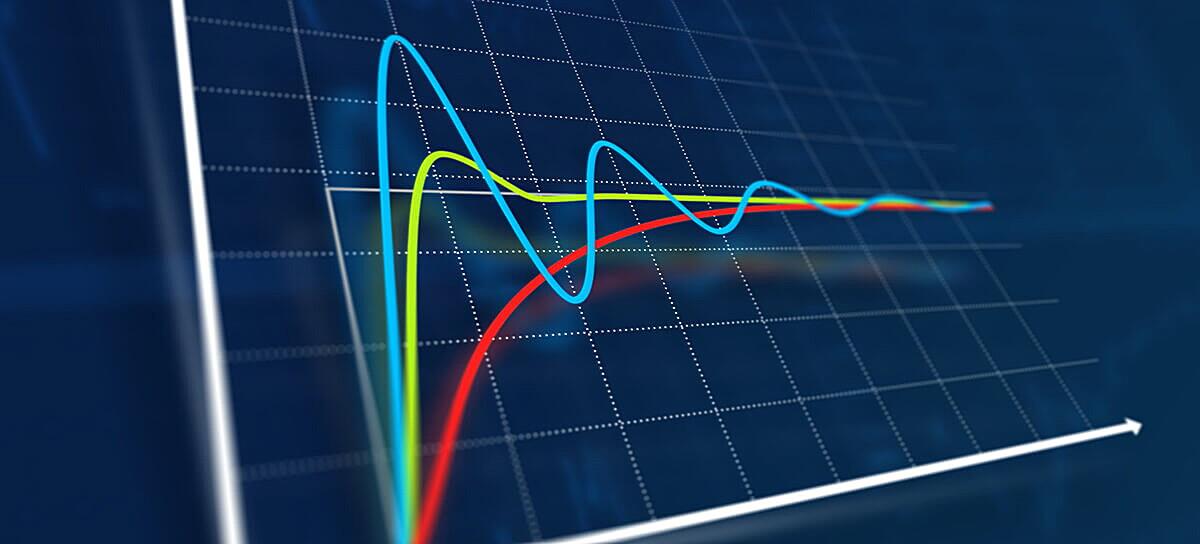

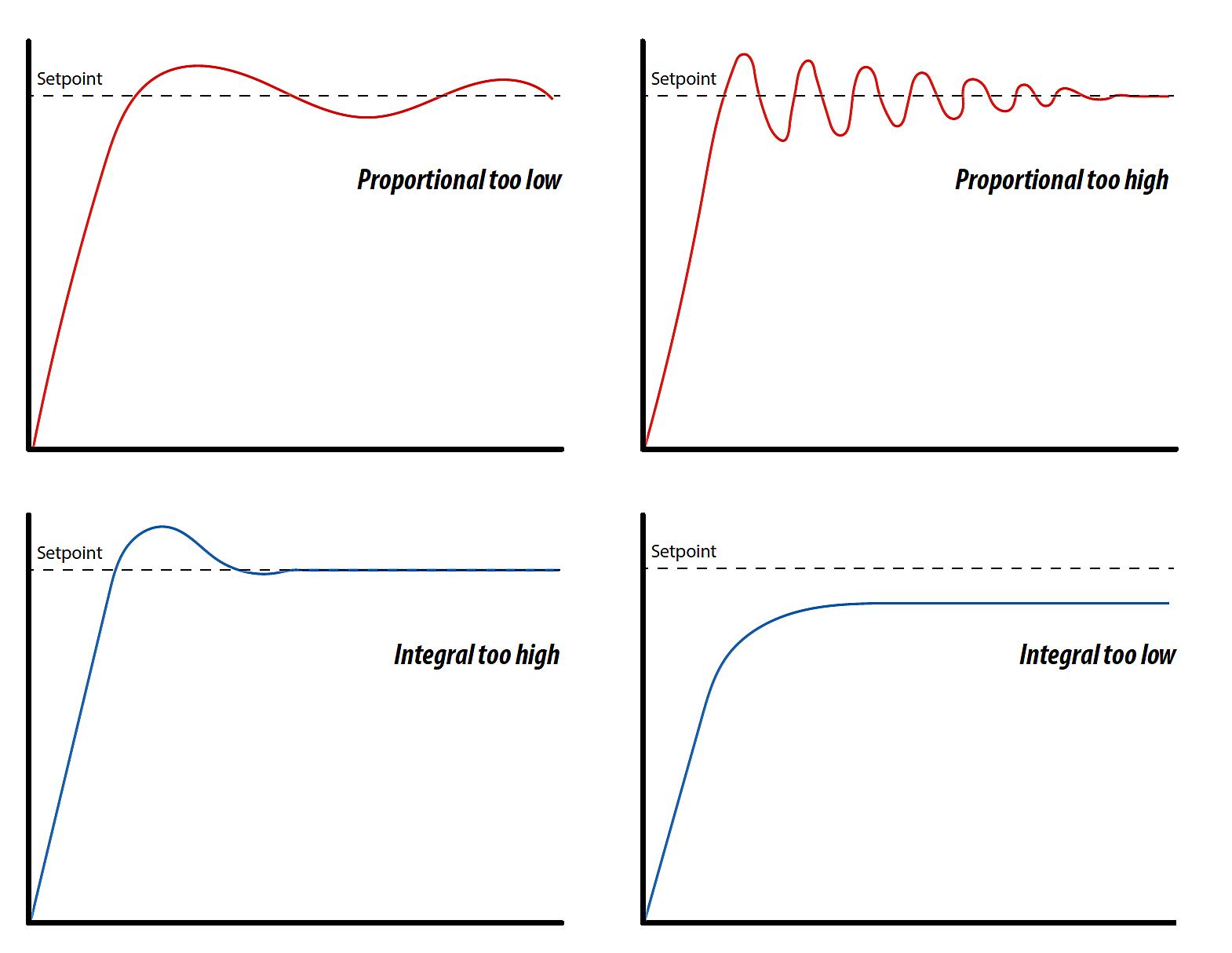

One of the primary drawbacks of PI controllers lies in the tuning process. Finding the right balance between the proportional and integral gains can be tricky. If the gains are too low, the system will be sluggish and slow to respond. If they’re too high, the system can become unstable, oscillating wildly around the setpoint. It’s a bit like trying to adjust the shower temperature; too much hot, then too much cold, until you finally find that sweet spot.

Tuning often involves a combination of theoretical calculations, simulations, and good old-fashioned trial and error. There are various methods, like Ziegler-Nichols tuning, but they often provide a starting point rather than a definitive solution. The “best” values for the gains depend heavily on the specific characteristics of the system being controlled. A system with fast dynamics will require different tuning than one with slow dynamics.

Adding to the complexity, the optimal tuning parameters can change over time as the system’s characteristics drift due to wear and tear, environmental changes, or alterations to the process. This means the controller might need to be periodically retuned to maintain optimal performance, which can be a time-consuming and sometimes frustrating process.

Imagine trying to bake a cake with a finicky oven. Sometimes it bakes perfectly, other times it’s burnt on the outside and raw in the middle. A PI controller with poor tuning is like that oven — unpredictable and unreliable.

The Impact of Integral Windup

3. What is Integral Windup Anyway?

Another significant disadvantage of PI controllers is integral windup. This occurs when the control signal saturates, meaning it reaches its maximum or minimum limit. This often happens when the system is faced with a large disturbance or a significant change in the setpoint.

When the control signal saturates, the integral term keeps accumulating, even though the controller can’t actually do anything more to influence the system. This means that when the disturbance is finally removed or the setpoint is reached, the integral term has built up a large value, causing the controller to overshoot the desired value significantly. Its like revving your engine to the redline while stuck in the mud; when you finally get traction, youll shoot forward much faster than you intended.

Integral windup can lead to instability, oscillations, and poor performance. It’s particularly problematic in systems with limited actuation capabilities, such as those with valves that can only open or close so far. The accumulated integral action essentially “winds up” the controller, leading to a delayed and exaggerated response.

There are several techniques to mitigate integral windup, such as anti-windup schemes that prevent the integral term from accumulating when the control signal is saturated. However, implementing these schemes adds complexity to the controller design.

Sensitivity to Noise and Disturbances

4. The Ripple Effect

PI controllers, especially the integral term, can be sensitive to noise and disturbances in the system. High-frequency noise can be amplified by the integral term, leading to unwanted oscillations and instability. Similarly, sudden disturbances can cause the integral term to react aggressively, potentially leading to overshoots and settling time issues.

Imagine you’re trying to balance a broom on your hand. Small, random movements are easy to compensate for. But if someone bumps your arm, you’ll likely overcorrect and the broom will fall. A PI controller reacting to noise is similar — small, insignificant fluctuations get amplified and cause unnecessary adjustments.

Filtering can be used to reduce the impact of noise, but it can also introduce delays into the system, potentially affecting its stability and responsiveness. Its a balancing act; you want to filter out the noise without making the controller sluggish.

Dealing with disturbances often requires a more sophisticated control strategy, such as feedforward control or disturbance rejection techniques, which can add complexity to the system design.

Performance Limitations with Complex Systems

5. The Limits of Simplicity

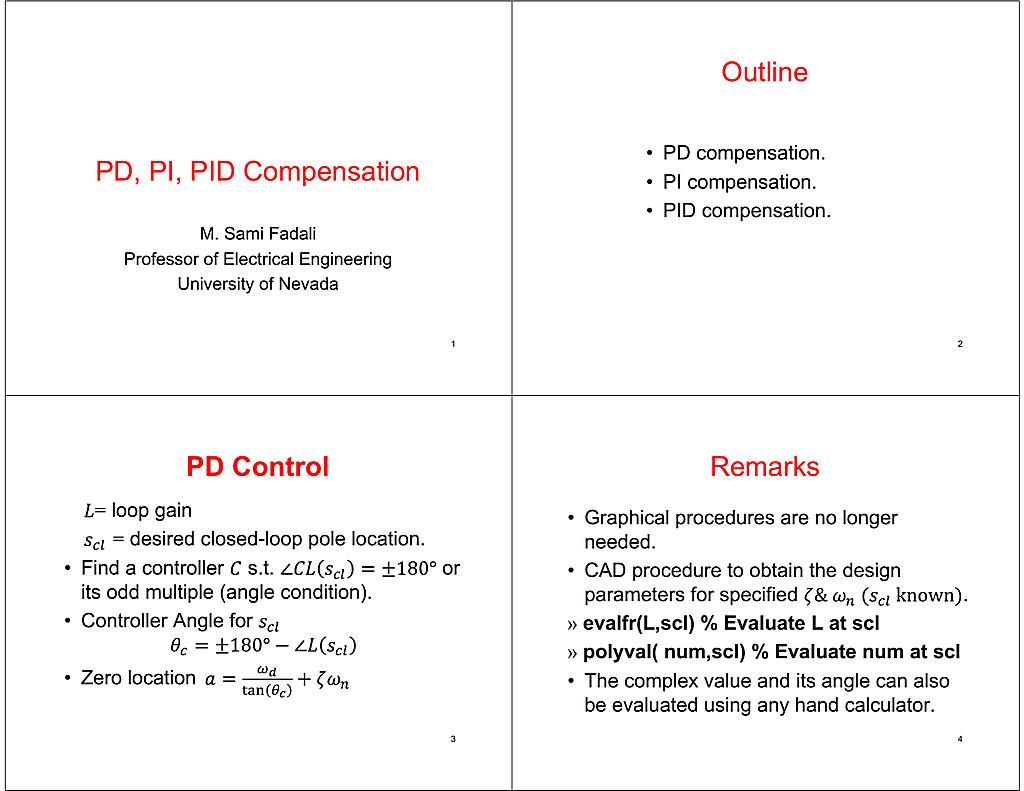

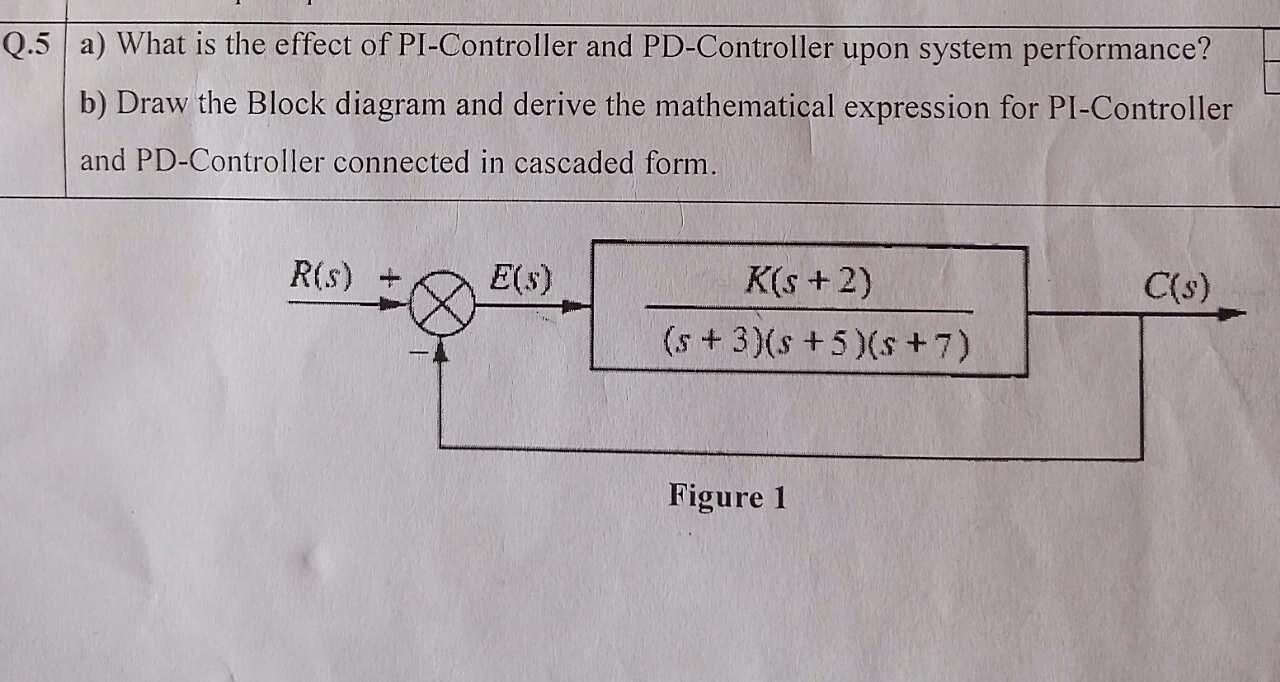

While PI controllers are effective for many simple systems, they can struggle with more complex systems that exhibit nonlinear behavior, time delays, or multiple inputs and outputs. The inherent simplicity of the PI control structure limits its ability to effectively handle these complexities.

Nonlinearities, such as saturation or hysteresis, can cause the controller to behave unpredictably. Time delays, which are common in many industrial processes, can make it difficult for the controller to accurately predict the system’s response. And systems with multiple inputs and outputs often require more sophisticated control strategies, such as Model Predictive Control (MPC) or multivariable control, to achieve optimal performance.

Think of it like trying to conduct an orchestra with only a baton. You can keep the rhythm, but you can’t possibly control the individual instruments and create a complex, nuanced musical piece. PI controllers are like that baton — effective for simple tasks, but inadequate for complex orchestrations.

In these cases, more advanced control techniques are often required to achieve the desired level of performance. However, these techniques come with their own set of challenges, such as increased complexity, computational requirements, and the need for accurate system models.

FAQ

6. Q

A: PI controllers aren’t always the best choice. If your system is highly nonlinear, has significant time delays, or requires precise control over multiple variables simultaneously, you might want to consider more advanced control strategies. Also, if you’re dealing with a system where quick response time is critical and overshoot is unacceptable, a PID controller (with a derivative term) might be a better fit.

7. Q

A: One of the most common errors is not understanding the system dynamics properly. Blindly applying tuning rules without considering the specific characteristics of the process can lead to poor performance and instability. It’s crucial to have a good understanding of how the system responds to changes in the control signal.

8. Q

A: While not necessarily “easier,” some adaptive control techniques can automatically adjust the controller parameters to compensate for changes in the system. These techniques often require more computational power and a good understanding of the system, but they can be a good option for systems where manual tuning is difficult or impractical.