Understanding Load and Resistance Factor Design (LRFD) and Allowable Strength Design (ASD)

1. A Tale of Two Design Philosophies

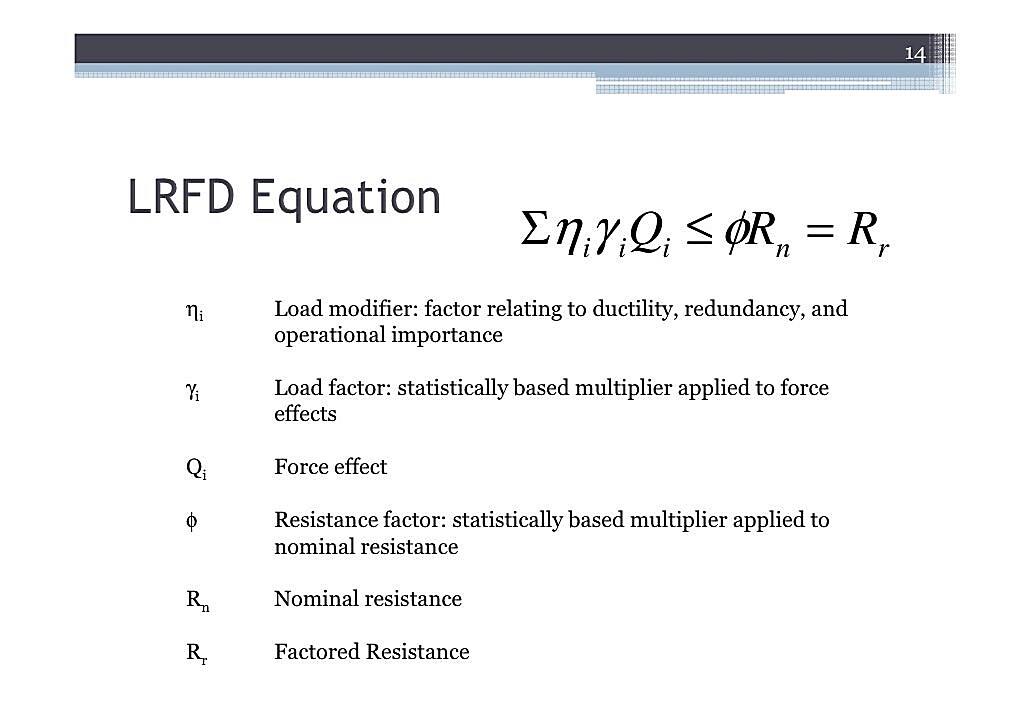

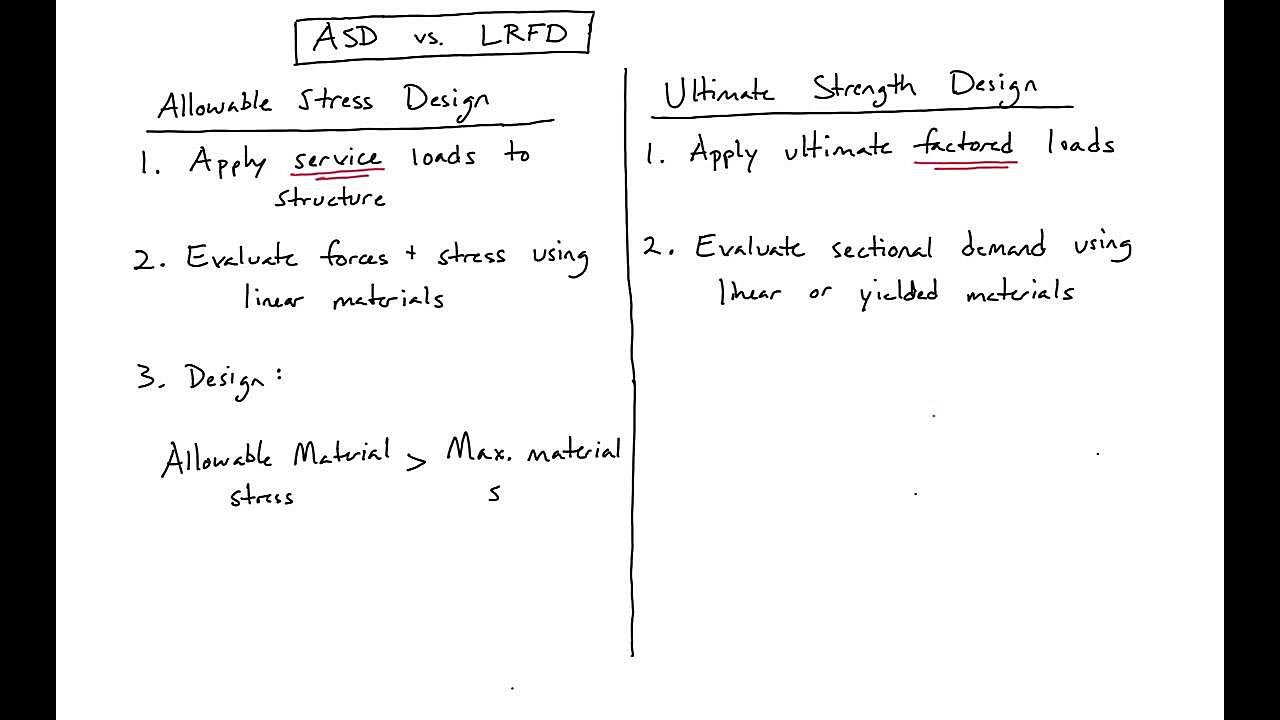

Let’s dive into the world of structural engineering, where decisions about safety and stability are paramount. Two dominant design philosophies reign supreme: Load and Resistance Factor Design (LRFD) and Allowable Strength Design (ASD). Think of them as two different languages spoken by engineers when ensuring a structure can withstand the forces of nature and the demands of human use. LRFD, the younger and arguably more sophisticated language, focuses on probabilities and factored loads, while ASD, the seasoned veteran, relies on safety factors and allowable stresses.

Imagine you’re building a bridge. LRFD would ask: “What’s the worst possible combination of loads this bridge might experience during its lifetime, and how likely is it?” It then applies factors to those loads to amplify them, and factors to the material strength to reduce it, ensuring a very slim chance of failure. ASD, on the other hand, asks: “What’s a reasonable estimate of the loads this bridge will see, and how much stronger does the material need to be than those loads?” It uses a single “factor of safety” to achieve this.

The key difference lies in how uncertainty is handled. LRFD spreads the uncertainty across both the loads and the resistance (strength) of the materials. ASD lumps it all into one big “safety factor,” which can sometimes be overly conservative, especially for situations where loads are well-defined. Think of it like this: LRFD is like a surgeon using precise instruments, while ASD is like a general practitioner using a broad-spectrum antibiotic.

So, why bother knowing about both? Well, many existing structures were designed using ASD, and you might need to evaluate their capacity. Plus, certain applications still benefit from ASD’s simplicity. The bottom line is, understanding both LRFD and ASD gives you a more complete picture of structural design.

Why Convert from LRFD to ASD?

2. When Bridging the Gap Becomes Necessary

Now, why would anyone want to translate from the LRFD language to the ASD language? Several scenarios might call for this conversion. Perhaps you’re evaluating an existing structure designed using LRFD principles but need to assess its capacity using ASD methods for a specific code requirement or a client’s preference. Or maybe you’re comparing the efficiency of designs done using both approaches. It’s kind of like translating a recipe from metric to imperial units — sometimes you just need to speak the same language.

Another common reason arises during the review and approval process. Some building departments, particularly in regions where ASD has a long history, may still be more comfortable reviewing designs presented in ASD format. Converting from LRFD to ASD can facilitate smoother communication and a faster approval timeline. Think of it as using a familiar dialect to avoid misunderstandings.

Furthermore, understanding the relationship between LRFD and ASD can provide valuable insights into the inherent safety margins in a design. By converting from LRFD to ASD, you can directly compare the implied safety factors and assess the relative conservatism of the design. This can be especially useful when evaluating the potential for optimization or identifying areas where the design might be overly cautious. It’s like double-checking your math to ensure you haven’t over-calculated.

Ultimately, the ability to convert between LRFD and ASD is a valuable skill for any structural engineer. It allows for greater flexibility in design and analysis, facilitates communication with stakeholders, and promotes a deeper understanding of structural safety principles. It equips you with the tools to navigate different design contexts and make informed decisions based on the specific needs of the project. Plus, it looks pretty impressive on your resume!

The Conversion Process

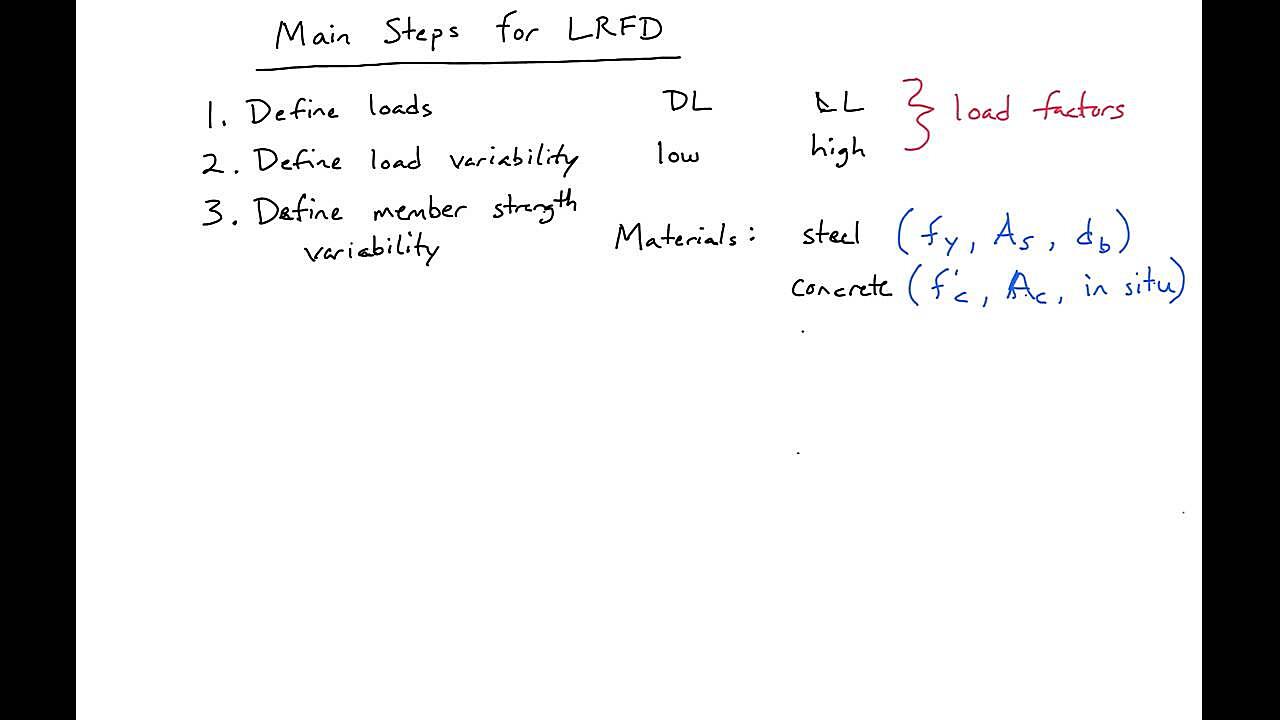

3. Decoding the Language Barrier

Alright, let’s get down to the brass tacks — how do we actually convert from LRFD to ASD? The core idea is to back out the load factors and resistance factors applied in LRFD to arrive at equivalent “allowable” values suitable for ASD. It’s like reverse-engineering a complex equation to find the original ingredients.

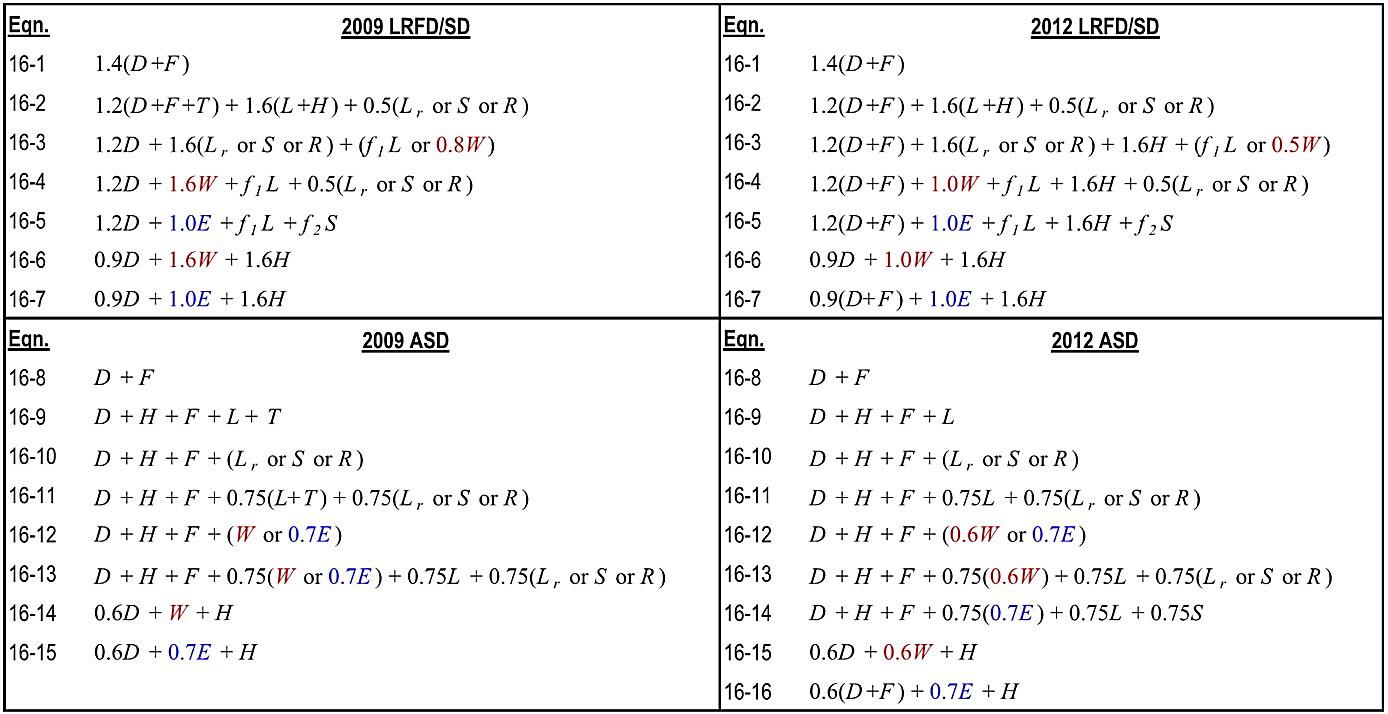

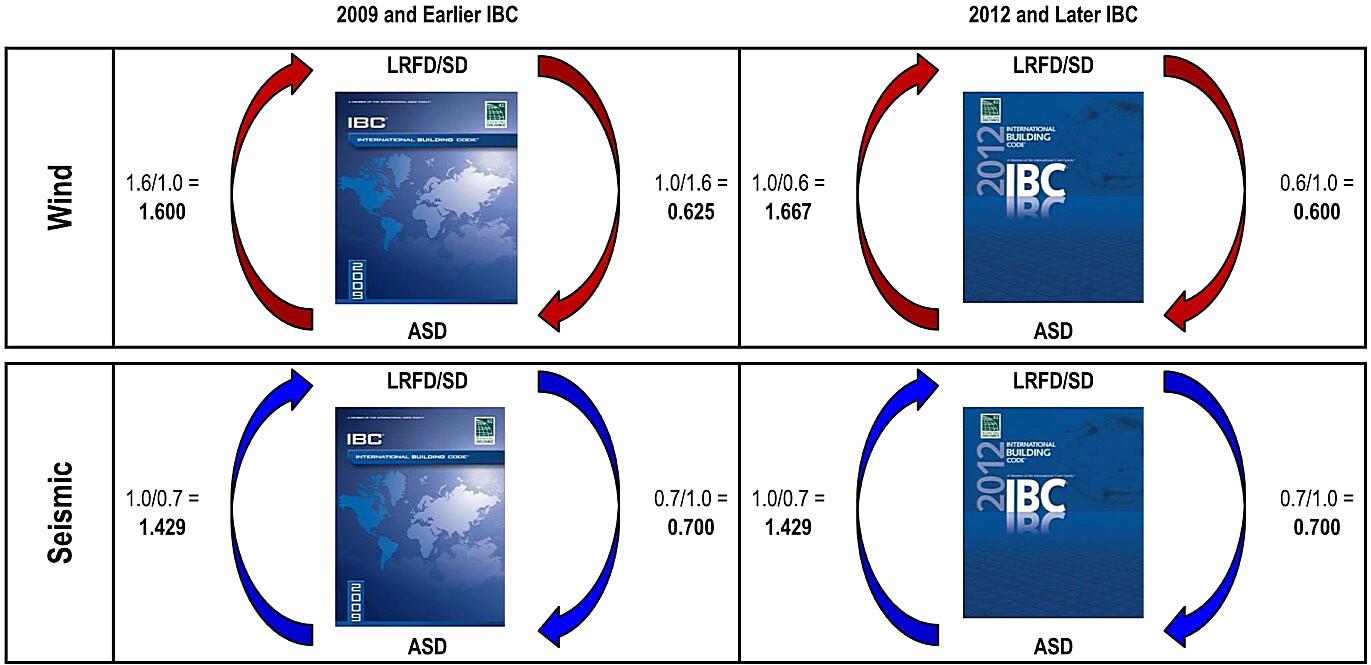

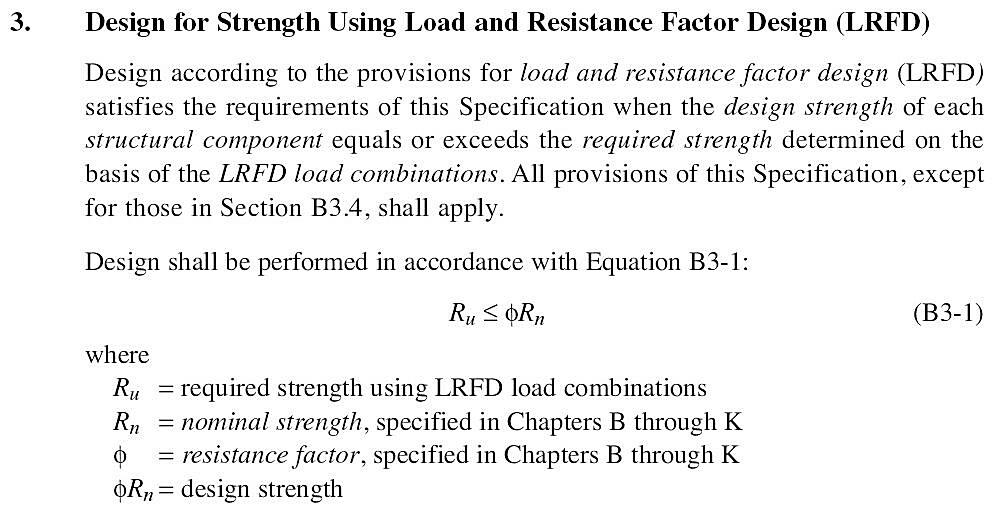

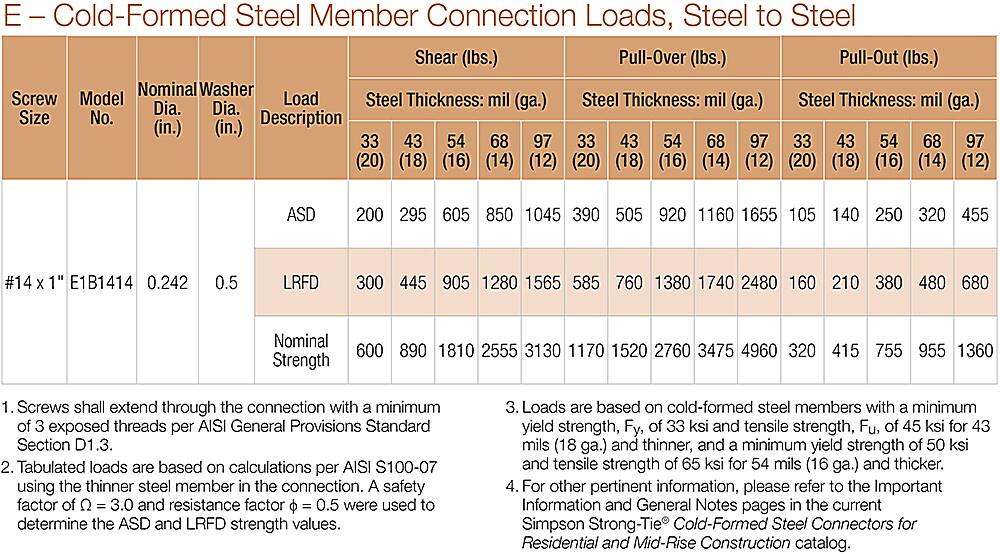

The general approach involves dividing the factored LRFD design strength by a suitable safety factor. This safety factor is typically derived from the load combinations specified in the ASD code and the corresponding load factors used in LRFD. In essence, you’re undoing the amplification of loads and reduction of resistance that LRFD imposes. This is the most confusing part for most people.

For example, consider a simple scenario where you’re checking the flexural capacity of a steel beam. In LRFD, you might have a design strength (Mn) that’s been reduced by a resistance factor (). To convert this to an allowable moment capacity (Ma) for ASD, you would divide Mn by a safety factor (). The appropriate value of depends on the specific load combination being considered. You’re essentially saying, “Okay, LRFD tells me this beam can handle this factored moment. But if I remove the load and resistance factors, what’s the maximum unfactored moment it can safely handle according to ASD?”

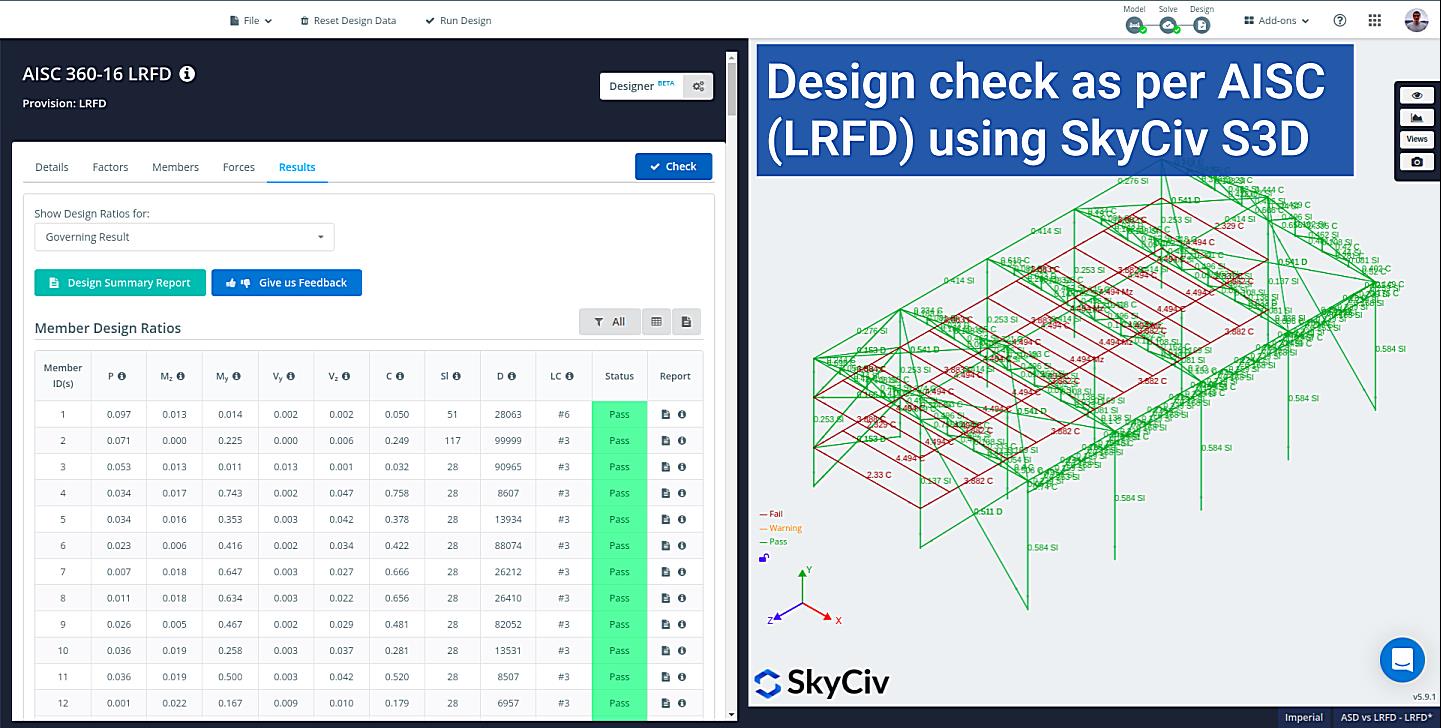

The specific formulas and safety factors will vary depending on the material (steel, concrete, wood, etc.) and the type of load being considered (bending, shear, axial load, etc.). Always refer to the relevant design codes and specifications for the correct conversion factors. It’s not something you want to eyeball. Accuracy is key when it comes to ensuring structural integrity.

Practical Examples and Considerations

4. Putting Theory into Practice

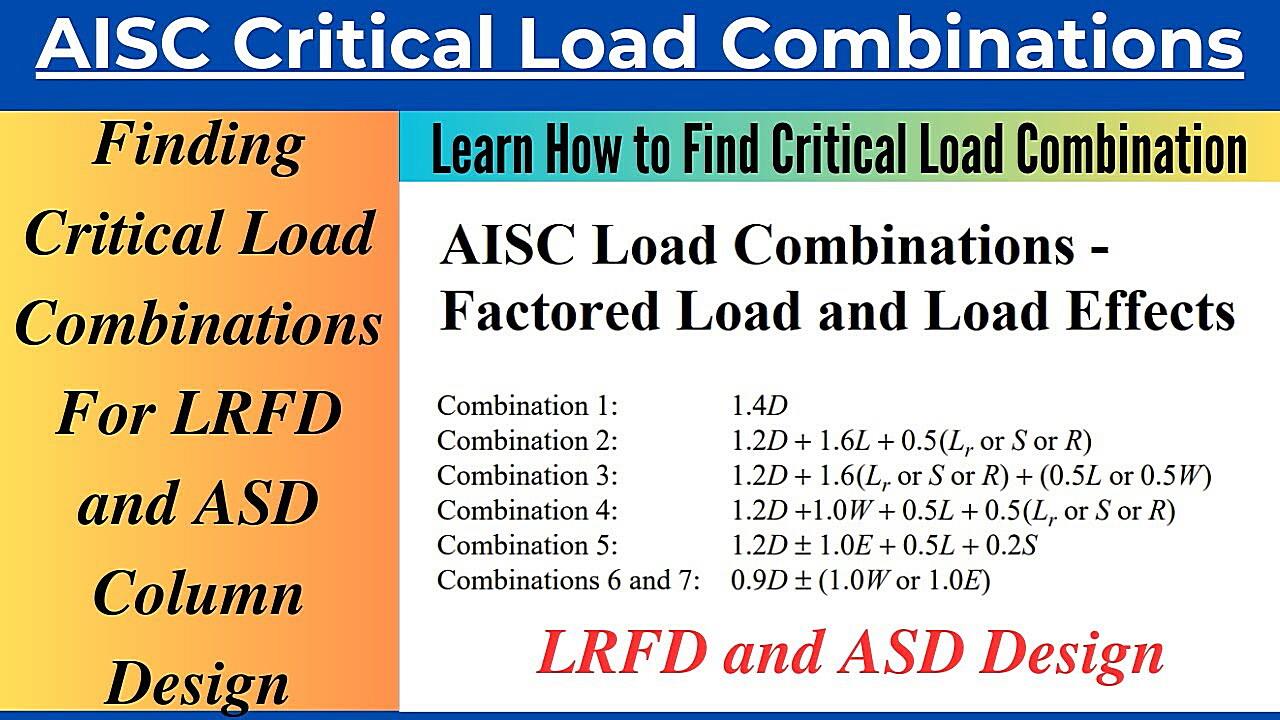

Let’s walk through a simplified example to illustrate the conversion process. Imagine we’ve designed a steel column using LRFD and determined that its factored axial compressive strength (Pn) is 500 kips. We want to find the corresponding allowable axial compressive strength (Pa) for ASD.

According to the AISC (American Institute of Steel Construction) specification, the safety factor for axial compression in ASD is typically around 1.67. Therefore, we would divide the factored LRFD strength by this safety factor: Pa = Pn / = 500 kips / 1.67 299 kips. This means that, according to ASD principles, the column can safely support an axial compressive load of approximately 299 kips.

It’s crucial to remember that this is a simplified example. In real-world scenarios, you’ll need to consider multiple load combinations and the corresponding safety factors for each combination. Also, the conversion process can become more complex for members subjected to combined loading (e.g., axial load and bending moment). In such cases, you may need to use interaction equations to ensure that the allowable stresses are not exceeded.

Additionally, pay close attention to the specific requirements of the governing design code. Different codes may have slightly different load factors, resistance factors, and safety factors. Always consult the relevant code provisions to ensure that your conversion is accurate and compliant. Remember, accuracy and compliance are non-negotiable in structural engineering. Cut corners elsewhere — just not here.

Common Pitfalls and How to Avoid Them

5. Steering Clear of Design Disasters

Converting from LRFD to ASD might seem straightforward, but there are a few common pitfalls to watch out for. One frequent mistake is using the wrong safety factor. As mentioned earlier, the appropriate safety factor depends on the specific load combination and the type of load being considered. Using an incorrect safety factor can lead to significant errors in your calculations and potentially compromise the safety of the structure.

Another common error is neglecting to consider the effects of load duration. Some materials, such as wood, exhibit different strength characteristics depending on the duration of the applied load. For example, a wood member can typically withstand a higher load for a short period of time than it can for a long period of time. When converting from LRFD to ASD for wood structures, it’s essential to account for these load duration effects.

A further mistake lies in forgetting that the underlying assumptions of LRFD and ASD are different. LRFD is based on probabilistic principles, while ASD is based on deterministic principles. This means that the safety factors used in ASD are intended to account for all sources of uncertainty, including variations in material properties, construction tolerances, and load estimations. When converting from LRFD to ASD, it’s essential to ensure that you’re adequately accounting for these uncertainties.

To avoid these pitfalls, always double-check your calculations, consult the relevant design codes and specifications, and seek guidance from experienced engineers when needed. It’s better to be cautious and thorough than to make a mistake that could have serious consequences. Remember, structural engineering is not a game of chance. It’s a profession that demands precision, attention to detail, and a commitment to safety.