You May Also Like :

Unveiling FR4

1. What Exactly Is FR4? Let’s Break It Down

Ever wondered what that green (or sometimes other colors!) board inside your computer, phone, or pretty much any electronic device is made of? Chances are, it’s FR4. But what does FR4 actually mean? Well, it’s not some fancy code name from a sci-fi movie. It stands for “Flame Retardant 4.” A bit less exciting now, huh? But don’t let the name fool you; this material is essential.

Think of FR4 as the sturdy foundation upon which all the electronic components live. It’s the backbone, the motherboards mother, if you will. It provides structural support, insulation, and a place for all those tiny circuits to connect.

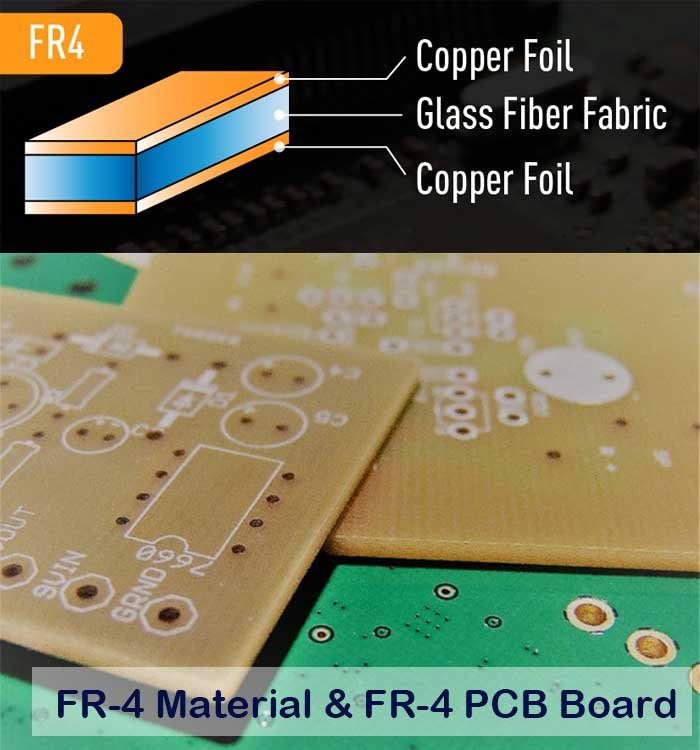

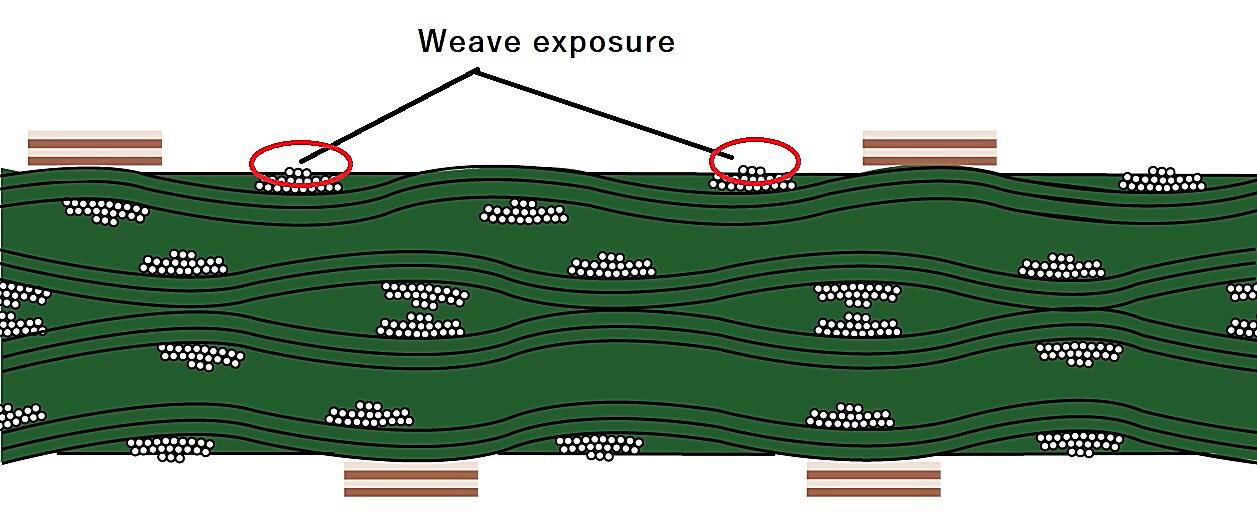

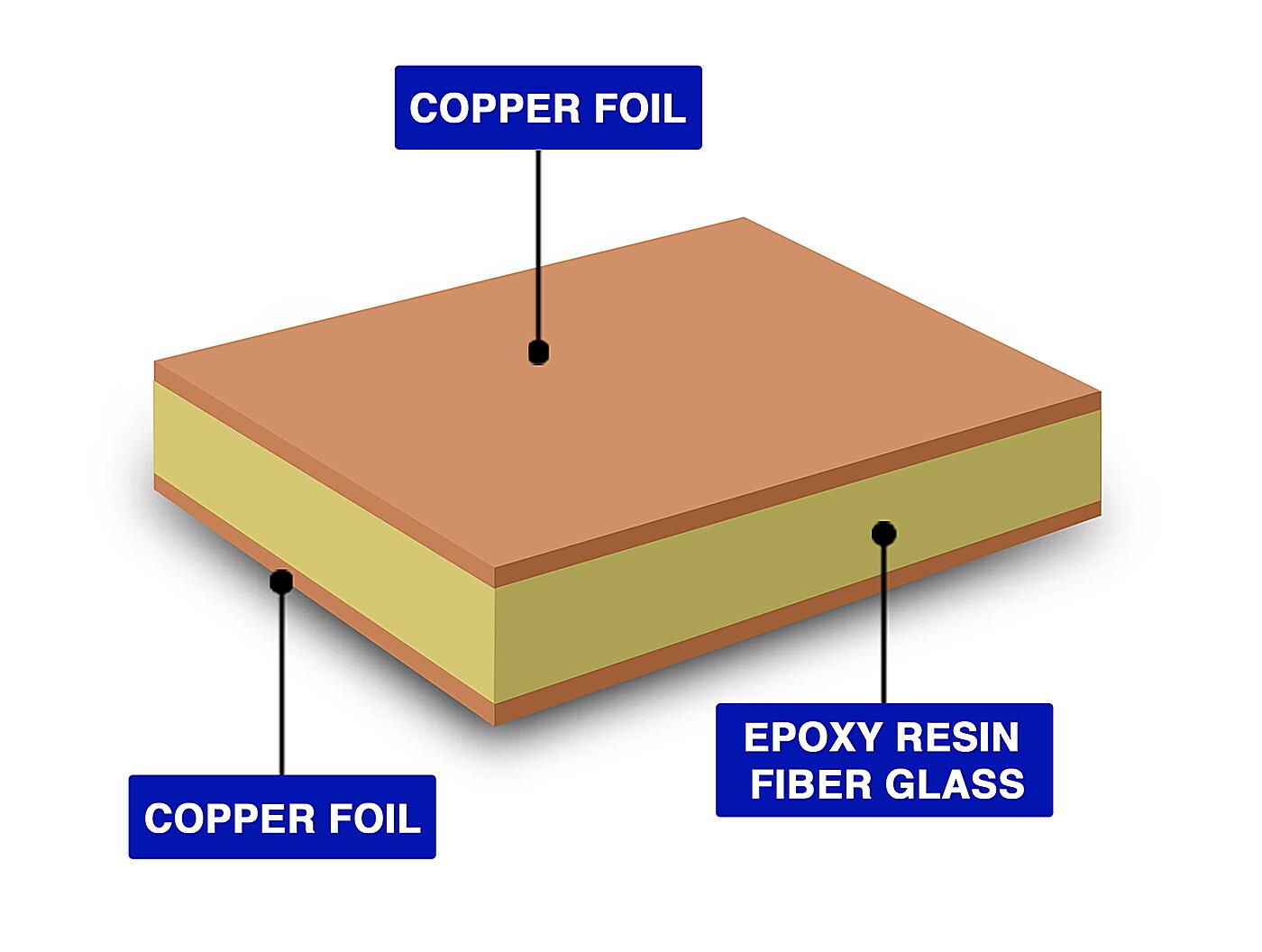

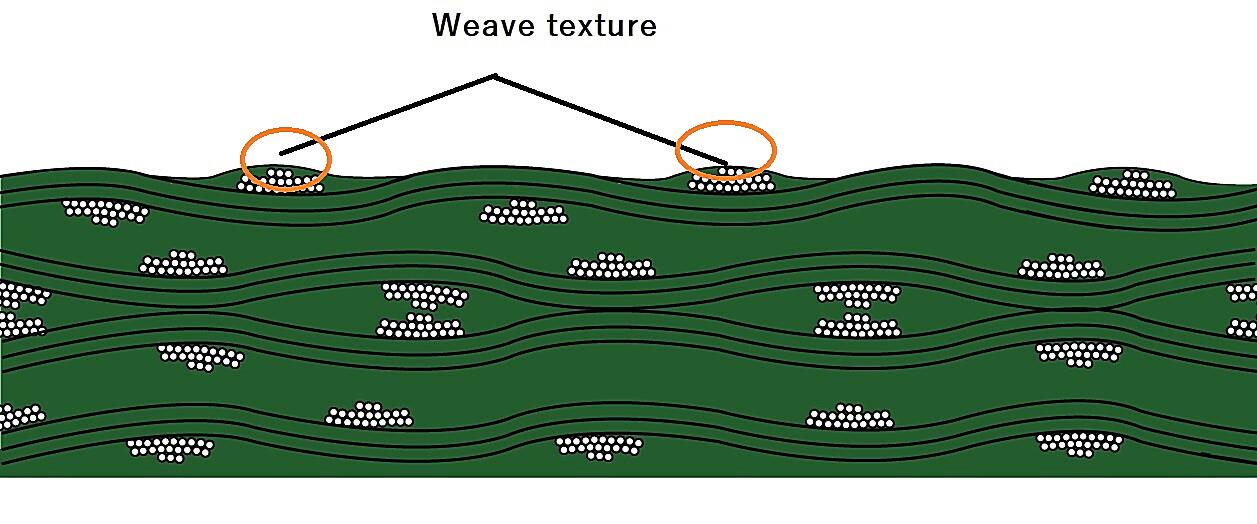

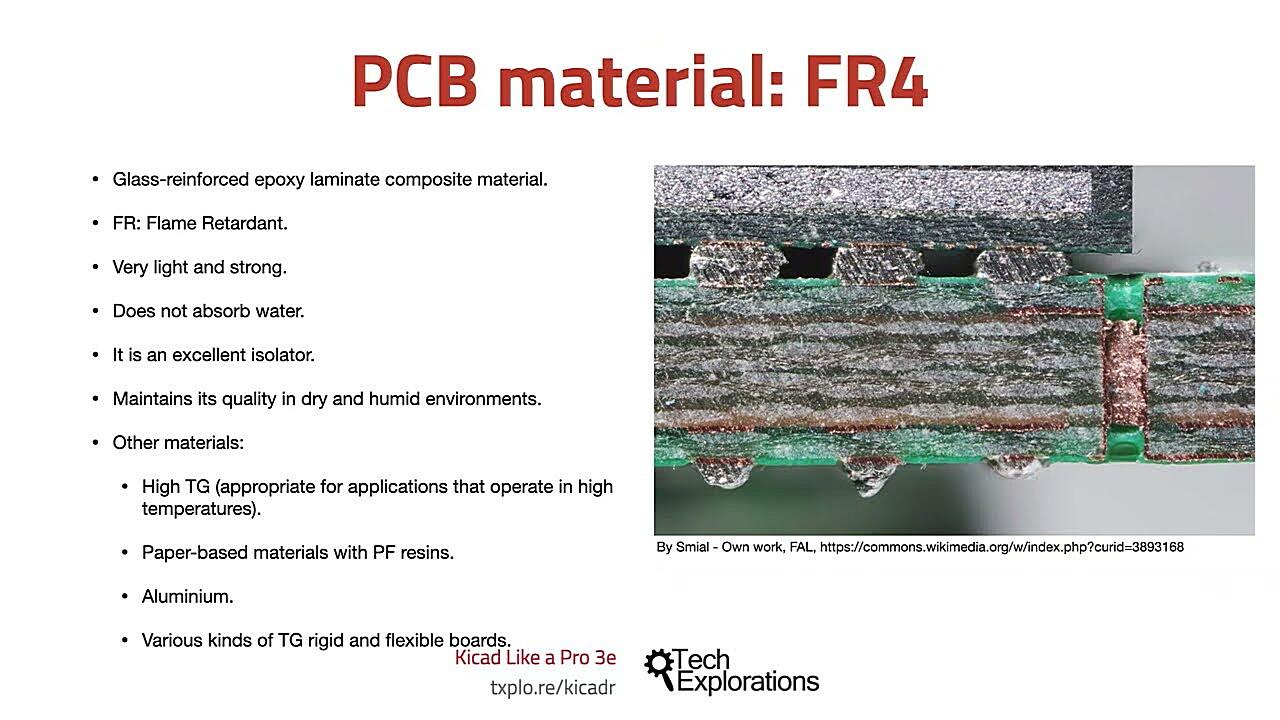

Specifically, FR4 is a composite material. That means it’s made up of multiple things working together. Usually, it consists of woven fiberglass cloth impregnated with a flame-retardant epoxy resin. The fiberglass provides strength and rigidity, while the epoxy binds it all together and gives it those insulating properties we need to keep our electronics from short-circuiting and going up in smoke (literally, since its flame retardant!).

Its the unsung hero, quietly doing its job, preventing electrical chaos. Without it, well, our digital world would be a much less reliable and far more flammable place. So next time you’re using your phone, take a moment to appreciate the humble FR4 inside.

The Key Characteristics of FR4

2. Digging Deeper

Okay, so we know FR4 is flame retardant and provides a stable platform for electronics. But what are some of its other qualities that make it so widely used?

First off, it’s got pretty good electrical insulation. This is crucial because we don’t want electricity jumping where it shouldn’t. FR4 prevents those unwanted electrical connections, ensuring everything flows correctly through the circuits.

Secondly, FR4 is relatively strong and rigid. It can withstand a good amount of stress and keeps components securely in place. Imagine trying to solder tiny components onto a flimsy, wobbly board. Not fun! FR4’s stability makes the manufacturing process much easier and the final product much more durable.

Thirdly, it’s relatively inexpensive compared to some other high-performance materials. This is a huge factor in mass-produced electronics. Using a super-expensive material for every circuit board would significantly drive up the cost of our gadgets.

Finally, FR4 is relatively easy to work with. It can be easily cut, drilled, and machined, making it suitable for a variety of board shapes and sizes. And it plays well with the various etching and soldering processes used in PCB (Printed Circuit Board) manufacturing. So, beyond just green circuit boards, expect to see FR4 material in various thickness, shapes and also colors. The color usually comes from the coating.

FR4 in Action

3. From Smartphones to Satellites

Where don’t you find FR4 might be a better question! Because of its versatility, affordability, and reliability, it’s used in a vast range of applications.

Think about your computer. The motherboard, graphics card, and pretty much every other circuit board inside are made of FR4. Then move on to your phone. Again, FR4 is the foundation of its internal circuitry. Your TV? FR4. Your car’s electronic control unit (ECU)? You guessed it — FR4.

But it’s not just consumer electronics. FR4 is also used in industrial equipment, medical devices, aerospace applications (yes, even satellites!), and military hardware. Basically, anywhere there’s electronics, there’s likely to be FR4 lurking beneath the surface.

The adaptability of FR4 makes it a cornerstone material in the electrical engineering industry. Its consistent performance across different applications means engineers can rely on it for structural integrity and electrical insulation, regardless of the product’s complexity or environment.

Beyond the Basics

4. Not All FR4 Is Created Equal

While “FR4” is a general term, there are actually different grades and variations with slightly different properties. For example, some FR4 materials have higher temperature resistance, while others are designed for higher-frequency applications.

The choice of FR4 depends on the specific requirements of the application. Factors like operating temperature, electrical performance, and mechanical stress all play a role in selecting the right material.

For example, high-speed digital circuits often require FR4 with a lower dielectric constant to minimize signal loss. On the other hand, power electronics operating at high temperatures might need FR4 with enhanced thermal properties. It’s all about choosing the right tool for the job.

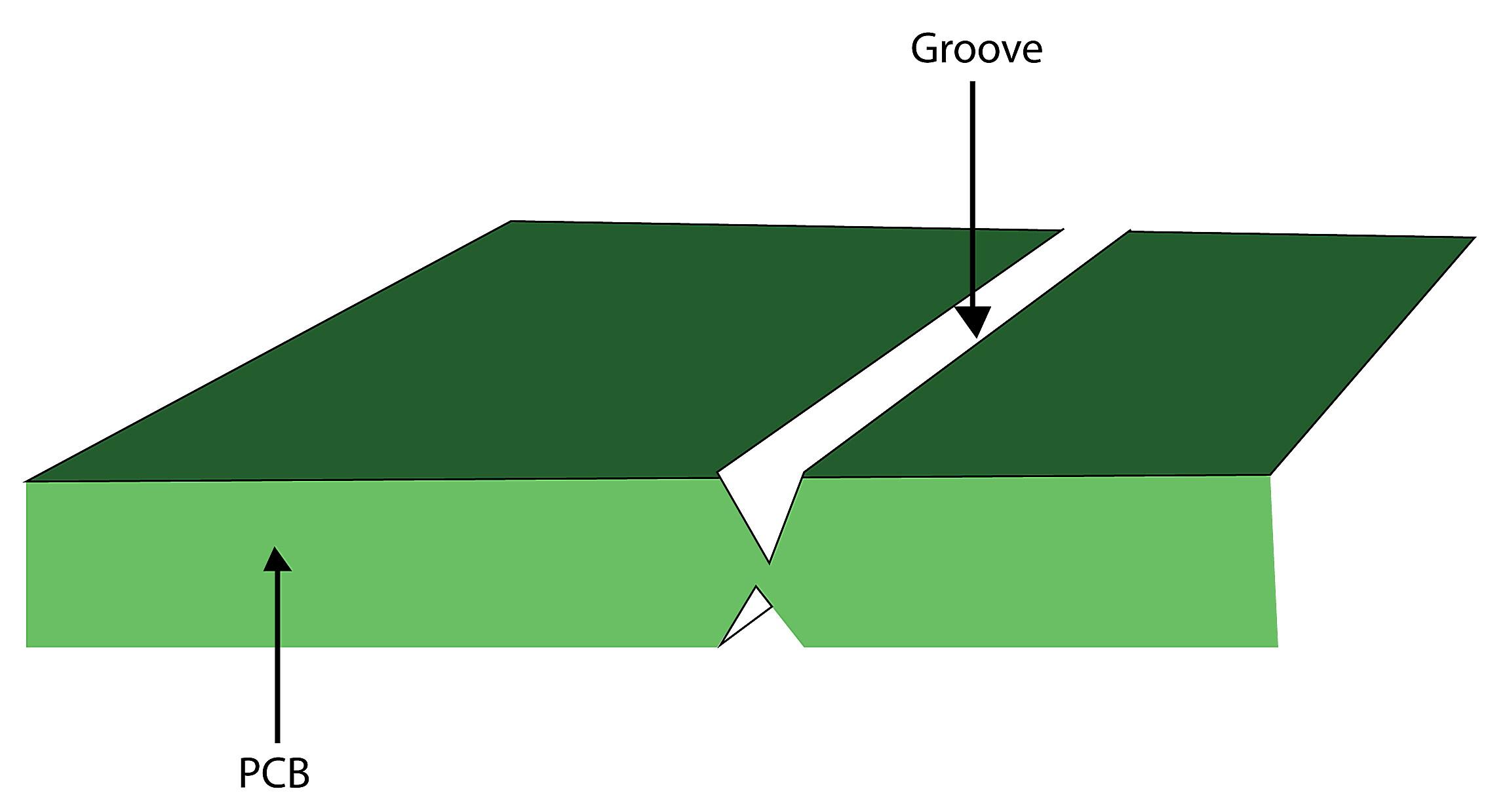

Another consideration is the thickness of the FR4. Thicker boards are generally stronger and more rigid but can also be more expensive and harder to work with. Thinner boards are more flexible but might not be suitable for high-stress applications. Balancing these factors is key to designing a reliable and cost-effective circuit board. If you require flexable board, FR4 might not be for you.

FR4 and the Future

5. The Enduring Legacy of FR4

With the rapid pace of technological advancement, you might wonder if FR4 is destined to become obsolete. Are there new materials on the horizon that will replace it?

While there are certainly alternative materials being developed and used in niche applications, FR4’s combination of performance, cost-effectiveness, and ease of manufacturing makes it difficult to displace completely. It’s likely to remain a mainstay in the electronics industry for the foreseeable future.

However, there is ongoing research to improve FR4’s properties and address some of its limitations. For example, researchers are working on developing FR4 materials with better thermal conductivity and lower dielectric constants. There’s also a growing focus on developing more sustainable and environmentally friendly FR4 formulations.

So, while the basic concept of FR4 may remain the same, expect to see continued innovation and refinement as manufacturers strive to meet the ever-increasing demands of the electronics industry. It is just, there isn’t any better alternative yet. FR4 is here to stay.