Decoding the Mystery

1. Understanding Wire Gauges

Ever looked at wire and wondered about those cryptic numbers they use to describe its thickness? You’re not alone! It’s like a secret code for electronics enthusiasts, hobbyists, and anyone who’s ever tried to wire up a lamp. The gauge of a wire tells you about its diameter, which in turn affects how much current it can safely carry. So, let’s crack this code together, focusing on a specific size: 0.2 mm wire.

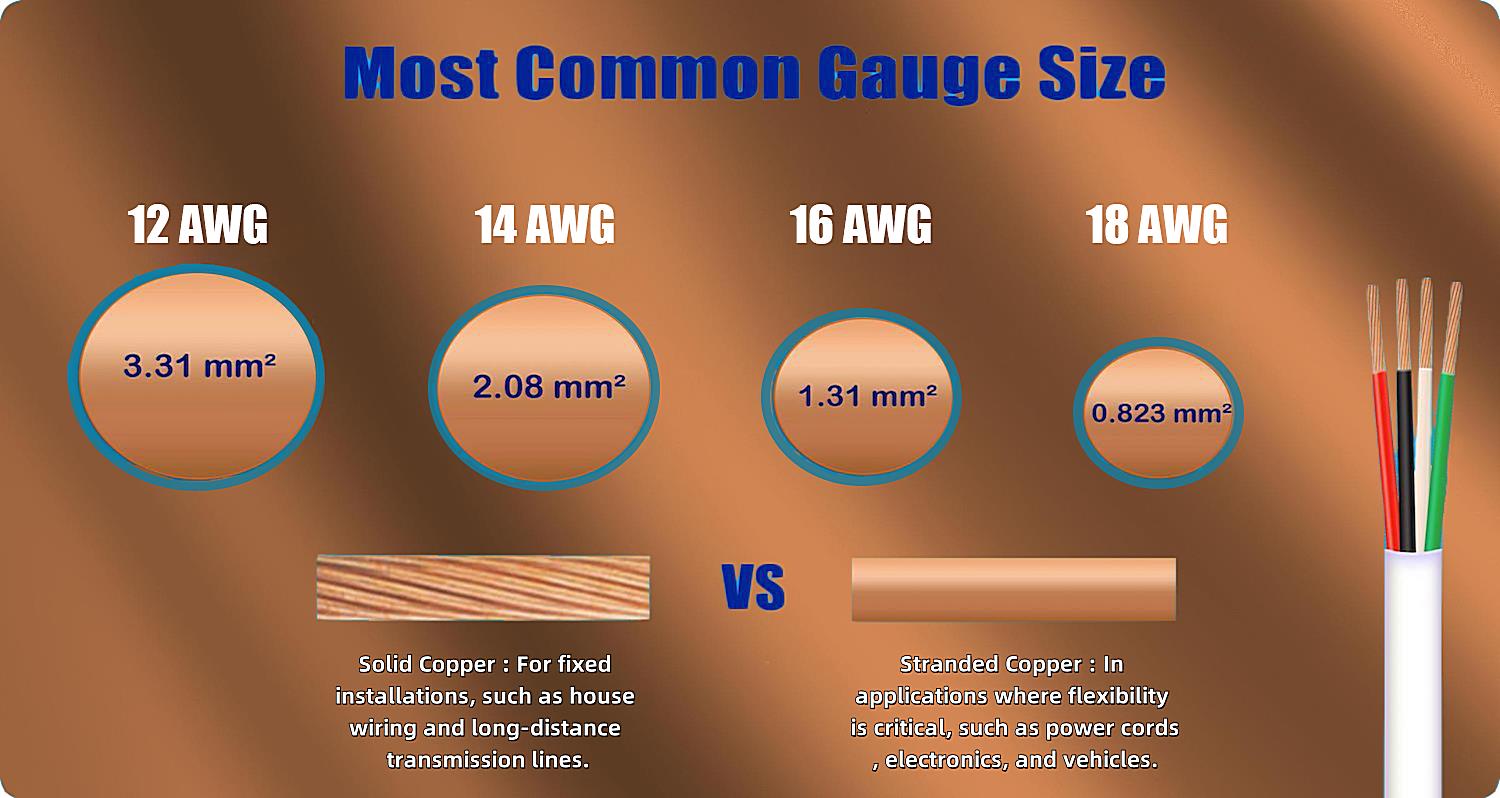

The most common system for measuring wire thickness is the American Wire Gauge (AWG). It might seem counterintuitive at first, but the higher the AWG number, the thinner the wire. Think of it like this: it’s related to the number of times the wire has been drawn through a die to make it thinner. More draws, higher number, skinnier wire. Makes sense, right?

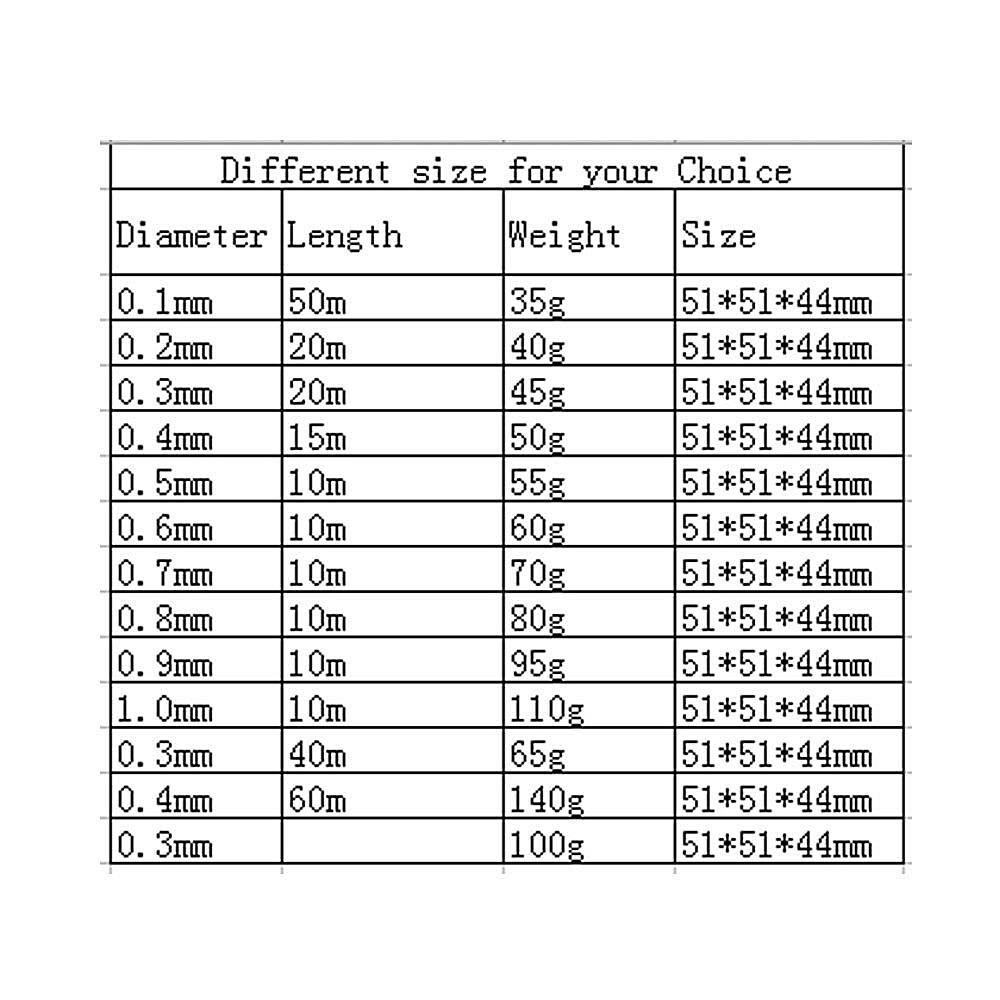

Now, converting from millimeters (mm) to AWG isn’t always a direct, easy peasy calculation. It involves a bit of math, and frankly, most of us prefer to skip the equations and just get to the answer. Luckily, there are handy-dandy conversion charts and calculators available online that can do the heavy lifting for you. So, put down your slide ruler (do people even use those anymore?) and let’s find out what gauge 0.2 mm wire is.

Keep in mind that the relationship between wire gauge and its current carrying capacity is crucial for safety. Using a wire that’s too thin for the amount of current you’re running through it can lead to overheating, melting insulation, and even fire hazards. So, pay attention to those gauge numbers!

The 0.2 mm Wire Gauge Revelation

2. So, What AWG Are We Talking About?

Alright, drumroll please! After consulting those aforementioned handy-dandy conversion tools, we find that 0.2 mm wire is approximately equivalent to AWG 32. Yes, you read that correctly. AWG 32 is a fairly thin wire, often used in delicate electronics projects, breadboarding, and connecting small components. It’s not the kind of wire you’d use for your house wiring, that’s for sure!

It’s important to note that there might be slight variations depending on the specific standard or manufacturer. Some charts might give you a slightly different equivalent, like AWG 31 or 33, but AWG 32 is generally accepted as the closest standard size to 0.2 mm.

Think of 0.2 mm wire as being similar to the thickness of a few human hairs (depending on whose hair we’re talking about, of course!). It’s fine and delicate, so you’ll want to handle it with care. It’s not going to be as robust as a thicker gauge wire, but its small size makes it ideal for certain applications.

Just imagine using this for intricate jewelry making or within tiny circuit boards in your computer! The possibilities are almost limitless, however it has to suit it’s capabilities!

Where Might You Find 0.2 mm (AWG 32) Wire?

3. Applications and Use Cases

So, now that we know 0.2 mm wire is roughly AWG 32, where exactly would you use it? As mentioned earlier, this thin wire is typically found in applications where space is limited, and the current requirements are relatively low. Think of those tiny wires inside your headphones or the internal wiring of a computer mouse.

Here are a few specific examples:

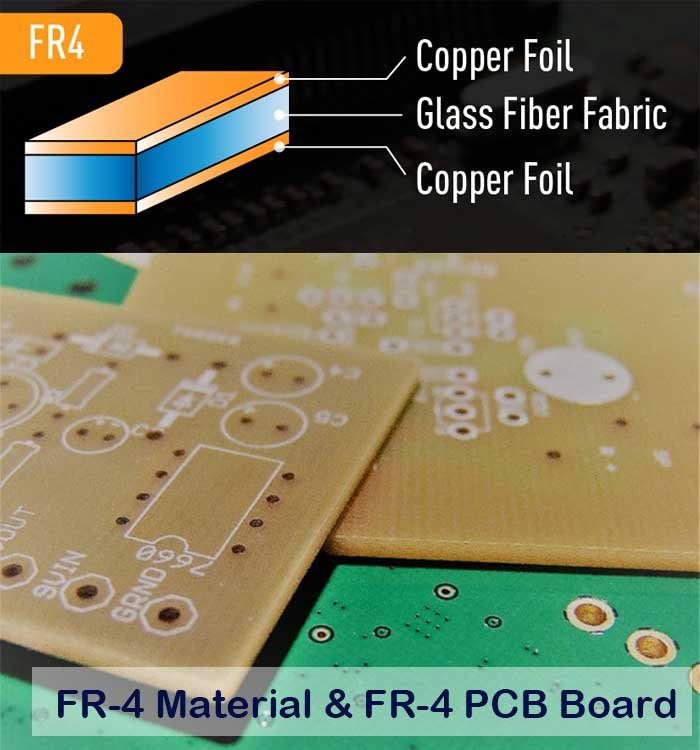

- Electronics Prototyping: AWG 32 wire is a favorite for breadboarding and connecting components on circuit boards. Its flexibility makes it easy to work with in tight spaces.

- Model Railroading: Model railroad enthusiasts often use thin gauge wire like AWG 32 for wiring up miniature lights and accessories on their layouts.

- Jewelry Making: Crafty types might use 0.2 mm wire for delicate wire wrapping and creating intricate jewelry designs.

- Internal Wiring of Small Devices: Anything from sensors to tiny motors might utilize this gauge wire for their internal connections.

Essentially, if you’re working on a project that involves small, low-power components and requires a flexible, easily manageable wire, AWG 32 (0.2 mm) might just be the perfect fit.

Don’t try to power your refrigerator with it, though. It won’t end well.

Safety First

4. Understanding Ampacity and Wire Gauge

We’ve talked about wire gauge and its relationship to thickness, but a crucial factor to consider is the current carrying capacity, also known as ampacity. This refers to the maximum amount of current a wire can safely handle without overheating and potentially causing a fire hazard. Remember, safety is paramount!

The ampacity of a wire depends on several factors, including its gauge, the type of insulation, the ambient temperature, and whether it’s bundled with other wires. For AWG 32 wire, the ampacity is quite low — typically less than 1 amp. This means it’s suitable for low-power circuits and applications only. Exceeding the ampacity rating can be dangerous.

Always consult a wire ampacity chart before starting any electrical project. These charts provide guidelines for the safe current limits for different wire gauges and conditions. A quick search online will reveal plenty of helpful resources. Using the correct wire gauge is crucial for preventing electrical fires and ensuring the longevity of your projects.

Think of it like this: you wouldn’t try to drive a truck down a bicycle path, right? Similarly, you wouldn’t try to push a large amount of current through a tiny wire. Use the right tool (or wire) for the job!

Choosing the Right Wire

5. Other Factors to Consider

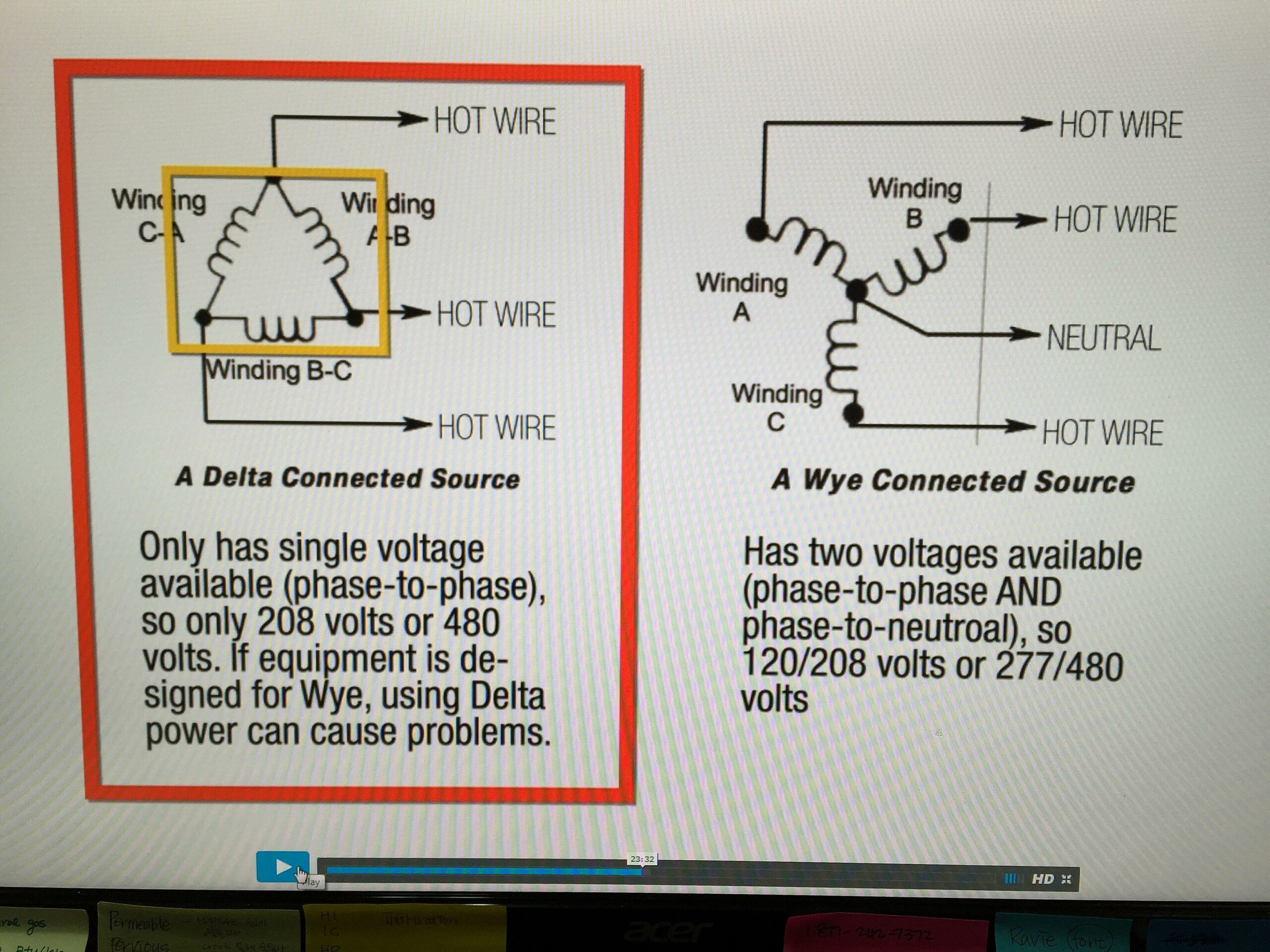

While knowing the gauge of the wire (like our 0.2 mm example) is essential, it’s not the only factor to consider when choosing the right wire for your project. You also need to think about things like the type of insulation, the material of the conductor (copper, aluminum, etc.), and the environment in which the wire will be used.

For example, if you’re working on a project that will be exposed to high temperatures, you’ll need to choose a wire with heat-resistant insulation. If you’re working in a corrosive environment, you’ll want to select a wire with corrosion-resistant properties. And if you need a flexible wire for a project that involves a lot of movement, you’ll want to choose a stranded wire rather than a solid core wire.

Copper is generally the preferred conductor material for most electrical applications due to its excellent conductivity and resistance to corrosion. Aluminum is a less expensive option, but it’s not as conductive as copper, and it requires larger gauge wires to carry the same amount of current.

So, before you grab that spool of 0.2 mm (AWG 32) wire, take a moment to consider all the factors involved. Choosing the right wire will ensure the safety, reliability, and longevity of your project.