Decoding BMS and PLC

1. The Basic Buzz on Building Management Systems (BMS)

Ever walked into a modern office building and felt that perfectly comfortable temperature, like Goldilocks’ porridge just right? Chances are, a Building Management System, or BMS, is pulling the strings behind the scenes. Think of a BMS as the central nervous system of a building, constantly monitoring and controlling things like HVAC (heating, ventilation, and air conditioning), lighting, security, and even energy usage. It’s all about efficiency and creating a comfortable, safe environment. It’s not just about flicking switches; it’s about intelligent automation.

Imagine a scenario where a room gets too hot during the day due to direct sunlight. A BMS would detect this temperature increase and automatically adjust the cooling system in that specific zone. Or, if motion sensors don’t detect any activity in a conference room after a certain hour, the BMS might dim the lights to save energy. It’s proactive, responsive, and designed to optimize building performance.

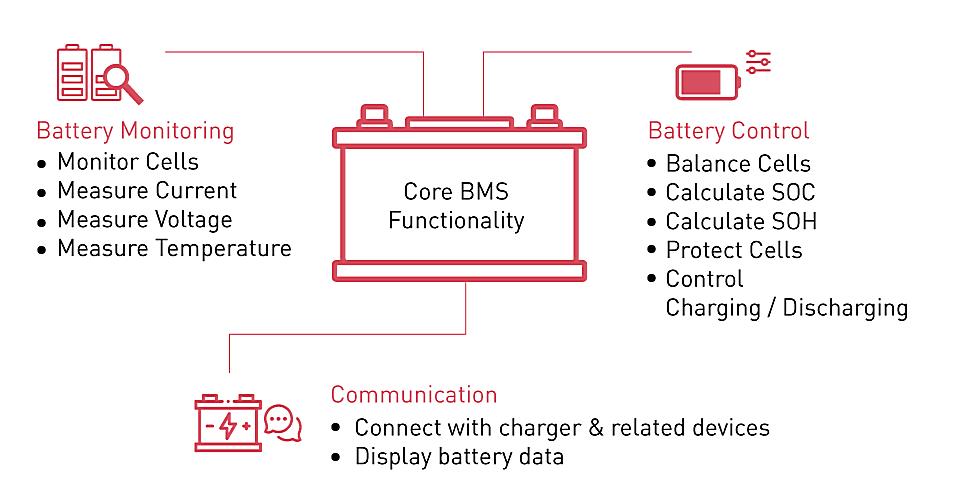

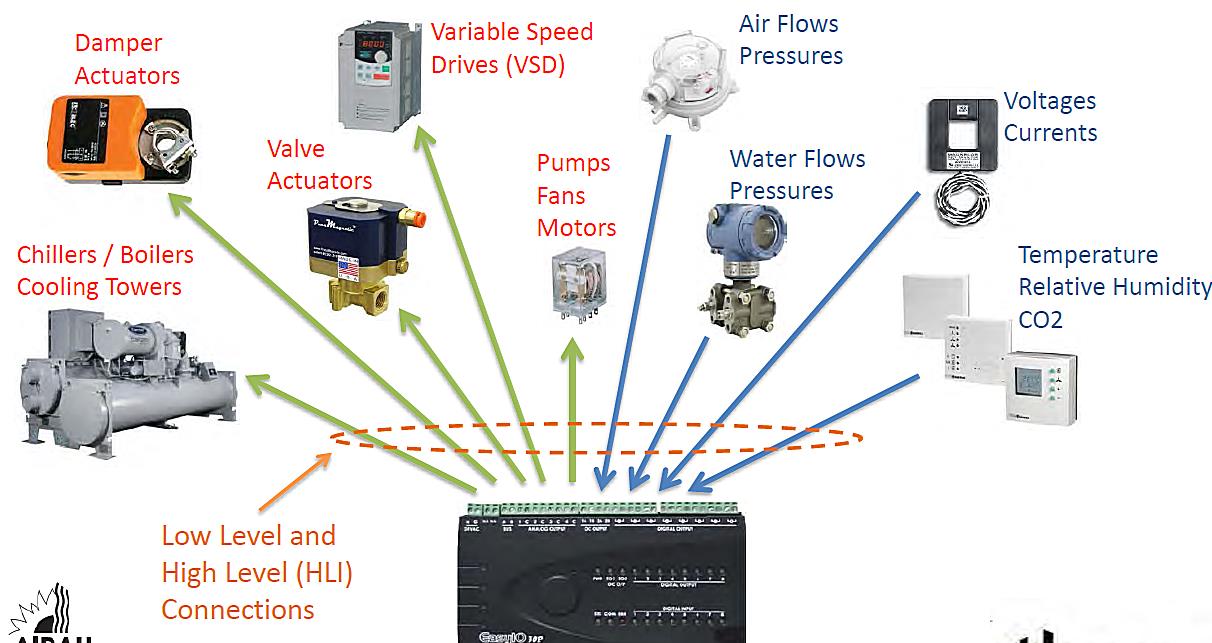

So, what makes up a BMS? It’s a combination of hardware (sensors, controllers, actuators) and software that work together. Sensors gather data, controllers process it, and actuators carry out the commands. The software acts as the brain, providing a user interface for monitoring and making adjustments. It’s quite a symphony of technology, orchestrated for the benefit of building occupants and owners.

A well-implemented BMS can lead to significant cost savings through reduced energy consumption, improved maintenance scheduling, and early detection of potential problems. Plus, a comfortable and safe environment can boost productivity and create a better experience for everyone. Who wouldn’t want that?

2. Peeking Under the Hood of Programmable Logic Controllers (PLC)

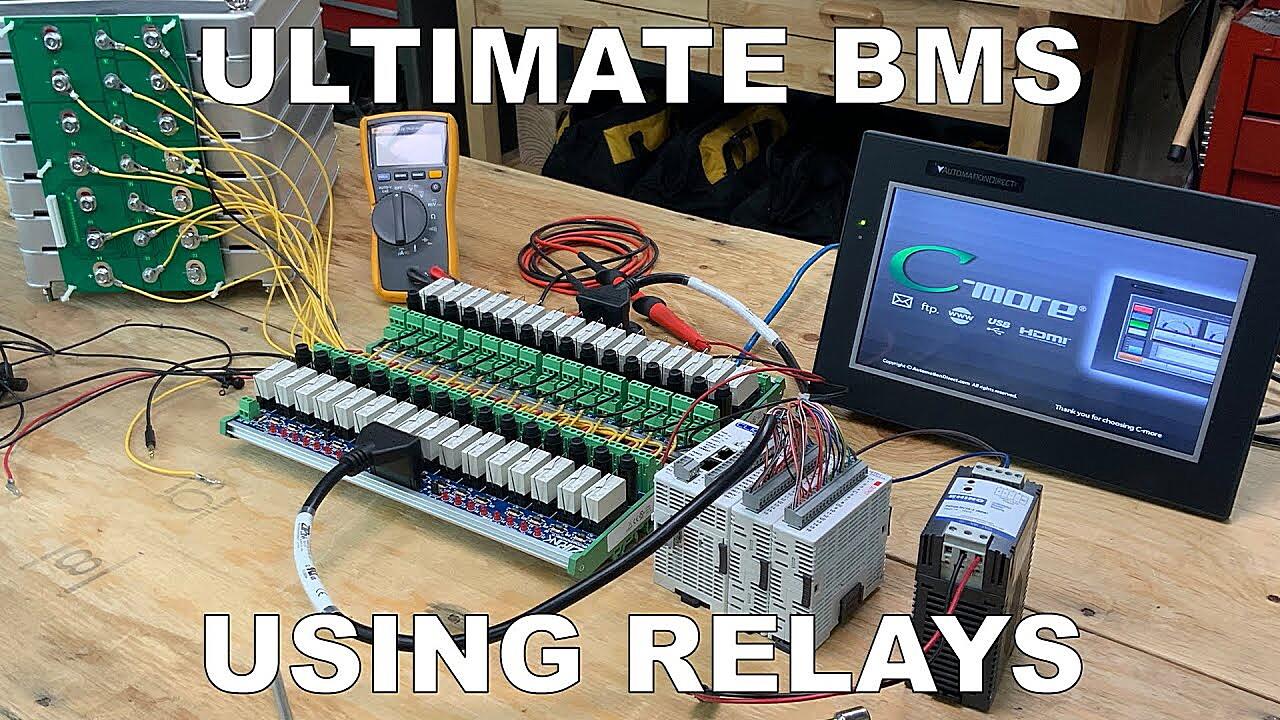

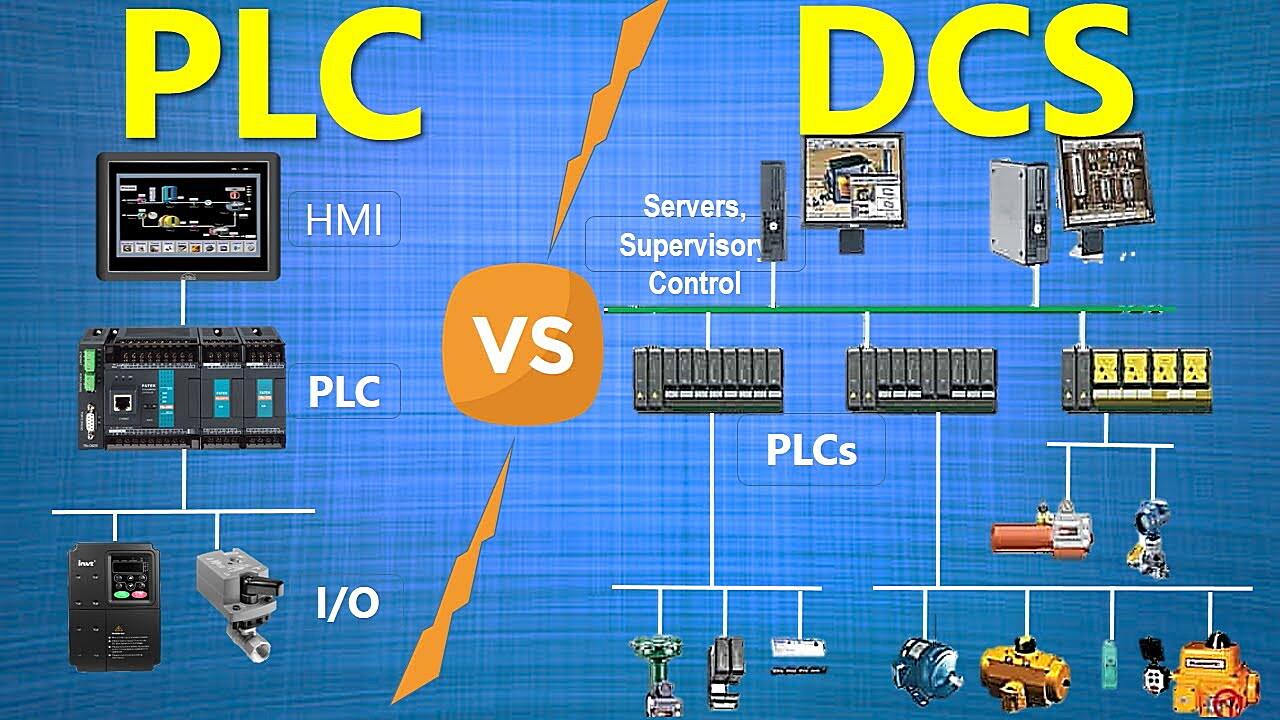

Now, let’s shift gears and talk about Programmable Logic Controllers, or PLCs. These little guys are the workhorses of industrial automation. Think of them as the brains behind everything from assembly lines and robotic arms to traffic lights and amusement park rides. They’re built for rugged environments and designed to handle complex control tasks with precision and reliability.

Unlike a general-purpose computer, a PLC is specifically designed for real-time control of industrial processes. They operate based on inputs (signals from sensors or switches), process those inputs according to a pre-programmed logic, and then generate outputs (signals to control motors, valves, or other devices). It’s all about speed, accuracy, and dependability in demanding conditions.

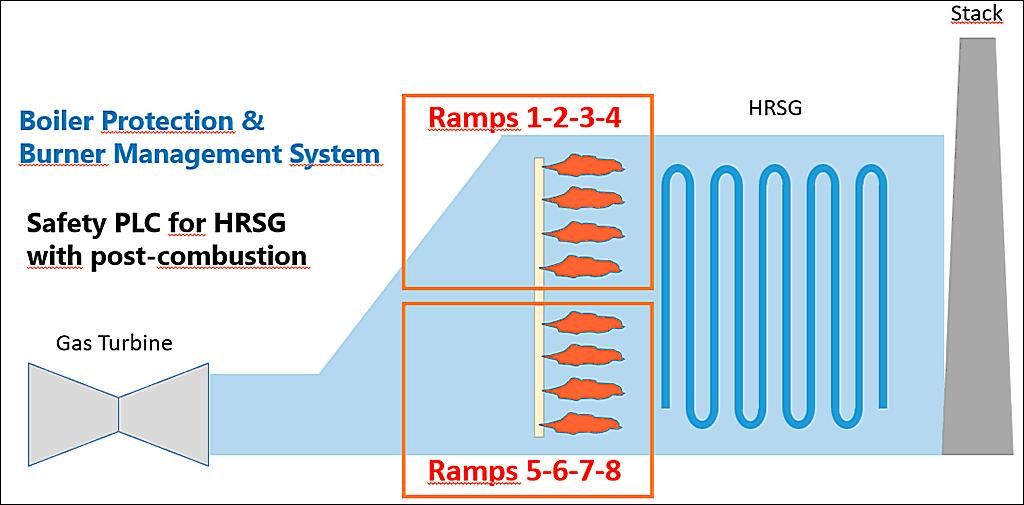

PLCs are often used in manufacturing plants to automate repetitive tasks, monitor equipment performance, and ensure product quality. They can also be found in water treatment plants, power generation facilities, and even in some sophisticated home automation systems. Their versatility and robustness make them a popular choice for a wide range of industrial applications.

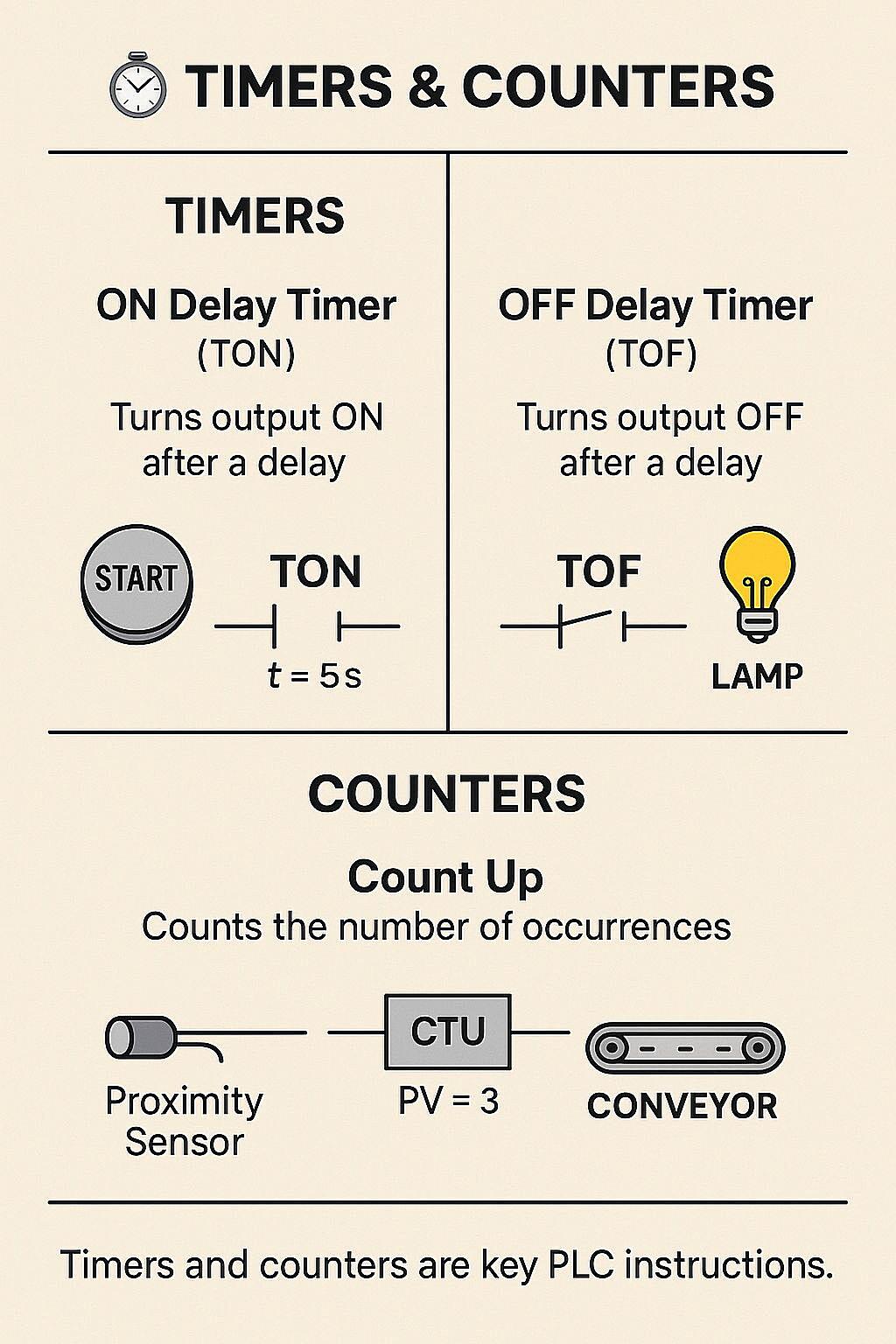

The beauty of a PLC lies in its programmability. Instead of hard-wired relays and timers, a PLC uses software to define the control logic. This makes it much easier to modify and update the control system as needed. It’s like having a Lego set for automation, allowing you to build and reconfigure your control system as your needs change.

The Key Differences

3. Dissecting the Core Functionalities

Okay, so now that we have a basic understanding of BMS and PLC systems, let’s dive into the key differences. While both involve control and automation, they operate in different realms. A BMS is primarily focused on managing and optimizing building environments, while a PLC is geared towards controlling industrial processes. Think of it like this: a BMS manages the comfort of the people inside, while a PLC manages the machinery and processes that create the products or services.

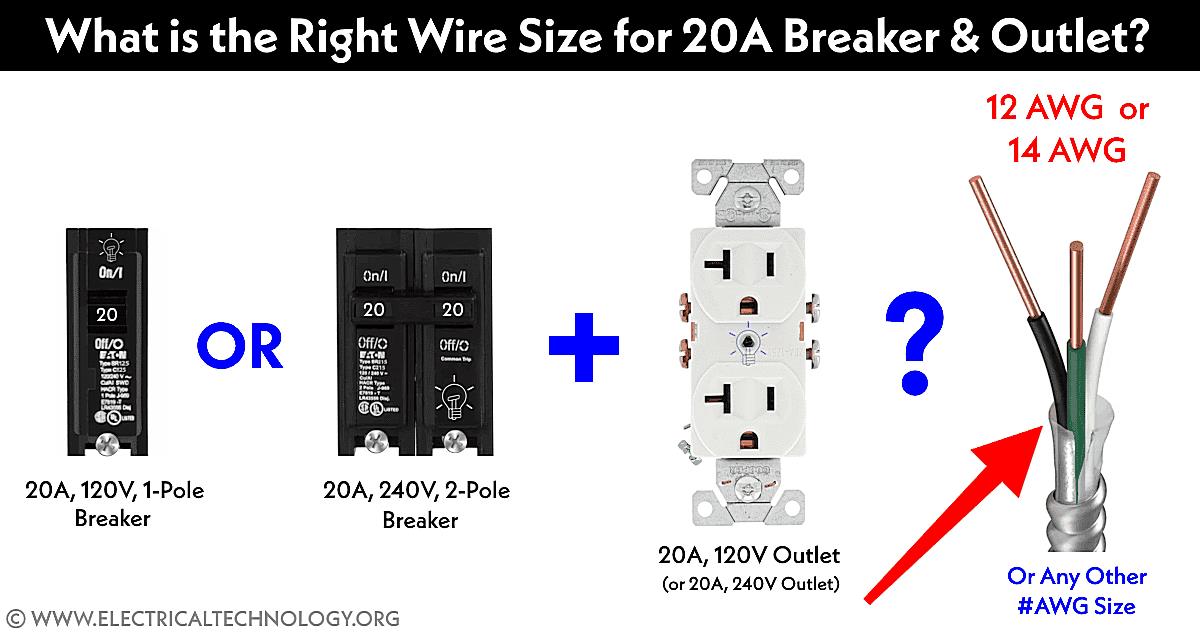

The inputs and outputs also differ. A BMS typically deals with inputs like temperature sensors, occupancy sensors, and air quality sensors, and outputs like HVAC systems, lighting controls, and security systems. A PLC, on the other hand, often deals with inputs like pressure sensors, flow meters, and limit switches, and outputs like motors, valves, and robotic actuators. It’s all about the specific application.

Another important difference is the programming language. BMS systems often use proprietary software and programming languages, while PLCs typically use standardized languages like ladder logic, function block diagrams, and structured text. This difference reflects the different levels of complexity and the need for specialized expertise.

Even their typical operating environments differ greatly. BMS are usually found in offices, hospitals, schools, and other commercial buildings. PLCs are installed at manufacturing plants, water treatment facilities, chemical factories, and other industrial sites. The differences show in their construction, components, and durability.

4. Use Cases

To really hammer home the differences, let’s look at some specific use cases. Imagine a hospital. A BMS would be responsible for maintaining a comfortable and sterile environment in operating rooms, controlling access to sensitive areas, and monitoring energy consumption throughout the building. It’s all about patient comfort, safety, and efficiency.

Now, imagine a bottling plant. A PLC would be responsible for controlling the entire bottling process, from filling the bottles to capping them to labeling them. It would also monitor the speed of the conveyor belts, the pressure of the filling nozzles, and the temperature of the liquids. Its main concern is process efficiency, quality, and consistency.

You might find a BMS monitoring the temperature and humidity in a data center, while a PLC controls the precision movements of robotic arms on an assembly line. While both are controlling automated systems, the goals and the methods are quite distinct.

In a modern “smart building,” you might even see both systems working together. The PLC could control the manufacturing processes within a specific part of the building, while the BMS manages the overall building environment. They might even communicate with each other to optimize energy usage and improve overall building performance. The BMS might use information from the production schedule (controlled by the PLC) to adjust the HVAC settings in that area, for example.

Can They Ever Be Friends? Integration Possibilities

5. Bridging the Gap for Enhanced Functionality

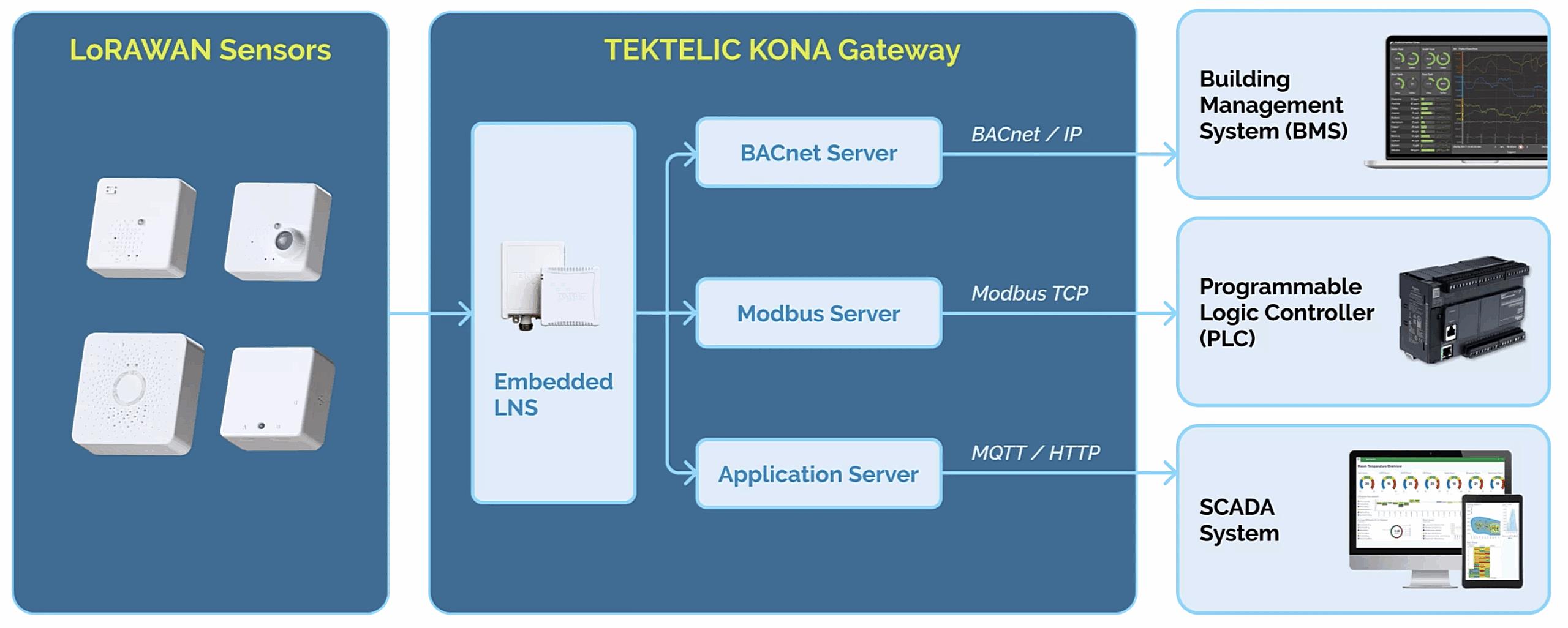

So, are BMS and PLC destined to remain in their separate worlds? Not necessarily. While they have different primary functions, there are increasing opportunities for integration. By connecting the two systems, you can unlock new levels of efficiency, control, and insight. Imagine a scenario where a BMS can access data from a PLC to optimize energy consumption based on real-time production demands.

For example, if a manufacturing plant is running at full capacity, the BMS could automatically adjust the HVAC system to maintain a comfortable temperature for the workers. Or, if the PLC detects a malfunction in a piece of equipment, it could alert the BMS to shut down the affected area and prevent further damage. It’s all about creating a more holistic and responsive building management system.

However, integrating BMS and PLC systems can be a complex undertaking. It requires careful planning, specialized expertise, and a thorough understanding of both systems. The communication protocols and data formats may be different, so it’s important to choose compatible hardware and software. Security is also a critical consideration, as any integration could create new vulnerabilities.

The benefits of integrating BMS and PLC systems can be significant, especially in industrial buildings and facilities. By combining the strengths of both systems, you can create a more efficient, resilient, and sustainable environment. It’s all about leveraging technology to optimize building performance and improve the overall experience for occupants and operators.

Putting It All Together

6. BMS and PLC

To sum it up, while both BMS and PLC systems are involved in automation and control, they serve distinct purposes and operate in different environments. A BMS is focused on managing building environments, while a PLC is focused on controlling industrial processes. Think of it like the difference between managing a household and running a factory — similar principles, but very different scales and priorities.

However, the lines are blurring as technology advances and the demand for integrated solutions grows. By connecting BMS and PLC systems, you can unlock new levels of efficiency, control, and insight. But it’s important to approach integration with caution and a clear understanding of the challenges and opportunities.

So, the next time you hear someone mention BMS and PLC, you’ll know that they’re not the same thing, but they can certainly work together to create a more intelligent and connected world. And that’s something to get excited about!

Ultimately, the choice between a BMS, a PLC, or an integrated system depends on your specific needs and goals. Consider the environment, the application, the level of complexity, and the available resources. With careful planning and the right expertise, you can choose the solution that’s right for you.

FAQ

7. Question

While technically possible, it’s generally not recommended. PLCs are designed for industrial environments and may not be the best choice for managing all aspects of a building. A dedicated BMS is usually a better option for overall building management.

8. Question

The cost of integration can vary depending on the complexity of the project and the specific hardware and software involved. It’s important to carefully assess the costs and benefits before making a decision. Get quotes and talk to experts. Its not always cheap, but the long-term benefits can outweigh the upfront investment.

9. Question

Security is a critical consideration for both BMS and PLC systems. It’s important to implement appropriate security measures, such as firewalls, intrusion detection systems, and regular security audits. Neglecting security can lead to serious consequences, including data breaches, system disruptions, and even physical damage.