Understanding Motion Control

1. What’s the Big Deal with Motion Control?

Ever watched a robot smoothly weld a car part or a CNC machine precisely carve a design? That’s motion control at work! It’s all about getting machines to move exactly as we want them to. But there’s more than one way to skin a cat, or in this case, control a machine’s movement. Two popular methods are point-to-point and continuous path control. Let’s break down the differences.

Imagine drawing a picture. You could either carefully place a dot in one spot, then another, and so on (point-to-point). Or you could smoothly draw a line without stopping (continuous path). Motion control is similar! Each method is best suited for different jobs.

Think of it like choosing between a bicycle and a car. A bicycle is great for short, precise trips around the neighborhood (point-to-point). A car is better for long, flowing drives on the highway (continuous path). Both get you places, but they excel in different scenarios.

So, grab your metaphorical hard hat — let’s dive into the details and see which control system reigns supreme (or at least, is best for your particular application!). It’s not about which one wins, but which one fits the task at hand.

Point-to-Point (PTP) Control

2. Hop, Skip, and Jump

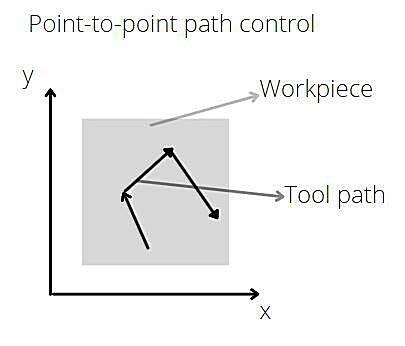

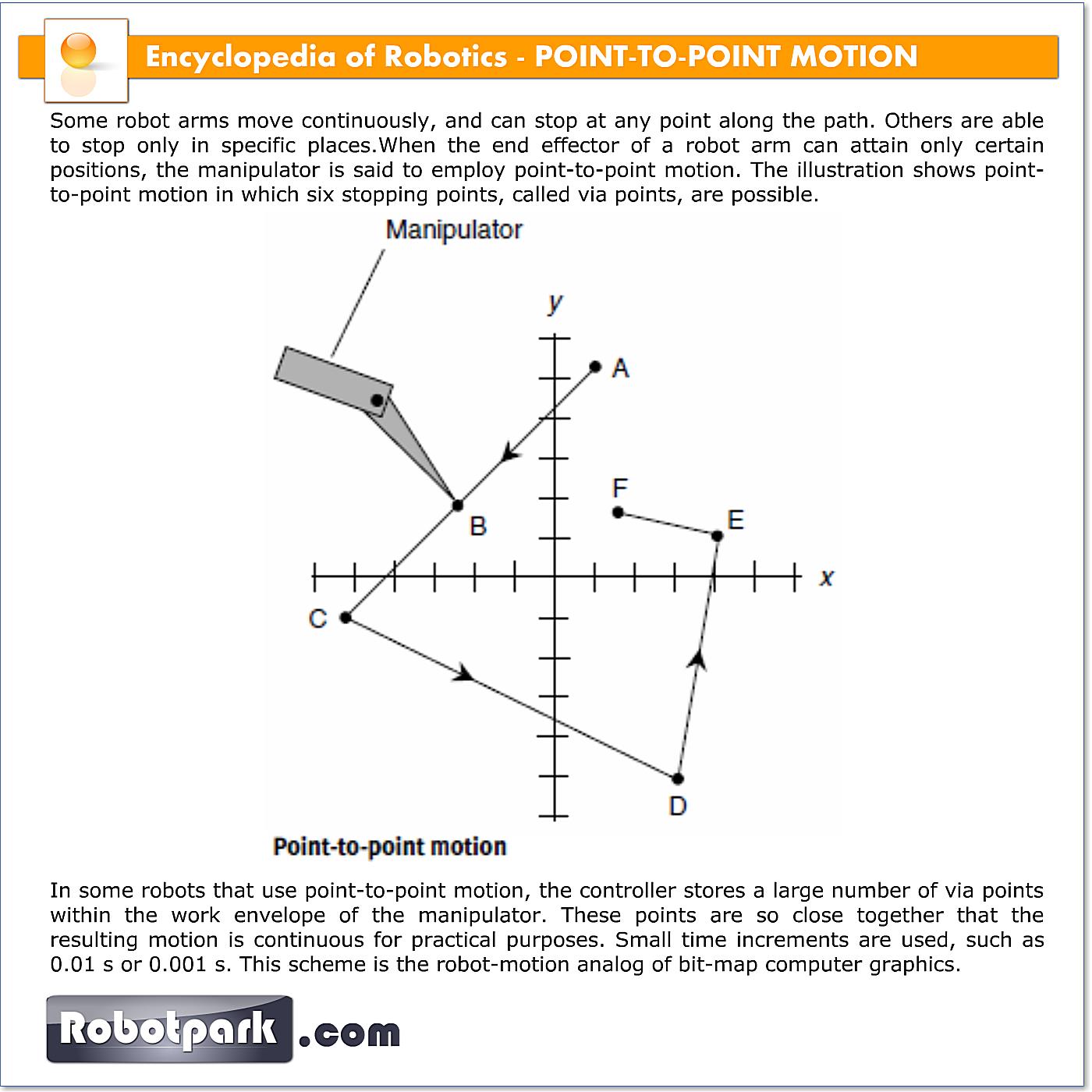

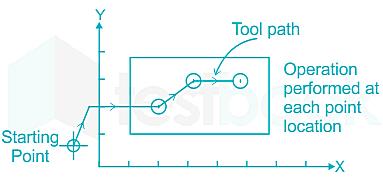

Point-to-point (PTP) control is all about getting from one specific location to another. The path taken in between those points doesn’t really matter. The focus is solely on achieving the target position accurately and quickly.

Think of an elevator. You press the button for the 10th floor, and the elevator gets you there as efficiently as possible. Does it care about the exact route it takes between floors? Nope! It just wants to get you to your destination. That’s PTP in a nutshell.

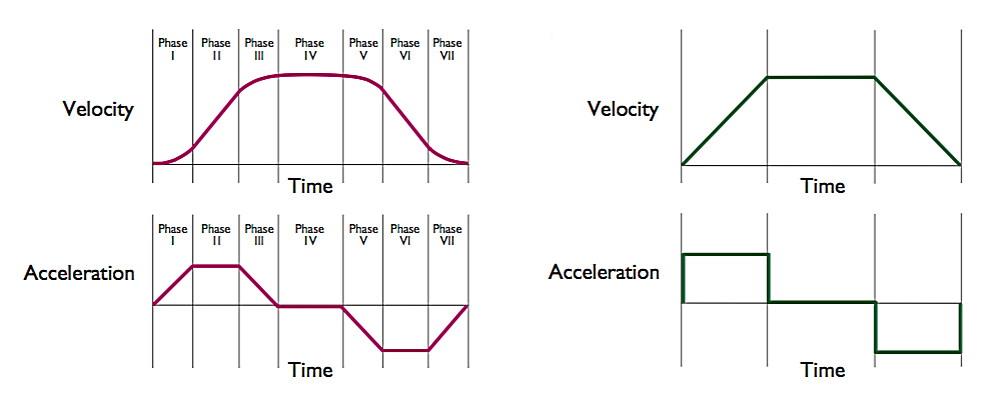

These systems often prioritize speed. The machine will accelerate to its maximum velocity, travel towards the target, and then decelerate to a stop at the final point. The actual trajectory during the move might be a straight line, or a curved path, but its not precisely controlled.

Common applications include drilling, pick-and-place robots, and inserting components. Basically, any task where the intermediate path is unimportant, and only the final position matters, is a good candidate for PTP control. It’s like sending a package — as long as it arrives, who cares if the delivery truck took a scenic route?

Continuous Path (CP) Control

3. The Beauty of the Flow

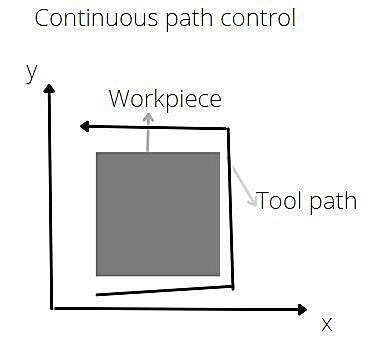

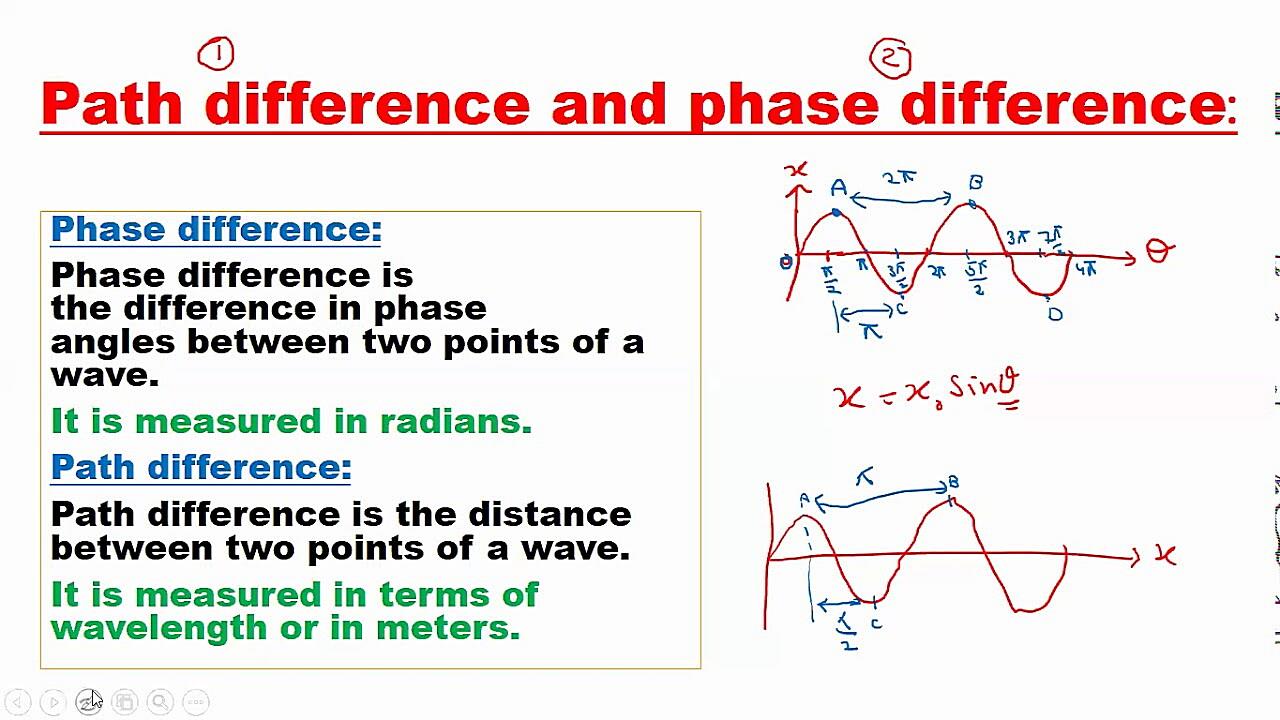

Continuous path (CP) control, on the other hand, is obsessed with the entire path taken. It’s not enough to simply reach the destination; the machine must follow a precisely defined trajectory from start to finish.

Imagine a painter using a brush to create a flowing line on a canvas. The painter doesn’t just care about the start and end points of the line; they care about every curve, every nuance, along the way. That’s CP control in action.

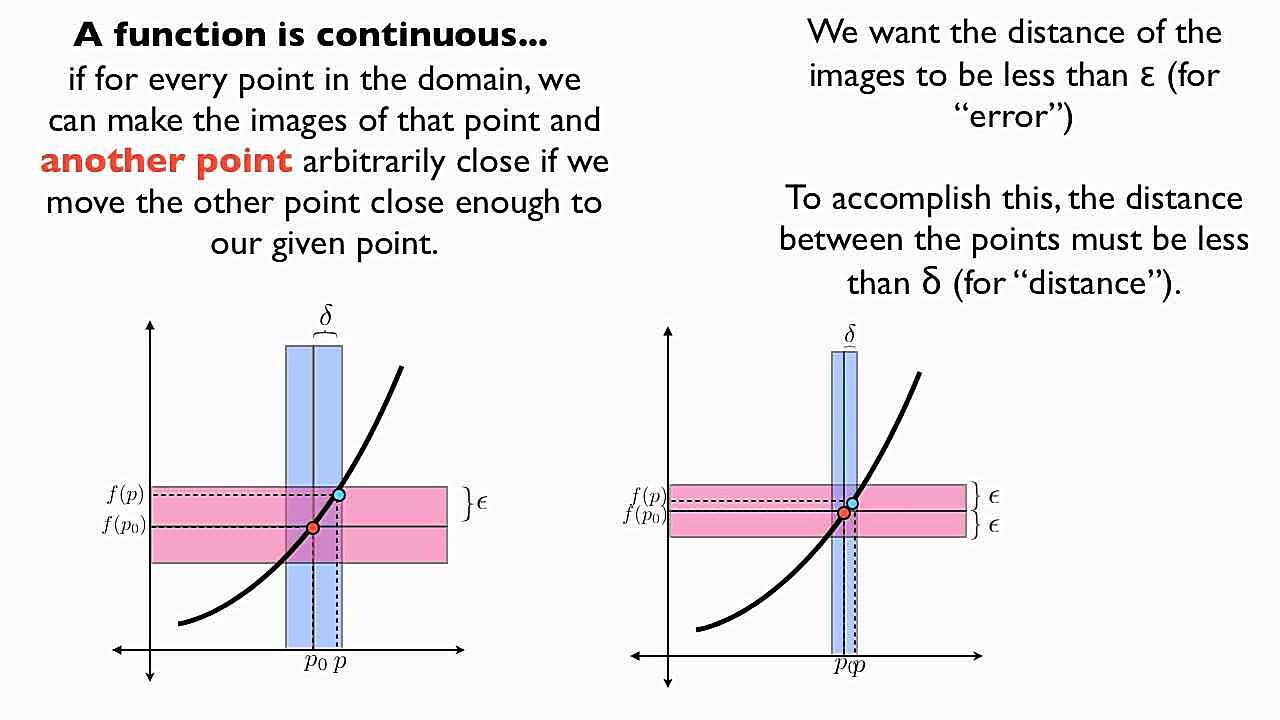

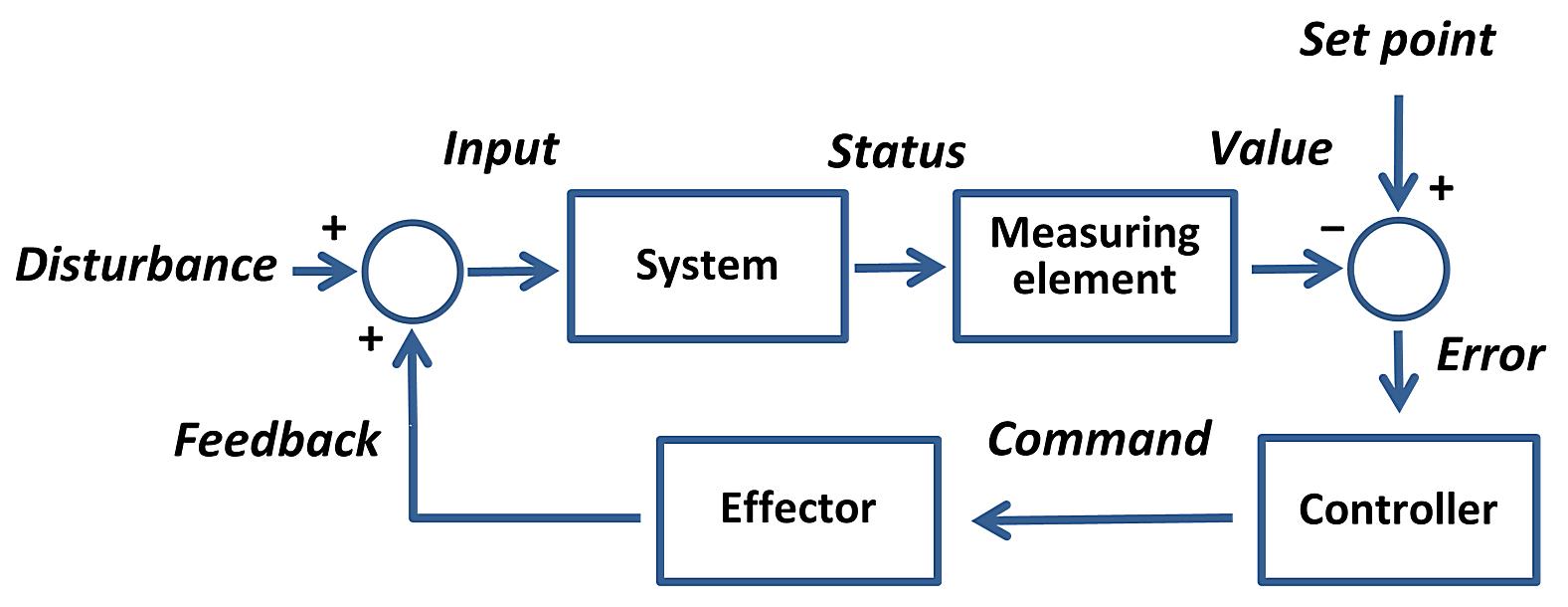

CP control systems require precise coordination of multiple axes of motion. The controller constantly monitors the actual path and makes adjustments to ensure that it closely matches the programmed path. This demands significantly more computational power and sophisticated algorithms compared to PTP.

Examples abound in CNC machining (cutting intricate shapes), robotic welding (laying down a perfect bead), and laser cutting (following a complex contour). Anywhere where the shape and form of the path are crucial, CP control is the go-to solution. It’s like a figure skater — the judges aren’t just impressed by where they end up, but how they got there!

Key Differences Summarized

4. PTP vs. CP

Let’s put it all together in a handy comparison:

Focus: PTP focuses on reaching the final destination quickly and accurately. CP focuses on following a specific path accurately.

Path Control: PTP doesn’t precisely control the path between points. CP meticulously controls the entire path.

Complexity: PTP is generally simpler and less computationally intensive. CP is more complex and requires more processing power.

Applications: PTP is suited for tasks like drilling and pick-and-place. CP is ideal for CNC machining, robotic welding, and laser cutting.

Analogy: PTP is like driving to a specific address without caring about the route. CP is like following a GPS route turn-by-turn.

Choosing the Right Control System

5. Which One Should You Pick?

The best control system depends entirely on the specific application. Ask yourself these questions:

Is the path important? If the shape of the path matters, choose CP. If only the final position matters, PTP might suffice.

What’s the required accuracy? CP generally offers higher accuracy in terms of path following. PTP is accurate in reaching the final destination.

What’s the budget? PTP systems tend to be less expensive than CP systems due to their lower complexity.

What’s the cycle time? PTP can often achieve faster cycle times for simple movements. CP may be slower due to the need for precise path control.

Consider these factors carefully, and you’ll be well on your way to selecting the perfect motion control system for your needs. It’s about finding the right tool for the job, ensuring efficiency and accuracy in your automated processes. After all, nobody wants a robot that trips over its own feet while trying to do something simple!

Real-World Examples

6. Where Do We See These Systems Used?

Let’s explore a few more concrete examples to solidify the concepts:

Automated Assembly: A robot placing screws into pre-drilled holes in a product uses PTP control. The robot just needs to accurately position the screwdriver above each hole. The path it takes doesn’t matter.

3D Printing: A 3D printer nozzle laying down layers of plastic follows a continuous path. The printer must precisely control the nozzle’s movement to create the desired shape.

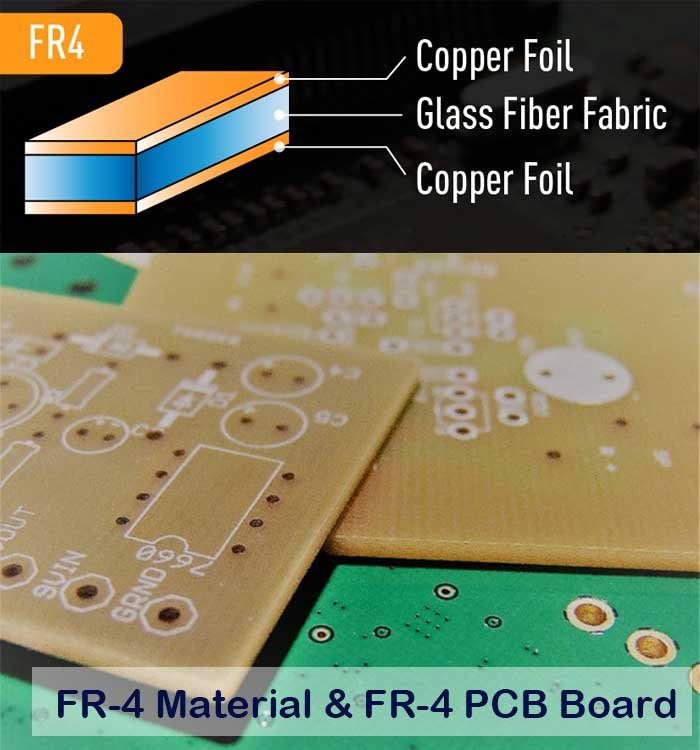

PCB Drilling: Drilling holes on a printed circuit board (PCB) is often done with PTP control. The drilling head moves quickly from hole to hole, focusing on the accuracy of each hole’s location.

Waterjet Cutting: Cutting complex shapes out of materials using a waterjet requires CP control. The waterjet needs to follow a precise path to create the desired design.

By visualizing these examples, it becomes easier to appreciate the versatility and distinct advantages of both point-to-point and continuous path control systems. Choosing the right approach can significantly impact the efficiency, accuracy, and overall quality of the final product.

Frequently Asked Questions (FAQs)

7. Your Questions Answered!

Here are a few common questions about point-to-point and continuous path control:

Q: Can a system use both PTP and CP control?

A: Absolutely! Many advanced control systems can switch between PTP and CP modes depending on the specific task requirements. This provides maximum flexibility.

Q: Is one system inherently better than the other?

A: Nope! Each system has its strengths and weaknesses. The best choice depends on the application. Think of it like choosing between a hammer and a screwdriver — both are useful tools, but they’re designed for different purposes.

Q: What are the programming differences between PTP and CP?

A: PTP programming typically involves specifying target coordinates. CP programming requires defining the entire path, often using complex mathematical equations or CAD/CAM software.

Q: Are there hybrid approaches that combine aspects of PTP and CP?

A: Yes, absolutely! Some systems employ techniques that blend elements of both PTP and CP. For instance, a system might use PTP to quickly move between general areas and then switch to CP for fine-tuning or contouring operations.