What in the World is a Push-In Connector? Let’s Demystify It!

1. So, what are these things?

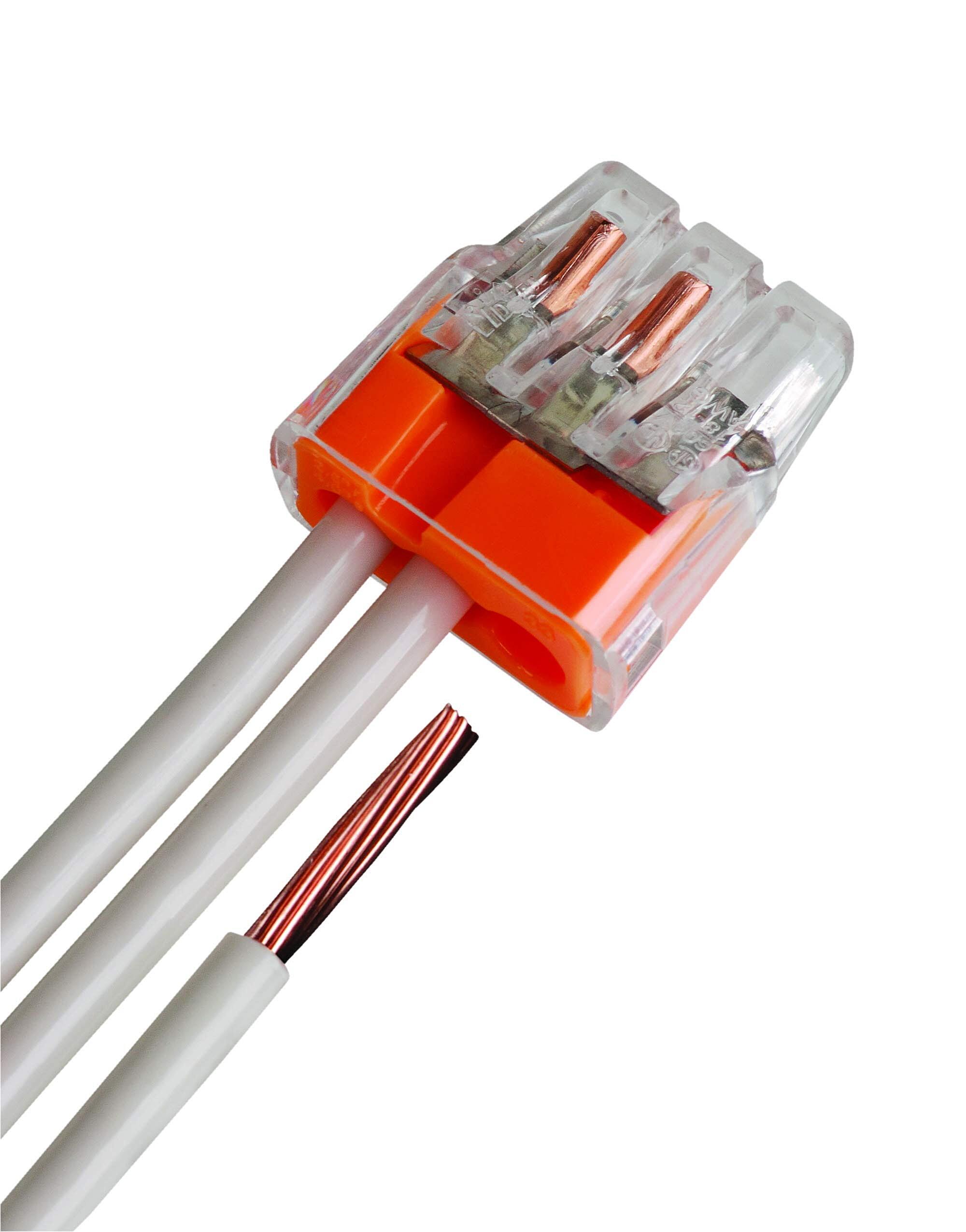

Alright, let’s dive into the world of push-in connectors. Imagine a tiny, hardworking hero of electrical connections, and you’re halfway there. Simply put, a push-in connector is a type of electrical connector that allows you to join wires together without needing to use tools like screwdrivers to tighten screws. Think of it like a quick-release button for wires — you push the wire in, and it’s locked securely in place. No fuss, no muss!

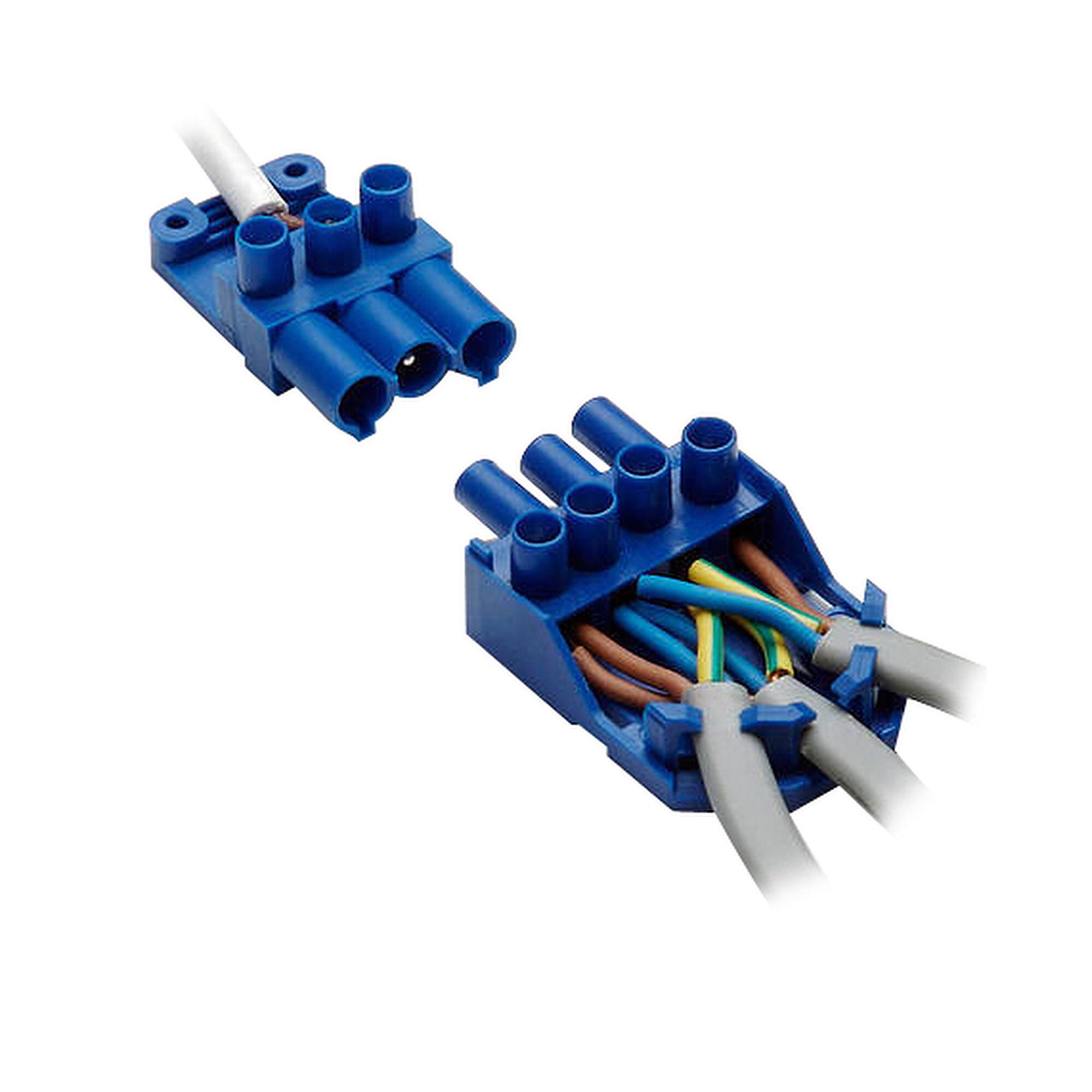

These connectors have become increasingly popular in recent years, and for good reason. They’re fast, reliable, and often take up less space than traditional screw-terminal connectors. This makes them a fantastic option in tight spaces, like inside junction boxes or behind light fixtures.

Now, before you envision tiny robots doing all the work, understand that the “push” action activates an internal spring-loaded mechanism. This mechanism clamps down on the inserted wire, creating a secure and electrically sound connection. It’s clever engineering at its finest.

Think of it this way: Remember those old-school Lego bricks? You pushed them together, and they clicked into place. A push-in connector is a bit like that, but instead of plastic bricks, you’re dealing with electrical wires and a whole lot less childhood nostalgia (unless you’re an electrician, in which case, maybe there is nostalgia!).

Why Should You Even Care About Push-In Connectors?

2. The benefits are Shockingly Good! (Pun Intended)

Okay, so they exist. Big deal, right? Wrong! Push-in connectors offer a whole host of advantages that can make your electrical projects significantly easier and safer. For starters, they drastically reduce the time it takes to make connections. No more fiddling with tiny screws and trying to keep multiple wires in place simultaneously. Just strip, push, and you’re done.

Another significant benefit is improved safety. Screw terminals, if not tightened properly, can lead to loose connections. These loose connections can generate heat, increasing the risk of electrical fires. Push-in connectors, with their consistent clamping force, minimize this risk by ensuring a secure and reliable connection every time. Plus, many have a test point that allows you to check the connection without disconnecting any wires.

Beyond speed and safety, push-in connectors often lead to neater wiring. Their compact size allows for more efficient use of space inside electrical boxes. This is especially helpful in older homes where space is at a premium. A tidy electrical box is a happy electrical box, and a happy electrical box means a happy (and safe!) home.

Think about it: if you’re replacing a light fixture, you can use these connectors to make a quick connection. This is extremely helpful if you’re in a weird position, or need to hold the fixture with your other hand. It makes everything just a little bit easier.

Different Types of Push-In Connectors

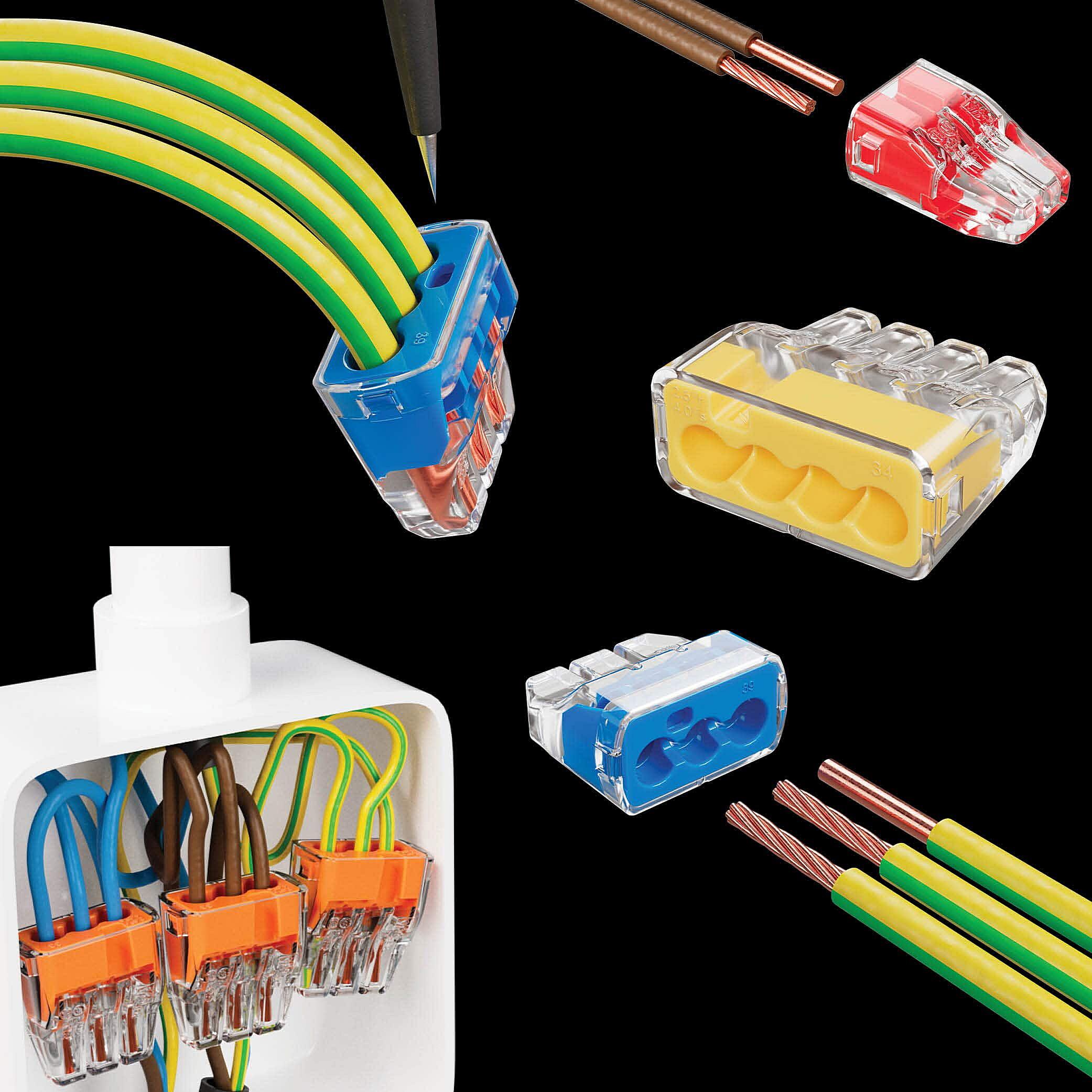

3. Variety is the spice of (electrical) life!

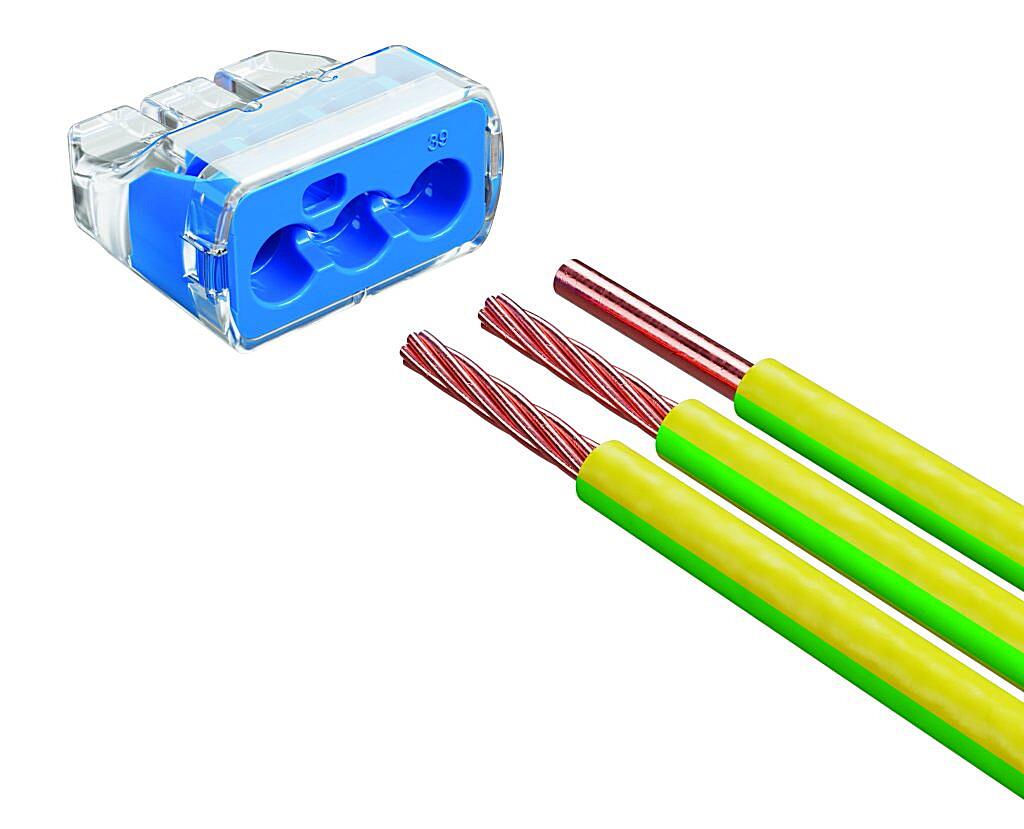

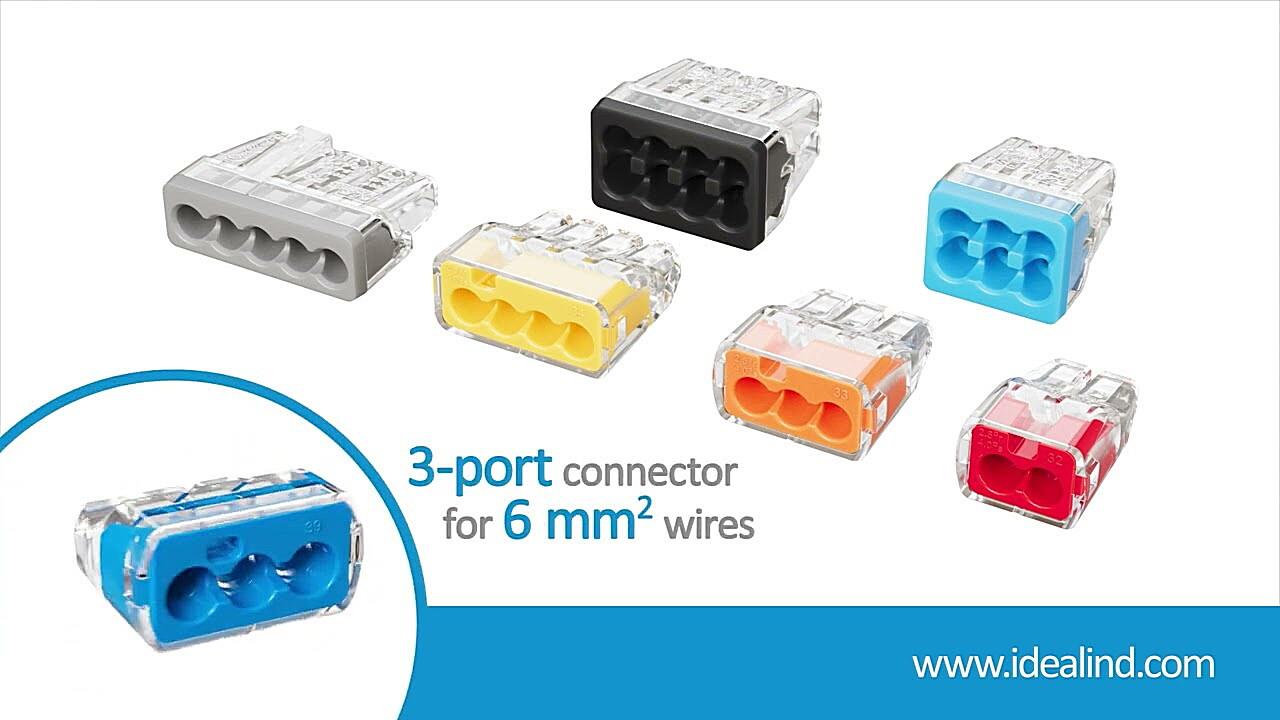

The world of push-in connectors isn’t just a single, monolithic entity. Oh no, there’s variety! Different types of push-in connectors are designed for specific applications and wire gauges. Understanding these differences is crucial to choosing the right connector for your project. Some are designed for solid wires only, some for stranded wires, and some for both. Make sure to check the manufacturer’s specifications before using them.

You’ll find connectors designed for different voltage ratings, too. Make sure the connector you’re using is rated for the voltage of your circuit. Using a connector with a lower voltage rating can be dangerous and could lead to failure or even fire. Think of it like choosing the right size wrench for a bolt; you wouldn’t use a tiny wrench on a huge bolt, would you?

Some push-in connectors also have lever-operated release mechanisms. These allow you to easily remove a wire by simply lifting the lever. This can be incredibly helpful if you need to make changes to your wiring or troubleshoot a circuit. These are usually considered reusable.

Don’t just grab the first connector you see. Take a moment to assess your needs and choose the right type for the job. A little research can save you a lot of headaches (and potentially a lot of sparks!) down the road. Using the correct wire stripper for your wire gauge is important as well to get a nice bare conductor before inserting it into the connector.

How to Use a Push-In Connector

4. A Step-by-Step Guide for the Electrically Challenged (and Everyone Else!)

Alright, let’s get practical. Using a push-in connector is surprisingly simple, but it’s still important to follow a few key steps to ensure a safe and reliable connection. First and foremost, always turn off the power to the circuit you’re working on. This is non-negotiable! Safety first, always.

Next, strip the insulation off the ends of the wires you want to connect. Use a wire stripper to avoid nicking or damaging the copper conductors. The amount of insulation you need to strip will usually be indicated on the connector itself. You don’t want to expose too much or too little conductor.

Now, simply push the stripped wire into the connector until it stops. You should feel a slight resistance as the internal mechanism engages. Give the wire a gentle tug to make sure it’s securely locked in place. If it comes out easily, something’s wrong, and you need to re-do the connection.

That’s it! Seriously. It’s that easy. If you’re using a connector with a lever, simply lift the lever, insert the wire, and release the lever to lock it in place. Always remember to double-check your connections to ensure they are solid and secure. A little extra attention to detail can prevent future problems.

Common Mistakes to Avoid When Using Push-In Connectors

5. Don’t let these slip you up!

Even with their ease of use, there are still a few common mistakes people make when using push-in connectors. One of the biggest is using the wrong size connector for the wire gauge. Using a connector that’s too small can damage the wire, while using one that’s too large can result in a loose connection. Always check the manufacturer’s specifications to ensure compatibility.

Another common mistake is over-stripping the wires. Exposing too much bare conductor can increase the risk of short circuits. Only strip the amount of insulation indicated on the connector. A good rule of thumb is to expose just enough conductor to be fully inside the connector. Better to trim a little more if needed than to have too much exposed.

Forcing a wire that’s too thick into the connector can damage the internal mechanism, compromising the connection. If the wire doesn’t easily push in, don’t force it! You’re probably using the wrong size connector. Using a different connector, or trying again after making sure it’s the right connector, is important.

Finally, resist the urge to reuse push-in connectors that are not designed for reuse. Once a wire has been inserted and removed from a non-reusable connector, the internal mechanism may be weakened, leading to an unreliable connection. While some lever-type connectors are reusable, standard push-in connectors are generally considered single-use. Replacing them is worth the money if you have to rework your connections.

FAQ

6. Because everyone has questions!

Q: Are push-in connectors safe?

A: Absolutely! When used correctly and with appropriately rated connectors, push-in connectors are a safe and reliable way to make electrical connections. They often offer improved safety compared to screw terminals, as they eliminate the risk of loose screws and inconsistent clamping force.

Q: Can I use push-in connectors for all types of wiring?

A: Not necessarily. Some push-in connectors are designed for solid wires only, while others can accommodate stranded wires as well. Check the manufacturer’s specifications to ensure the connector is compatible with the type of wire you’re using. For example, you may not be able to use the same connector for 12 AWG solid core wiring as you would 18 AWG stranded wire.

Q: How do I remove a wire from a push-in connector?

A: It depends on the type of connector. Some connectors have a small release button or slot that you can use to disengage the internal mechanism. Others require you to twist and pull the wire simultaneously. Lever-operated connectors are the easiest; simply lift the lever to release the wire. However, as mentioned before, you cannot reuse a push-in connector that doesn’t have a lever.