You May Also Like :

Understanding Splice Connectors

1. What are Splice Connectors and Why Use Them?

So, you’re staring at some wires and thinking, “There has to be a better way than twisting these things together and hoping for the best.” You’re absolutely right! That’s where splice connectors come in. Think of them as tiny, efficient bridges that create solid, reliable connections between wires. No more dodgy connections that flicker the lights when you turn on the toaster.

Why bother with splice connectors? Well, for starters, they’re safer than the old twist-and-tape method. They provide a secure, insulated connection that reduces the risk of shorts, sparks, and other electrical gremlins. Plus, they’re much neater and easier to work with, especially in tight spaces. Imagine trying to wrangle wires behind a dashboard splice connectors are a lifesaver!

Beyond safety and convenience, splice connectors also offer better conductivity. A solid connection ensures that electricity flows smoothly and efficiently, which can improve the performance of your electrical system. And let’s be honest, who doesn’t want their electronics running at their best?

Finally, using splice connectors gives your work a professional touch. It shows you care about doing things right and that you’re not just slapping things together. It’s the difference between a house built with care and one that looks like it might fall down in the next stiff breeze. And isn’t that something we all strive for?

Choosing the Right Splice Connector

2. Picking the Perfect Connector

Okay, so you’re sold on splice connectors. Great! But not all connectors are created equal. Choosing the right one depends on a few key factors, like the wire gauge (thickness), the type of wire (solid or stranded), and the environment where the connection will be located. Using the wrong connector can lead to a faulty connection or even damage your wires, so it’s worth taking the time to get it right.

Wire gauge is crucial. Each connector is designed for a specific range of wire sizes. Using a connector that’s too small can crush the wire, while one that’s too large won’t make a secure connection. Check the connector’s packaging for the recommended wire gauge range, and be sure to match it to the wires you’re using. Imagine trying to fit a square peg in a round hole; you’ll just end up frustrated!

Consider the environment. Will the connection be exposed to moisture, extreme temperatures, or vibrations? If so, you’ll need a connector that’s designed to withstand those conditions. Waterproof connectors are a must for outdoor applications, while high-temperature connectors are ideal for engine compartments. Think of it like choosing the right shoes for the weather; you wouldn’t wear sandals in the snow, would you?

Don’t forget about accessibility. Some connectors are easier to install and remove than others. If you anticipate needing to make changes to the connection in the future, choose a connector that’s designed for easy access. Spring connectors, for example, are quick and easy to use, while crimp connectors require a bit more effort. It’s all about finding the right balance between security and convenience. Its like choosing between velcro and shoelaces, each has its advantages!

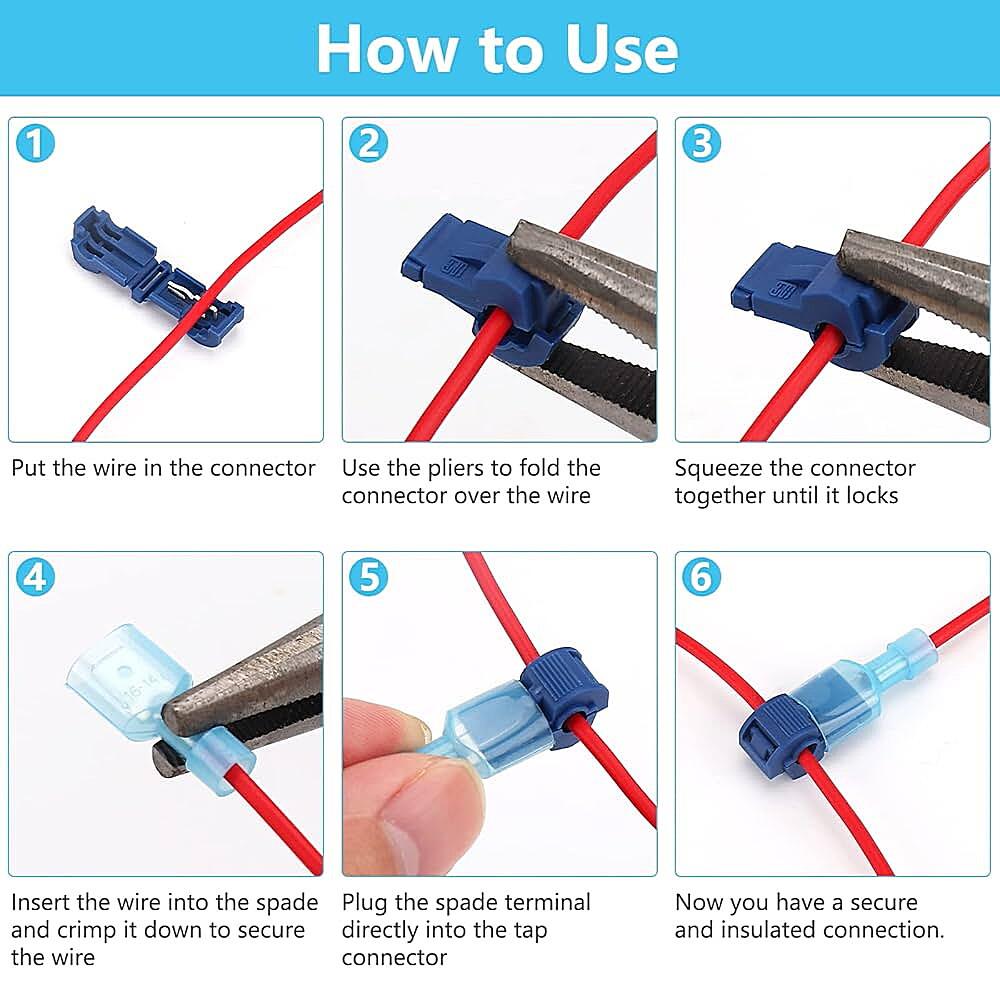

Step-by-Step Guide

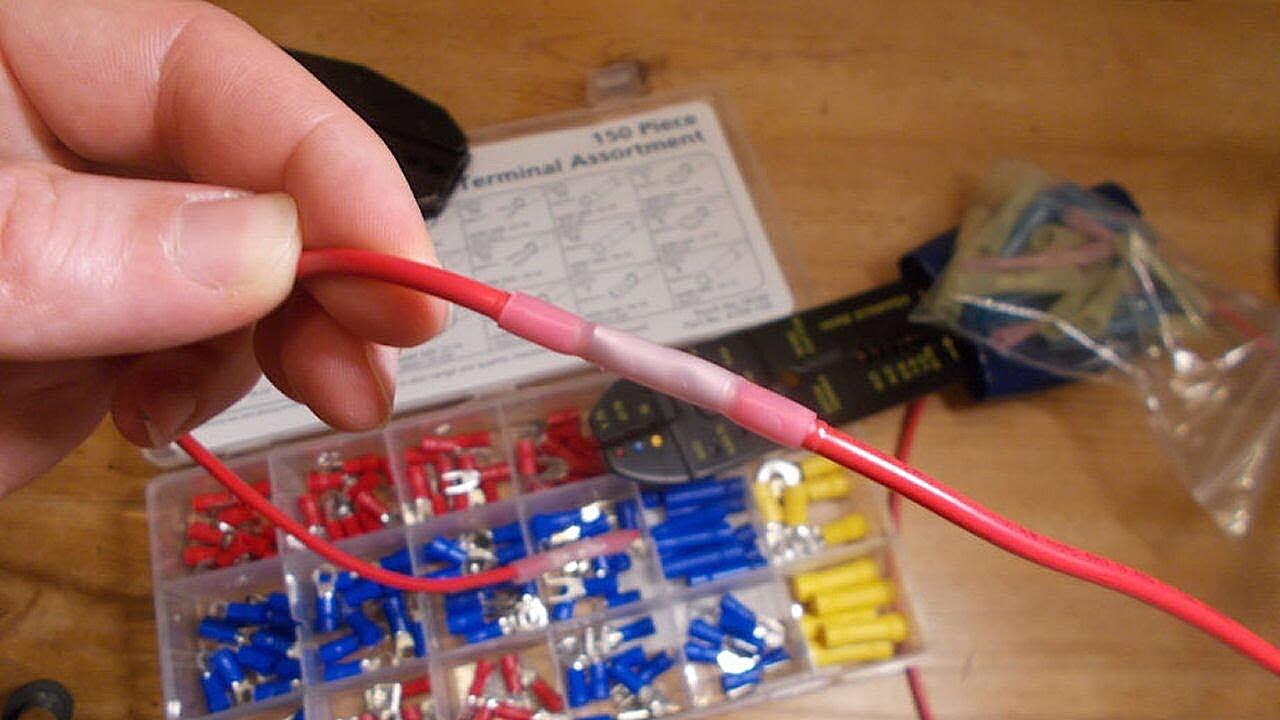

3. The Crimp Connection

Alright, let’s get down to business. Crimp splice connectors are a popular choice for their reliability and ease of use. Here’s a step-by-step guide on how to use them:

Step 1: Strip the Wires. Use a wire stripper to remove about 1/2 inch of insulation from the end of each wire you want to connect. Be careful not to nick or damage the wire itself. Think of it like peeling an orange — you want to remove the peel without damaging the fruit inside.

Step 2: Insert the Wires. Insert the stripped ends of the wires into the crimp connector. Make sure the wires are fully inserted and that the insulation is flush with the end of the connector. This ensures a good, solid connection. Double-check that you are using the appropriate crimp connector size for the gauge of wire you are using.

Step 3: Crimp the Connector. Use a crimping tool to crimp the connector onto the wires. Apply firm, even pressure to create a secure connection. Some crimping tools have different settings for different wire gauges, so be sure to select the correct setting. Its like using a stapler, you apply pressure until it clicks into place!

Step 4: Test the Connection. Give the wires a gentle tug to make sure they’re securely connected. You can also use a multimeter to test the continuity of the connection. A good connection should have a low resistance. Remember, a good connection is like a strong handshake firm and reliable.

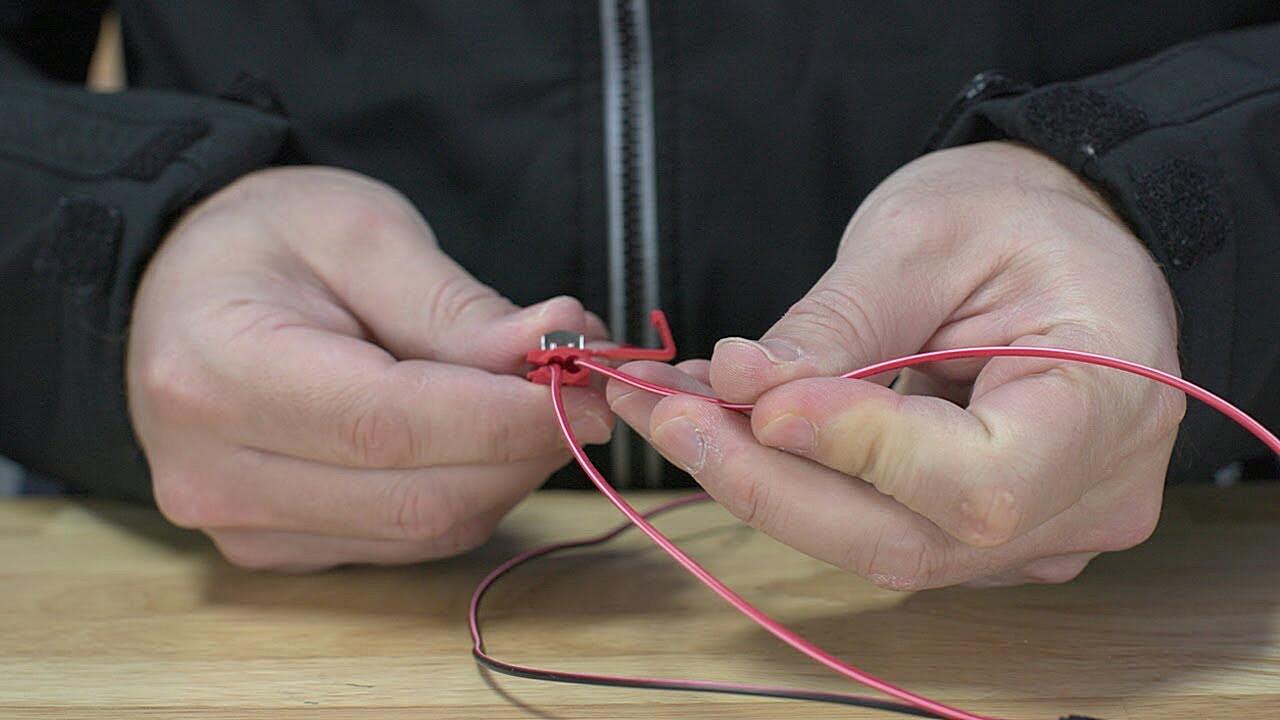

Working with Push-In Splice Connectors

4. Effortless Connections

Push-in splice connectors are incredibly user-friendly, making them a favorite for quick and easy wire connections. They require no tools and can be a real time-saver, especially when dealing with multiple wires. Heres how to use them:

Step 1: Prepare the Wires. Just like with crimp connectors, you’ll need to strip the insulation from the ends of the wires. Aim for about 3/8 to 1/2 inch of exposed wire. A clean, even strip is key for a secure connection. No need for acrobatics, a simple strip will do!

Step 2: Push the Wires In. Simply push the stripped ends of the wires into the designated ports on the connector. Most push-in connectors have a clear housing so you can see that the wire is fully inserted. You should feel a slight click as the wire locks into place. Make sure each wire is snug!

Step 3: Test the Connection. Give each wire a gentle tug to ensure it’s securely held in place. A good push-in connector will grip the wire firmly. If a wire comes loose easily, double-check that it’s fully inserted or consider using a different type of connector. This test is a sanity check!

Optional step: Release and Reuse. Certain push-in connectors are reusable! They feature a lever that allows you to effortlessly release and remove a wire if adjustments are necessary. Its very practical if theres a need for occasional changes or maintenance. This is a lifesaver for the constantly tinkering person!

Safety First

5. Stay Safe, Stay Connected

Working with electricity can be dangerous, so it’s important to take safety precautions whenever you’re using splice connectors. Here are a few essential tips to keep you safe:

Always disconnect the power. Before working on any electrical circuit, always turn off the power at the breaker box. This will prevent accidental shocks. It’s a simple step that can save your life. Treat the breaker box like a sacred item!

Wear safety glasses. Eye protection is essential when working with wires and connectors. Flying debris can cause serious eye injuries. A good pair of safety glasses will keep your eyes safe and sound. Fashionable AND safe. Count us in!

Use insulated tools. When working with electricity, it’s crucial to use tools that are insulated. This will protect you from electric shock if you accidentally come into contact with a live wire. Look for tools that are specifically designed for electrical work. These specialized tools are worth the investment.

Inspect connectors before use. Before using a splice connector, inspect it for any signs of damage, such as cracks or broken parts. A damaged connector may not provide a secure connection and could be a safety hazard. Avoid the drama and inspect everything!