You May Also Like :

Understanding Wire Size

1. Decoding the Numbers

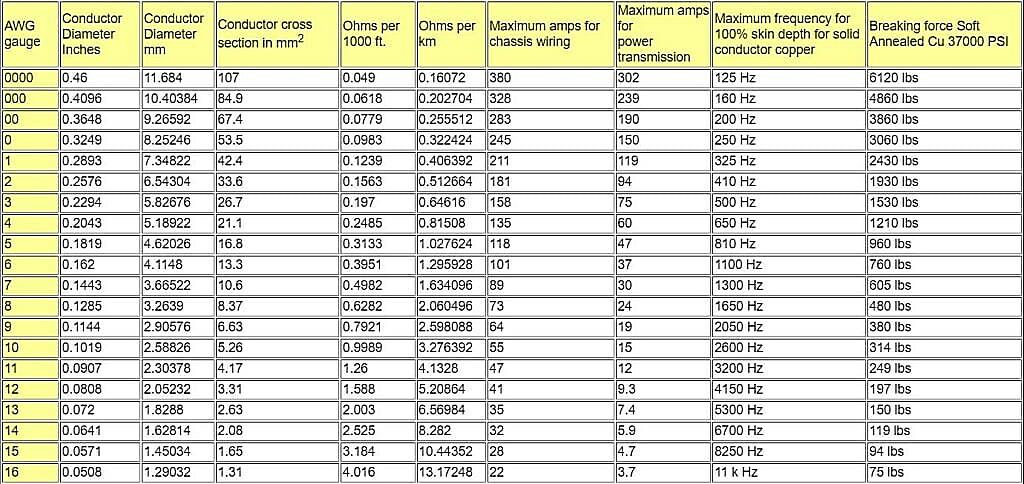

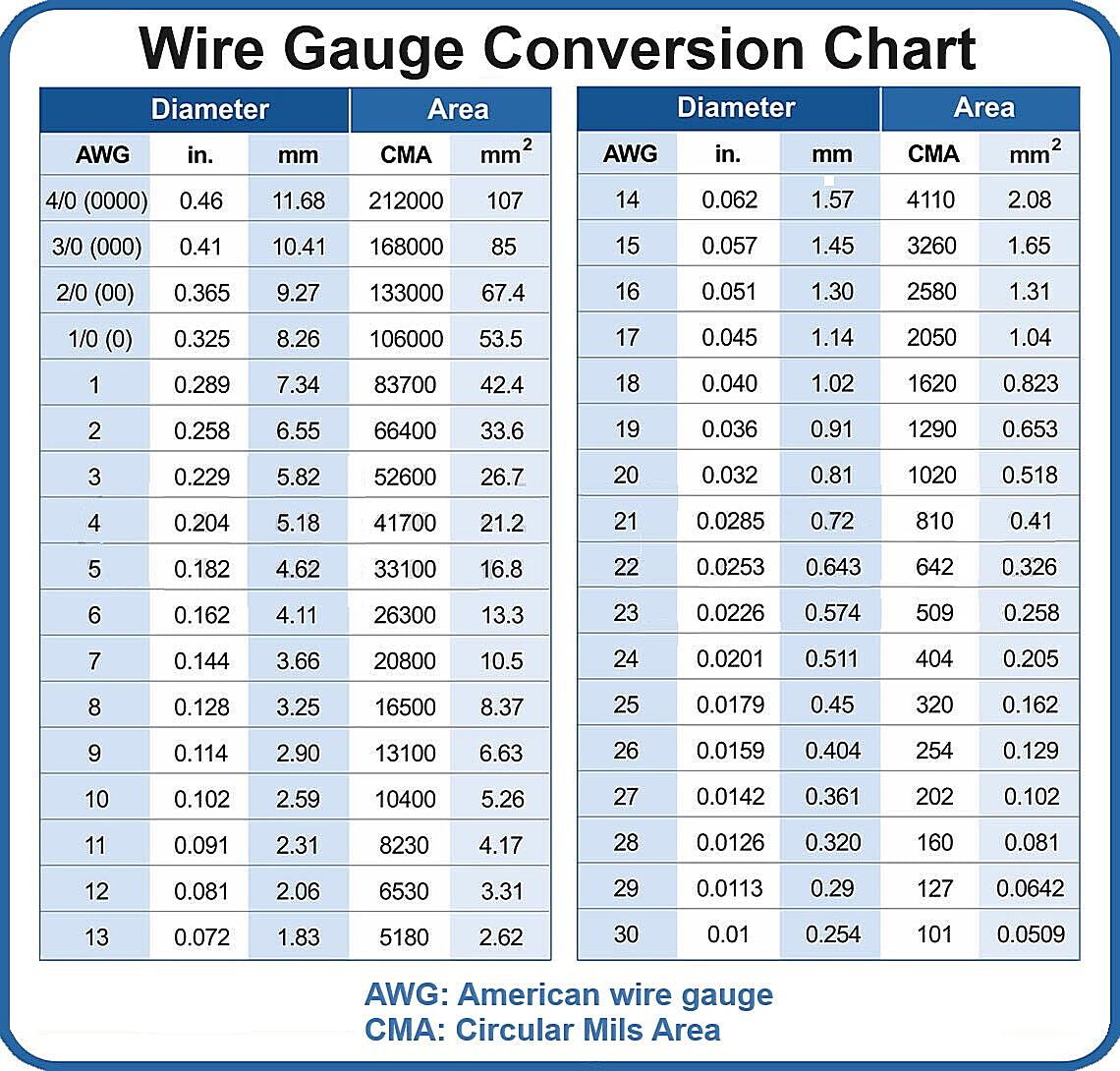

So, you’ve stumbled upon the term “500 wire size” and you’re probably scratching your head, wondering what it all means. Don’t worry, it’s not as complicated as it sounds. In the electrical world, wire sizes are typically measured using the American Wire Gauge (AWG) system. The AWG system uses numbers to represent the diameter of the wire. Seems simple enough, right? Here’s where it gets a little quirky — smaller AWG numbers indicate larger wires, and vice versa. Think of it like golf: a smaller score is better.

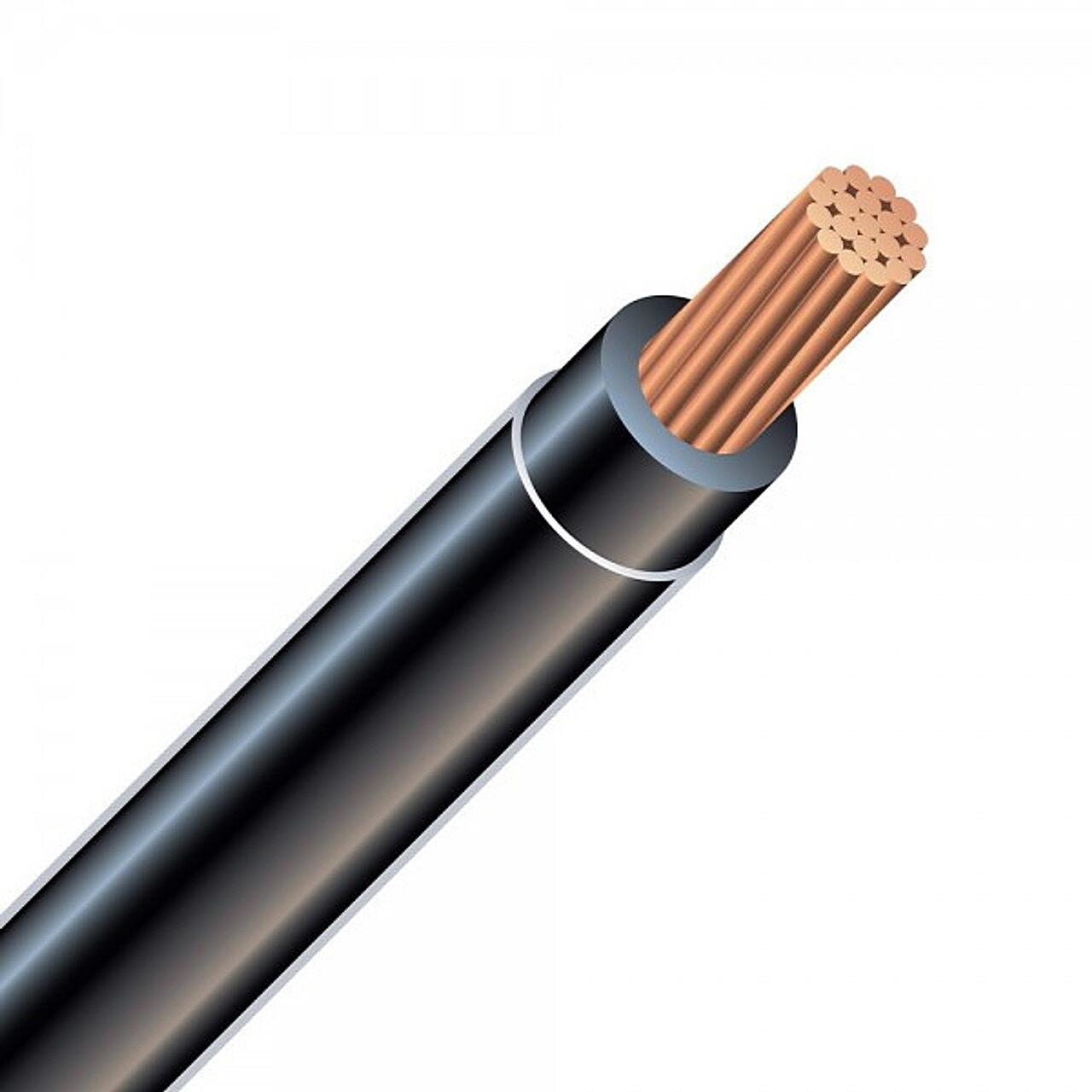

Now, let’s zoom in on our star: the 500 AWG wire. Unlike the AWG numbers you might see on common household wiring (like 12 or 14 gauge), 500 AWG isn’t a single, solid wire. Imagine trying to bend something that thick! Instead, it’s made up of many smaller strands of wire bundled together. This stranded construction makes the wire much more flexible and easier to work with, especially when dealing with high currents.

But back to the number. A 500 AWG wire isn’t actually 500 somethings. It’s a coded designation relating to the wire’s cross-sectional area. It gets more complicated! To be precise, the “500” in “500 AWG” refers to 500 thousand circular mils (kcmil). A circular mil is a unit of area equal to the area of a circle with a diameter of one mil (one thousandth of an inch). So, a 500 kcmil wire has a cross-sectional area of 500,000 circular mils. This large cross-sectional area is what allows it to carry a significant amount of electrical current safely. Think of it like a wide highway allowing lots of cars to pass through at once, versus a small country lane.

In layman’s terms, 500 AWG wire is a beefy conductor designed for heavy-duty electrical applications. It’s the kind of wire you’d find in industrial settings, power distribution systems, or large electrical equipment where high amperage loads are the norm. Its not something youd typically use to wire a lamp in your living room! Imagine trying to fit that into a standard outlet. It would be like trying to park a bus in a bicycle rack.

Why Choose 500 AWG Wire? Current Carrying Capacity and Applications

2. When Do You Need That Much Wire?

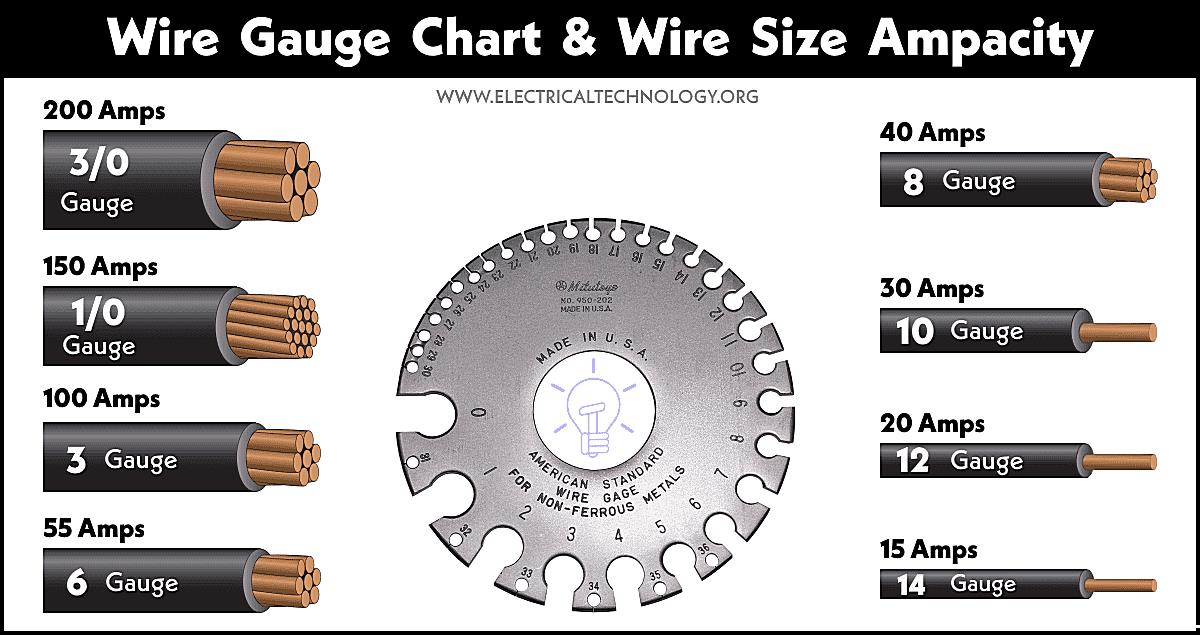

The primary reason someone would choose a 500 AWG wire is its impressive current-carrying capacity. This refers to the maximum amount of electrical current the wire can safely handle without overheating. Overheating can be dangerous, leading to insulation damage, fire hazards, and general electrical mayhem. Larger wires, like our 500 AWG, have lower electrical resistance, which means less heat is generated when current flows through them.

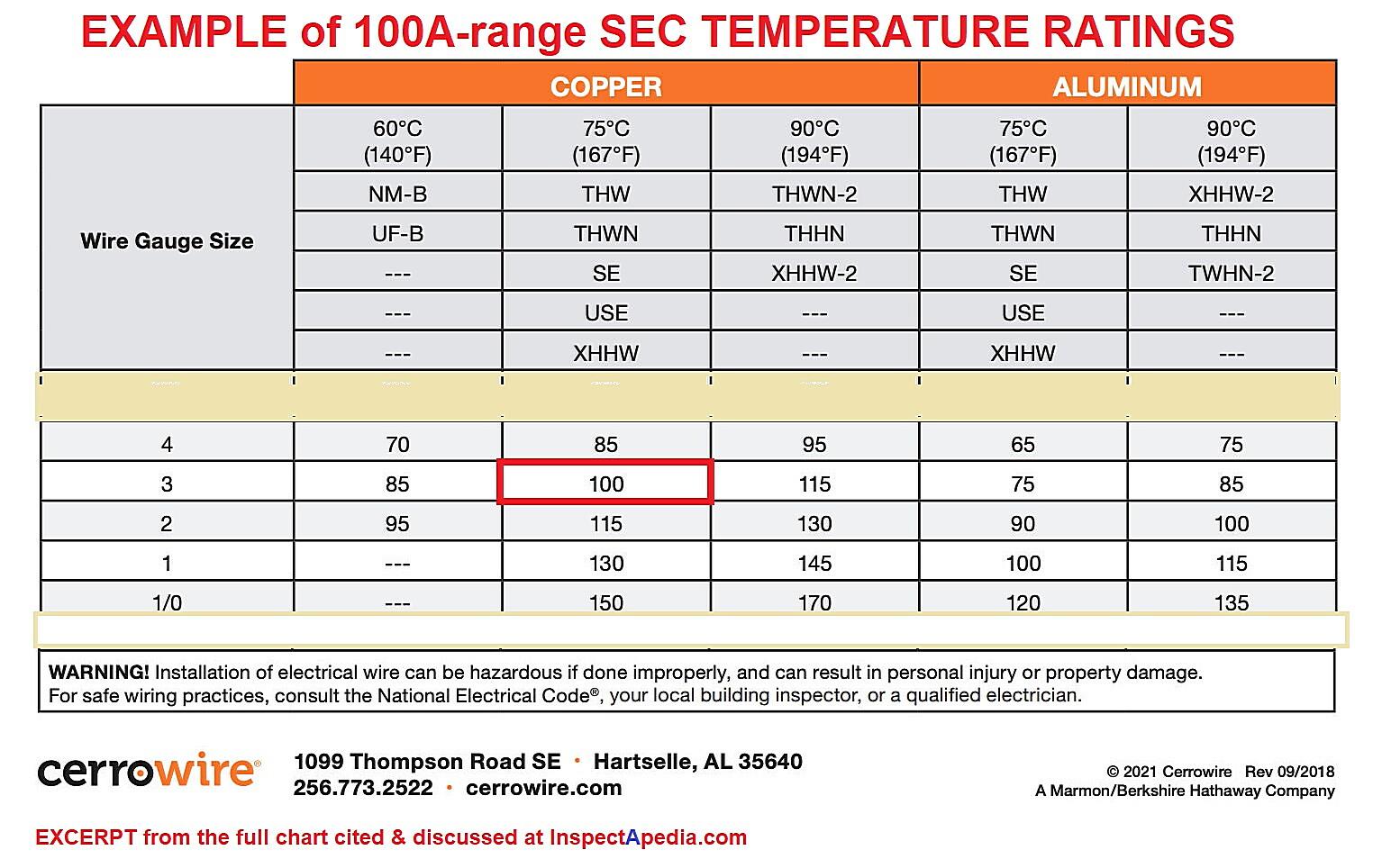

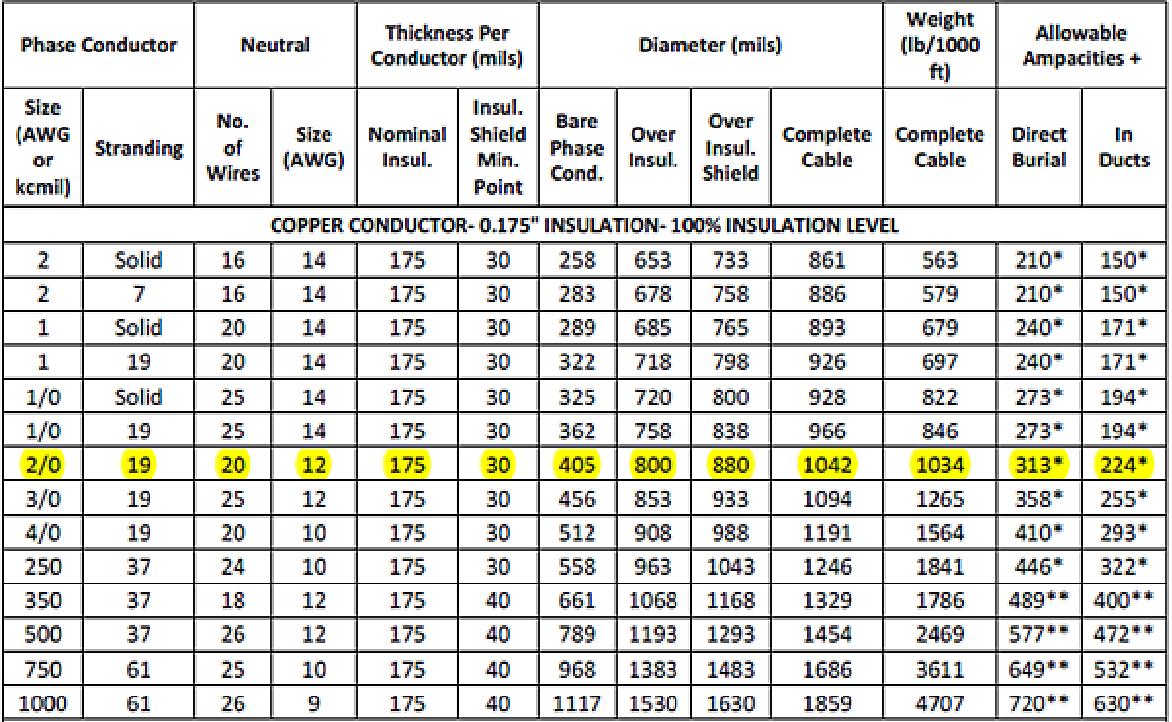

Now, I know what youre thinking: How much current can a 500 AWG wire actually handle? The exact ampacity (current-carrying capacity) depends on several factors, including the type of insulation, the ambient temperature, and how the wire is installed (e.g., in free air or in a conduit). However, generally speaking, a 500 AWG copper wire can handle several hundred amps. Were talking serious power! Always consult the National Electrical Code (NEC) or local electrical codes to determine the specific ampacity for your application.

Where do we find this powerhouse of a wire in the real world? Think big. We’re talking about industrial power distribution, large generators, and main service entrances for commercial buildings. You might also see it in the wiring of heavy machinery, welders, or large electric motors. Essentially, anywhere you need to deliver a lot of power efficiently and safely, a 500 AWG wire is a likely candidate. Its the workhorse of high-current applications.

Using a wire that is too small for the intended load is a recipe for disaster. Undersized wires can overheat, melt their insulation, and potentially start a fire. On the flip side, using a wire that is significantly larger than necessary is simply wasteful and can make installation more difficult due to the wire’s bulk and stiffness. Selecting the appropriate wire size is a balancing act that requires careful consideration of the electrical load, the distance the power needs to travel, and the applicable electrical codes.

Materials Matter

3. Different Metals, Different Performance

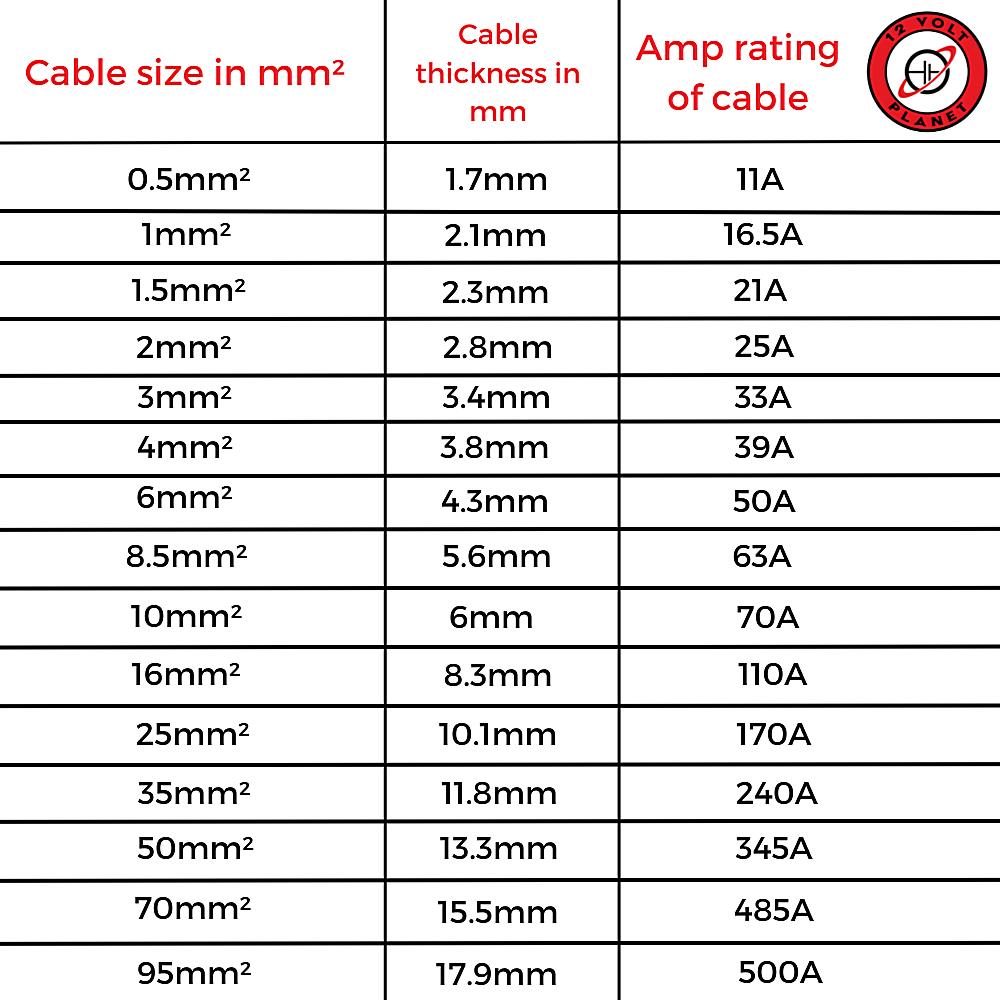

When it comes to 500 AWG wire, you’ll typically find it made of either copper or aluminum. Both materials are excellent electrical conductors, but they have different properties that make them suitable for different applications. Copper is generally considered the superior conductor, offering lower electrical resistance than aluminum for the same wire size. This means copper wires can carry more current and experience less voltage drop over long distances.

However, copper is also more expensive and heavier than aluminum. This is where aluminum 500 AWG wire can offer a cost-effective alternative, especially in applications where weight is a concern or where very long runs of wire are needed. For example, aluminum is often used in overhead power transmission lines because its lighter weight reduces the strain on support structures.

When using aluminum wire, it’s crucial to use appropriately rated connectors and terminals. Aluminum forms an oxide layer on its surface when exposed to air, which can increase resistance and lead to overheating if the connections aren’t properly made. Special anti-oxidant compounds are often used to prevent this oxidation and ensure a secure and reliable connection. Copper, on the other hand, is less prone to oxidation.

So, which material is better for 500 AWG wire? It depends on the specific application and the priorities involved. If performance is paramount and cost is less of a concern, copper is usually the preferred choice. If cost and weight are major considerations, aluminum can be a viable alternative, provided that it’s installed correctly and in accordance with applicable electrical codes. Its all about choosing the right tool for the job.

Installation Considerations for 500 AWG Wire

4. Taming the Beast

Working with 500 AWG wire is not like wiring a lamp. It’s a whole different ball game. Due to its large size and weight, 500 AWG wire can be difficult to handle and manipulate. Specialized tools and techniques are often required to ensure a safe and proper installation. You’re not going to be stripping this with your fingernails!

One of the key considerations is bending radius. Bending a large-gauge wire too sharply can damage the conductor and compromise its current-carrying capacity. Manufacturers typically specify a minimum bending radius for their wires, which should always be followed. Special wire benders may be needed to achieve the correct radius without damaging the wire.

Another important aspect is termination. Properly terminating 500 AWG wire requires the use of heavy-duty connectors and crimping tools. The connection must be mechanically strong and electrically sound to prevent overheating and potential failures. Incorrectly crimped connections are a common cause of electrical problems, so it’s essential to use the right tools and follow the manufacturer’s instructions carefully. Think of it like building a skyscraper — the foundation (the connection) needs to be rock solid.

Finally, safety is paramount when working with any electrical wiring, but especially with high-current applications like those involving 500 AWG wire. Always de-energize the circuit before working on it, and use appropriate personal protective equipment (PPE) such as gloves and safety glasses. If you’re not comfortable working with high-voltage electricity, it’s best to leave it to a qualified electrician. Electricity can be dangerous, and it’s not something to be taken lightly.

Sizing Up Your Needs

5. Don’t Over or Under Do It

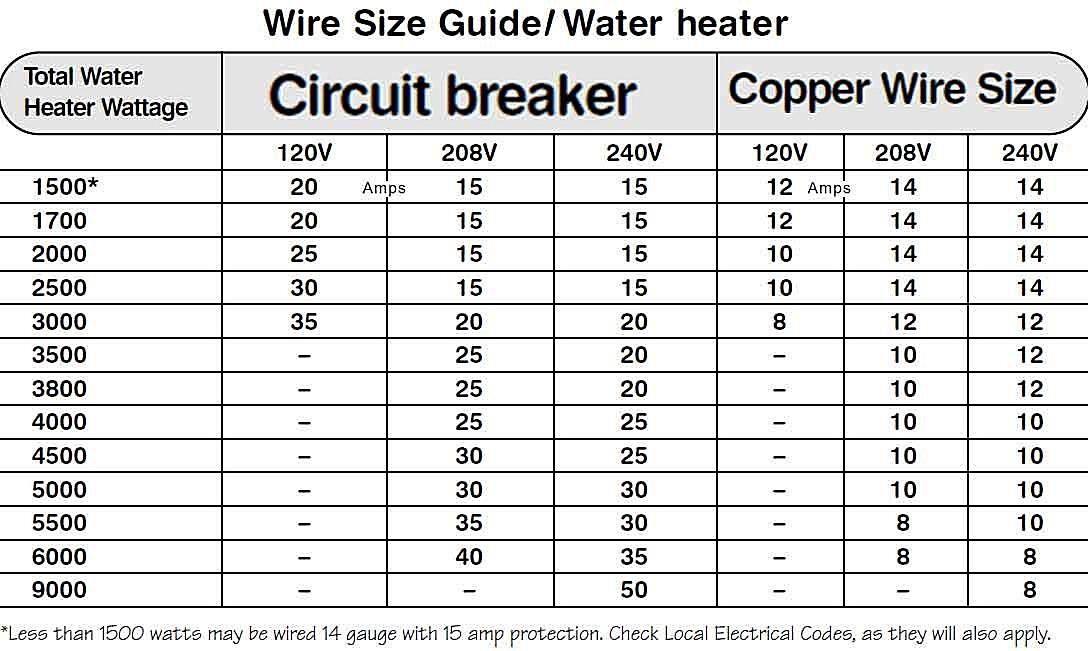

Choosing the right wire size is critical for any electrical installation. Selecting a wire that is too small can lead to overheating and fire hazards, while using a wire that is too large can be unnecessarily expensive and difficult to install. So, how do you determine the appropriate wire size for your application?

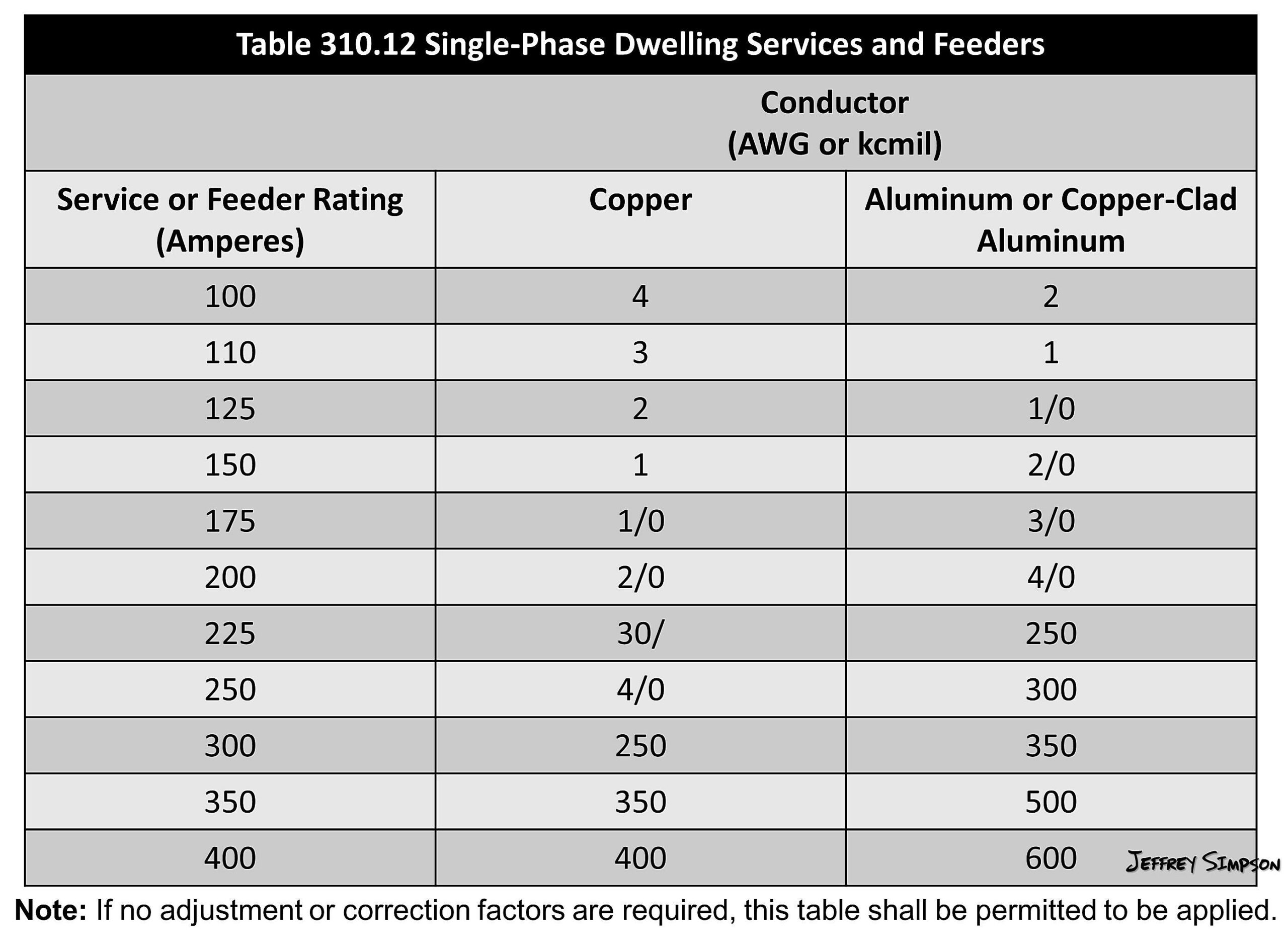

The first step is to calculate the load. This involves determining the amount of current that the circuit will be expected to carry. For example, if you’re wiring a motor, you’ll need to know its full-load current rating. For lighting circuits, you’ll need to add up the wattage of all the lights on the circuit. Once you have the total current, you can use the National Electrical Code (NEC) to determine the minimum wire size required.

The NEC provides tables that list the ampacity of different wire sizes based on their insulation type and installation method. These tables also take into account factors such as ambient temperature and the number of current-carrying conductors in a conduit. It’s important to consult these tables carefully to ensure that you’re selecting the correct wire size. There are also online wire size calculators that can help simplify the process.

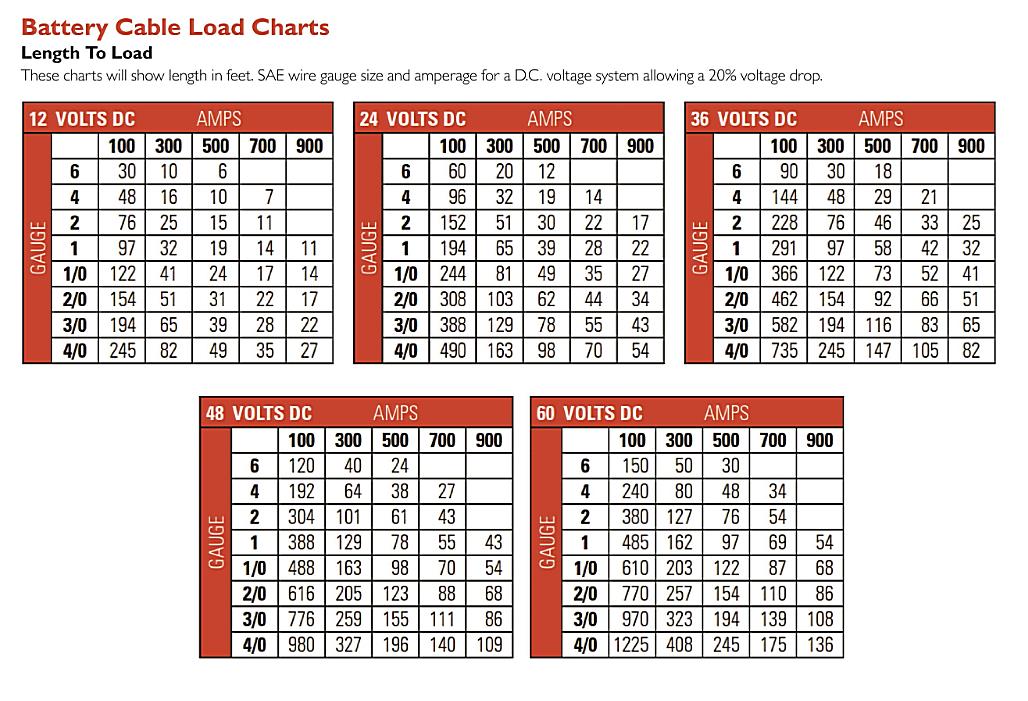

In addition to ampacity, you also need to consider voltage drop. Voltage drop is the decrease in voltage that occurs as electricity travels along a wire. Excessive voltage drop can cause equipment to malfunction and reduce the efficiency of the electrical system. To minimize voltage drop, you may need to increase the wire size, especially for long runs of wire. As a rule of thumb, try to keep voltage drop below 3% for branch circuits and 5% for feeders.

FAQ

6. Your Burning Questions Answered

Let’s tackle some frequently asked questions about 500 AWG wire to clear up any lingering doubts.

Q: What is the diameter of a 500 AWG wire?

A: The overall diameter of a 500 AWG wire varies depending on the insulation type and the manufacturer. However, the bare conductor diameter is approximately 0.813 inches (20.65 mm). Keep in mind that the insulation will add to the overall diameter.

Q: Can I use 500 AWG wire for residential wiring?

A: While technically possible (if your residential service is large enough), it’s highly unlikely that you’d need 500 AWG wire in a typical home. It’s more commonly used in industrial and commercial applications with high current demands. Think of using a fire hose to water your plants.

Q: Is 500 kcmil the same as 500 AWG?

A: Yes! 500 kcmil and 500 AWG refer to the same wire size. The “kcmil” designation is simply another way to express the cross-sectional area of the wire in thousands of circular mils.