You May Also Like :

Understanding Total Flow

1. Why Knowing Your Total Flow Matters

Ever wondered how much “stuff” is moving through a pipe, a river, or even your air conditioning system? That’s total flow in a nutshell! Knowing this measurement is seriously important in a bunch of different fields, from making sure your city has enough water to keeping chemical reactions in a factory humming along smoothly. It’s not just about knowing if something’s flowing, but how much is flowing, and that difference is key for efficiency, safety, and even regulatory compliance. Think of it like baking a cake — you can’t just eyeball the ingredients; you need precise measurements for everything to turn out right. Measuring total flow is much the same!

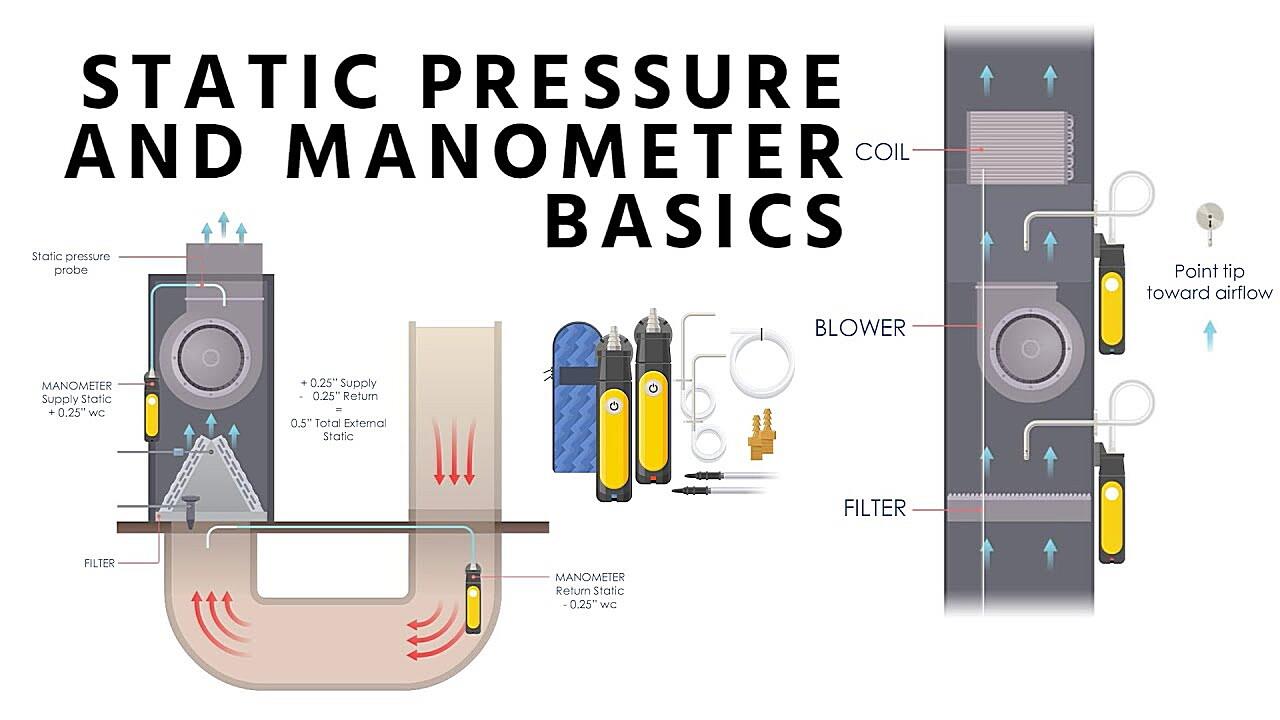

But why is it so vital? Well, imagine trying to manage a water treatment plant without knowing how much water is coming in. Chaos, right? Similarly, in industries like oil and gas, inaccurate flow measurements can lead to significant financial losses, not to mention potential environmental hazards. And in HVAC systems, understanding air flow is critical for energy efficiency and maintaining comfortable indoor environments. Basically, if you’re dealing with fluids or gases moving from point A to point B, knowing your total flow is non-negotiable. And trust me, getting it wrong can be a real headache (and potentially quite costly!).

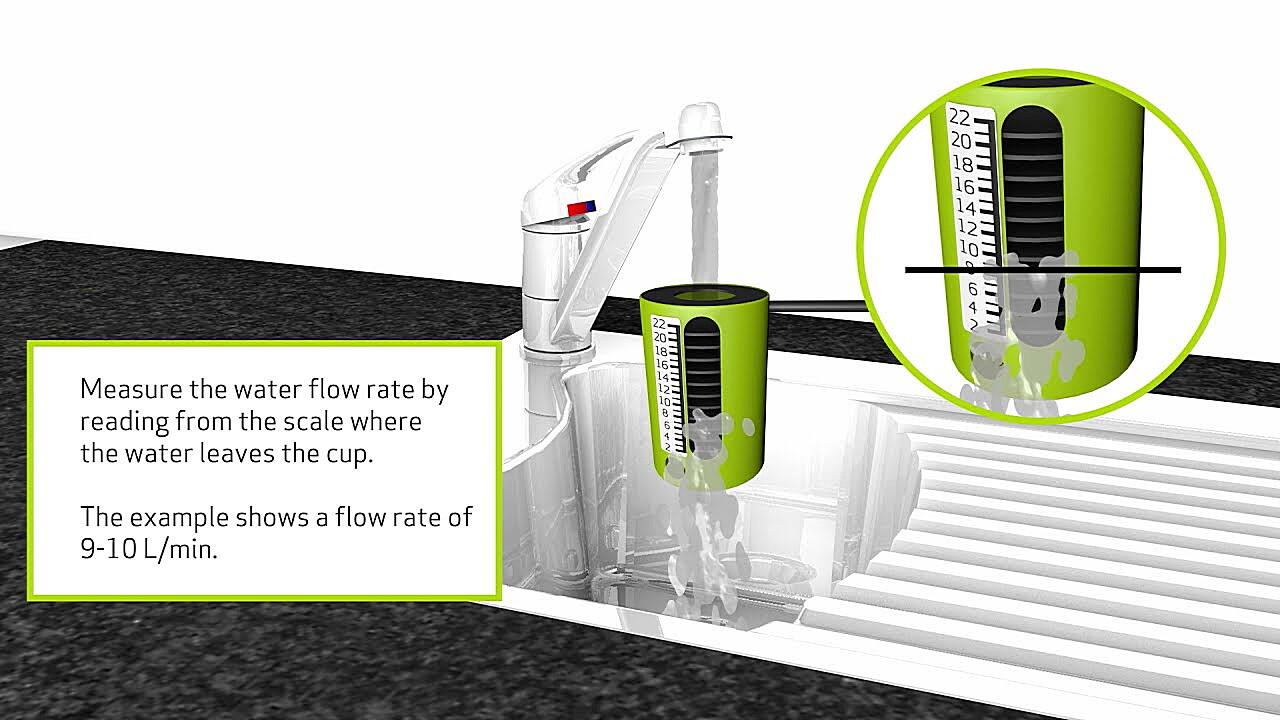

We’re not just talking about big industrial applications, either. Even something as simple as calibrating your home’s sprinkler system relies on understanding flow rates. Making sure each zone gets the right amount of water prevents overwatering (wasting water and money) and underwatering (leading to a sad, dry lawn). So, whether you’re a seasoned engineer or a homeowner trying to keep your grass green, grasping the basics of total flow measurement is a useful skill. It empowers you to make informed decisions and solve practical problems.

So, lets get down to brass tacks. Measuring total flow isn’t some mystical art; it’s a science with well-established techniques and tools. And while the specifics might vary depending on what you’re measuring and where, the underlying principles are surprisingly straightforward. Don’t worry; we’ll break it all down in plain English, no fancy jargon required! We will explore different methods, discuss their pros and cons, and help you choose the right approach for your specific needs. Get ready to become a total flow measuring maestro!

Common Methods for Measuring Total Flow

2. Choosing the Right Tool for the Job

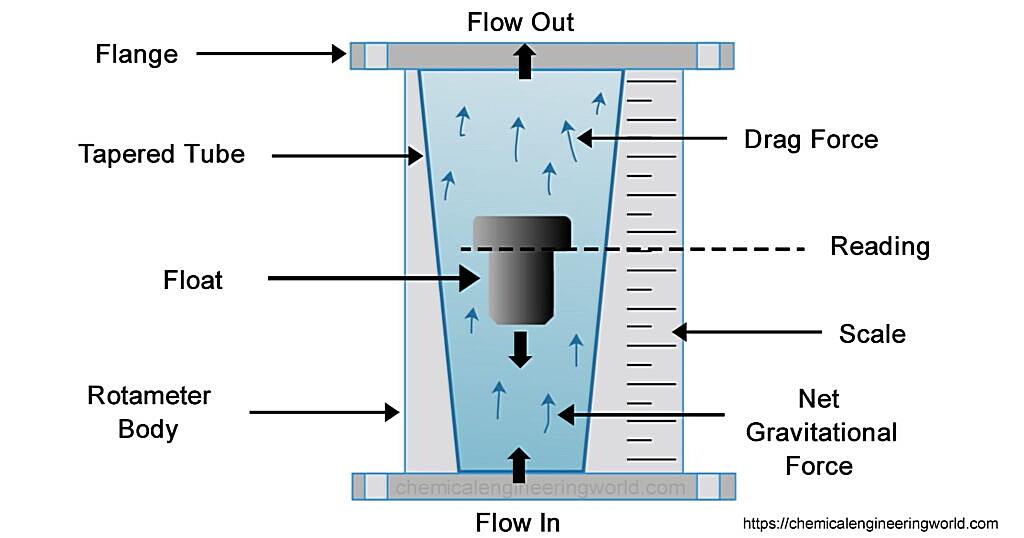

Okay, so you’re on board with the importance of measuring total flow. Now, let’s talk about how to actually do it. There’s a surprisingly wide array of methods available, each with its own strengths and weaknesses. Choosing the right one depends on factors like the type of fluid or gas you’re measuring, the size of the pipe or channel, the level of accuracy you need, and, of course, your budget. It’s like picking the right wrench for the job — you wouldn’t use a monkey wrench to tighten a tiny screw, would you?

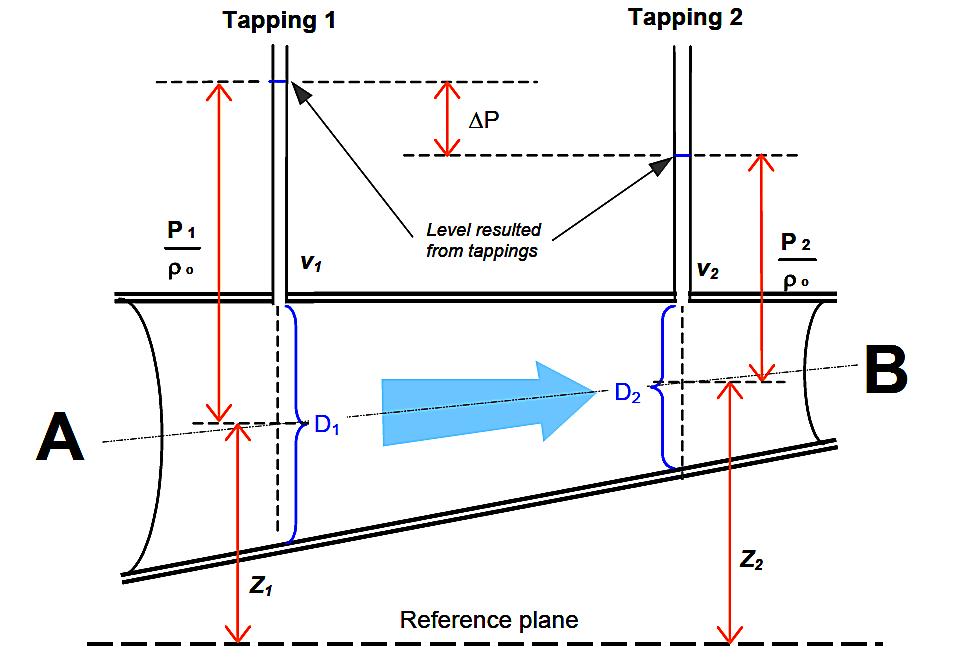

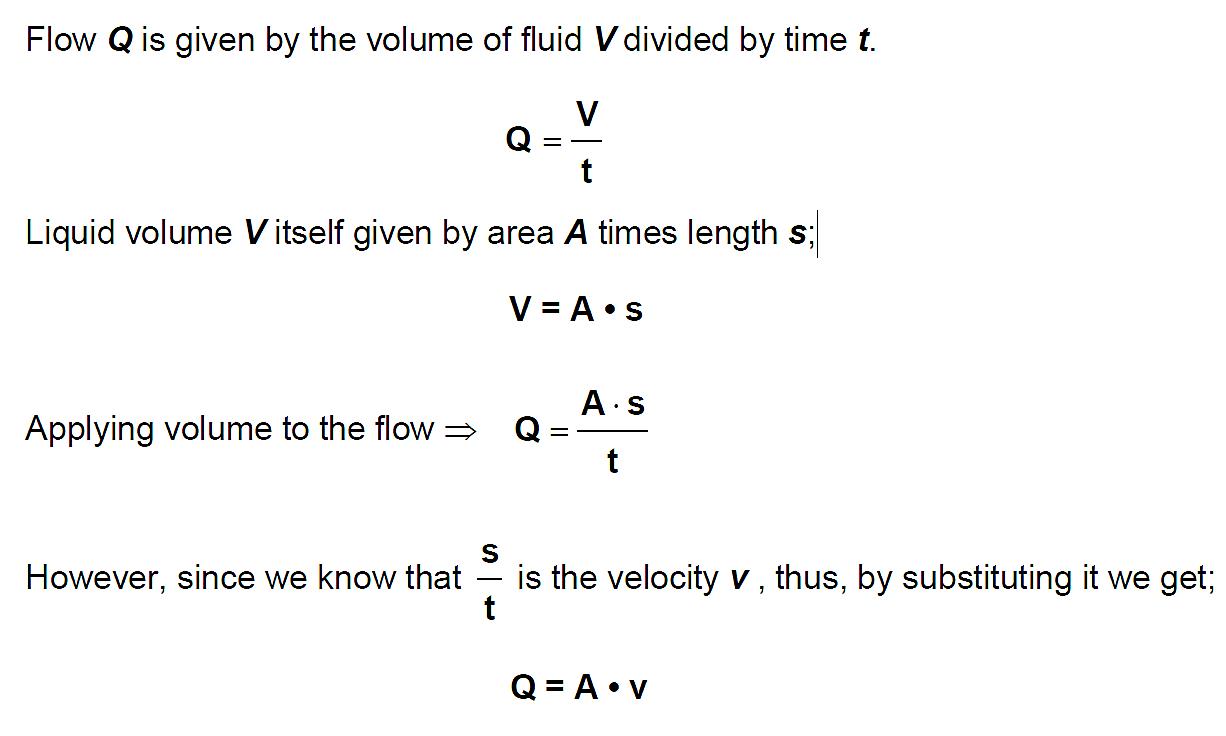

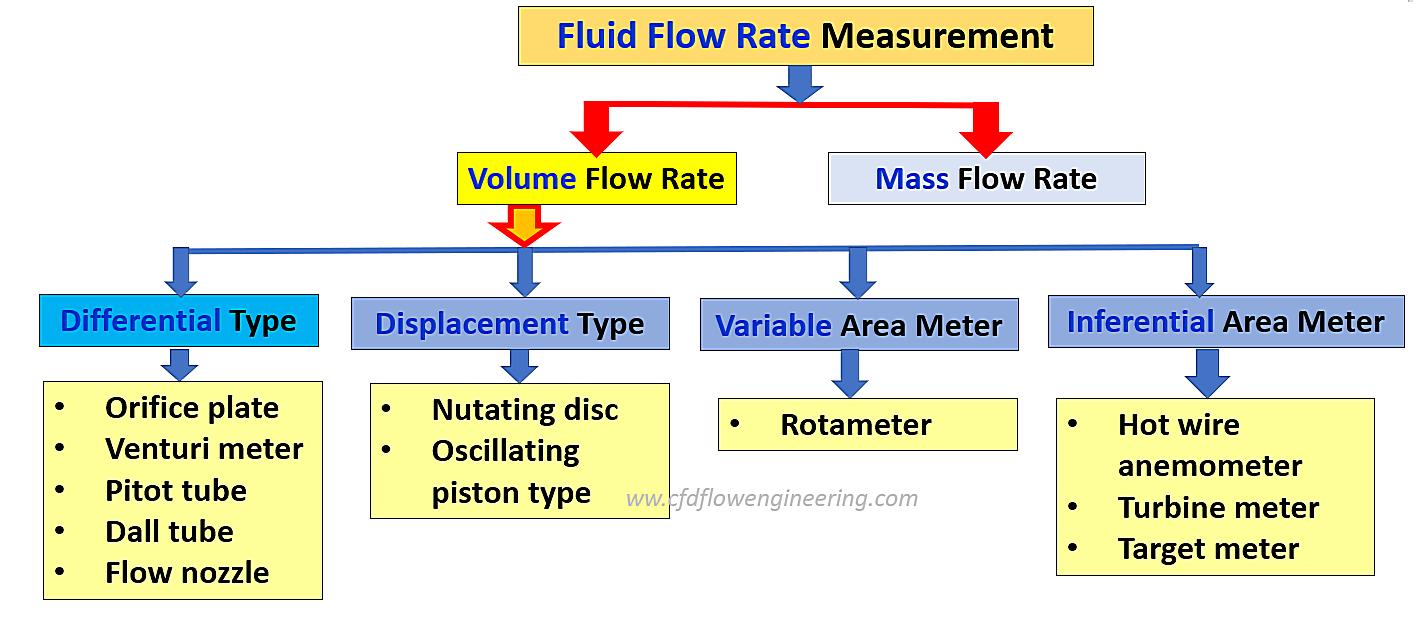

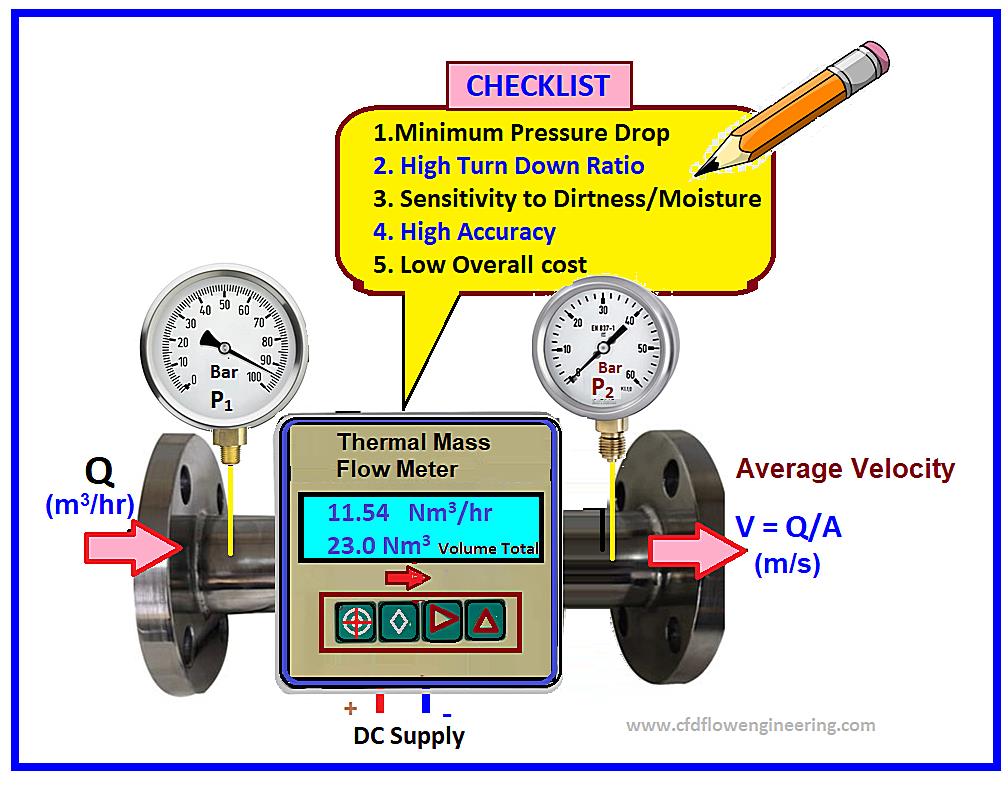

One popular method involves using differential pressure flow meters. These ingenious devices create a constriction in the flow path, causing a pressure drop. The amount of pressure drop is directly related to the flow rate, allowing you to calculate the total flow. Think of it like squeezing a garden hose — the tighter you squeeze, the faster the water squirts out. Orifice plates, venturi tubes, and flow nozzles are all examples of differential pressure flow meters. They are relatively simple and cost-effective, making them a good choice for many applications.

Then there are velocity flow meters, which measure the speed of the fluid or gas directly. These include turbine meters, paddlewheel meters, and electromagnetic flow meters. Turbine meters, for instance, have a rotating turbine that spins at a rate proportional to the flow velocity. Electromagnetic flow meters, on the other hand, use magnetic fields to measure the velocity of conductive fluids. These meters are generally more accurate than differential pressure meters but can also be more expensive and require more maintenance. Imagine a little propeller spinning faster when the current’s strong, thats a turbine meter at its heart.

Finally, we have positive displacement flow meters. These meters physically trap a known volume of fluid or gas and count the number of times the trap is filled and emptied. They are incredibly accurate and are often used for custody transfer applications, where precise measurement is crucial (like selling gasoline at a gas station). Think of it like a tiny bucket that fills up, dumps its contents, and counts each dump. These are robust and accurate, but usually pricier and can sometimes impede flow.

Delving Deeper

3. Getting Specific with Measurement Techniques

So, we’ve touched on the main types of flow meters, but let’s get a little more specific. Understanding the nuances of each type will help you make a more informed decision when choosing the right one for your application. After all, you wouldn’t want to use a hammer to screw in a lightbulb, right? (Okay, maybe you wouldn’t do that, but you get the idea!). Getting the wrong flow meter is similar — it just won’t work effectively.

Orifice plates, a type of differential pressure meter, are essentially flat plates with a precisely sized hole in the middle. They’re simple, inexpensive, and widely used, especially in applications where accuracy is not paramount. However, they can cause a significant pressure drop and are prone to clogging if the fluid is dirty. Think of it like a traffic bottleneck: it’s simple and cheap to implement, but it slows everything down.

Venturi tubes are also differential pressure meters, but they’re designed to minimize pressure loss compared to orifice plates. They have a converging section that accelerates the fluid, followed by a diverging section that allows it to recover its pressure. This makes them a better choice for applications where pressure drop is a concern. They’re like a streamlined bottleneck — still slows things down a bit, but not as much.

Turbine meters use a rotating turbine to measure the flow velocity. They’re accurate and reliable, but they can be sensitive to fluid viscosity and require regular maintenance to keep the turbine spinning freely. These work well when liquids flow smoothly and consistently.

Electromagnetic flow meters, also known as magmeters, use a magnetic field to measure the velocity of conductive fluids. They have no moving parts, which makes them durable and low-maintenance. However, they only work with conductive fluids, like water with dissolved salts. Think of it like magic — it only works with certain ingredients (conductive fluids, in this case).

Factors Affecting Flow Measurement Accuracy

4. Avoiding Common Pitfalls

Even with the best flow meter in the world, you can still end up with inaccurate measurements if you’re not careful. Several factors can affect accuracy, and it’s important to be aware of them so you can take steps to mitigate their impact. Think of it like aiming a bow and arrow — even if you have a great bow, you still need to account for wind, distance, and your own steadiness to hit the target. Flow measurement is similar: external factors can throw off your readings if you’re not paying attention.

One major factor is fluid properties. The density, viscosity, and temperature of the fluid can all affect the performance of a flow meter. For example, if the viscosity of the fluid changes, it can affect the pressure drop across a differential pressure meter or the speed of a turbine meter. It’s like trying to pour honey versus water — they behave differently and require different approaches.

Installation effects can also play a significant role. The flow profile upstream of the meter should be fully developed, meaning it should be uniform and free from swirls or turbulence. Straight pipe runs are typically required upstream of the meter to allow the flow to develop properly. Bends, valves, and other obstructions can disrupt the flow profile and lead to inaccurate measurements. Think of it like a river — if it’s flowing smoothly in a straight line, it’s easier to measure its velocity than if it’s swirling around rocks.

Calibration is another critical factor. Flow meters should be calibrated regularly to ensure that they’re providing accurate readings. Calibration involves comparing the meter’s output to a known standard and adjusting it if necessary. It’s like tuning a musical instrument — you need to check it regularly to make sure it’s playing the right notes. Without proper calibration, your measurements could be way off.

Finally, maintenance is essential for ensuring long-term accuracy. Flow meters should be inspected regularly for signs of wear and tear, and any necessary repairs should be made promptly. Clogged lines, damaged sensors, and worn bearings can all affect the meter’s performance. It’s like taking care of your car — regular oil changes and tune-ups will keep it running smoothly for years to come.

Practical Applications and FAQs

5. Real-World Examples and Your Burning Questions Answered

Okay, so we’ve covered the theory and the techniques. Now, let’s bring it all together with some real-world examples and address some frequently asked questions. After all, knowledge is power, but applied knowledge is even more powerful! Knowing how to measure total flow is great, but understanding where and why it’s used makes it even more valuable.

Think about a brewery, for instance. They need to precisely measure the flow of water, beer, and other ingredients at various stages of the brewing process. Too much or too little of something could ruin an entire batch! Or consider a pharmaceutical company. They need to carefully control the flow of chemicals during drug manufacturing to ensure product quality and safety. Even something as seemingly mundane as managing a swimming pool relies on accurate flow measurement to ensure proper chlorination and filtration.

Beyond these specific examples, total flow measurement is crucial for optimizing energy consumption, reducing waste, and improving overall efficiency in countless industries. It’s also essential for environmental monitoring, helping us track and manage water resources, reduce pollution, and protect our planet. So, whether you’re a brewer, a pharmacist, an environmental scientist, or just someone who cares about sustainability, understanding total flow measurement is a valuable asset.

6. Frequently Asked Questions (FAQs)

Q: What’s the difference between flow rate and total flow?

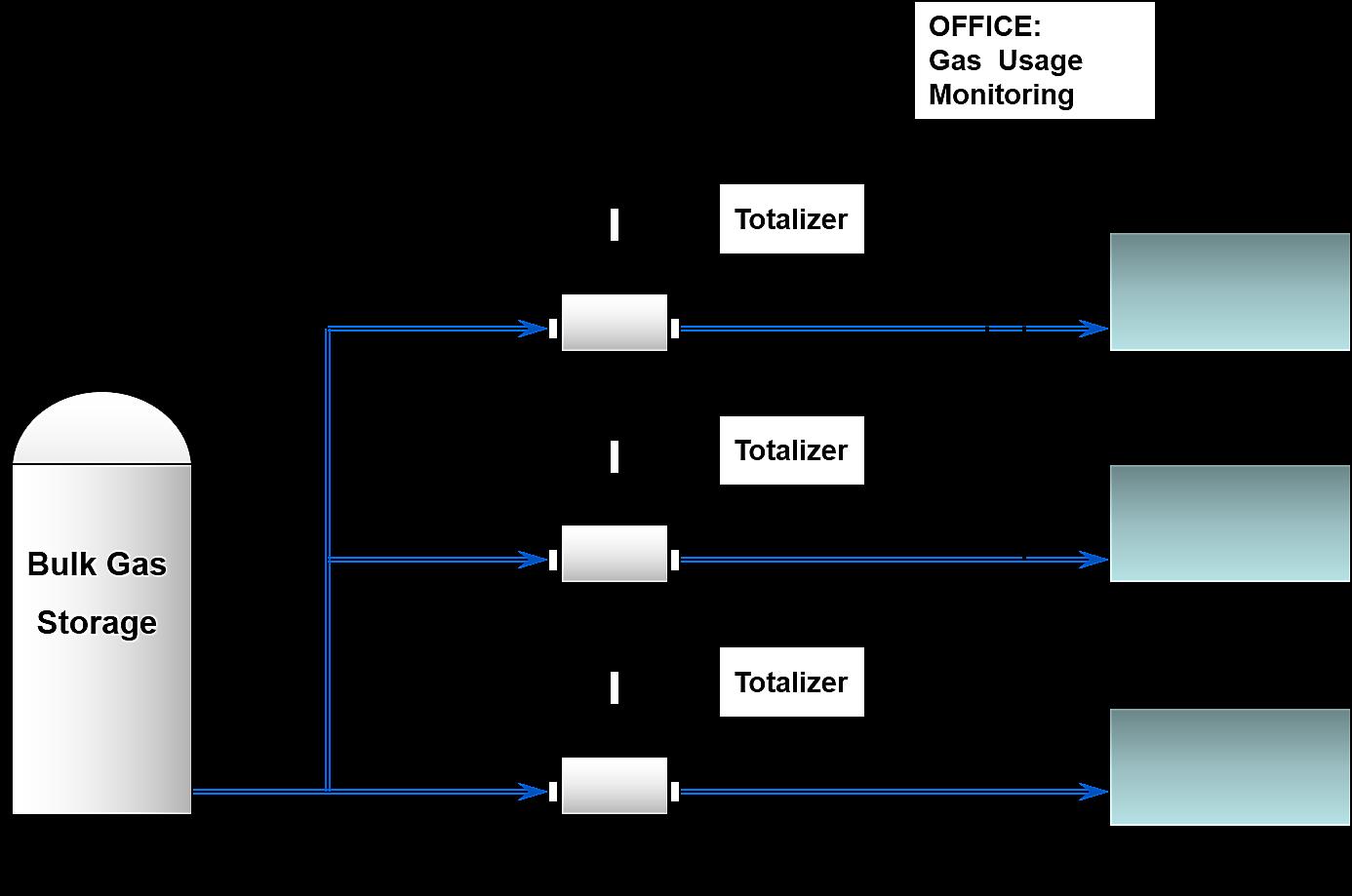

A: Flow rate is the amount of fluid or gas that passes a point per unit of time (e.g., gallons per minute). Total flow is the cumulative amount of fluid or gas that has passed a point over a longer period (e.g., total gallons used in a day). Think of flow rate as the speed of a car, and total flow as the total distance traveled.

Q: How often should I calibrate my flow meter?

A: The frequency of calibration depends on the application and the type of flow meter. As a general rule, flow meters should be calibrated at least once a year, but more frequent calibration may be required for critical applications. Always refer to the manufacturer’s recommendations for specific calibration intervals.

Q: Can I use the same flow meter for different fluids?

A: It depends on the type of flow meter and the properties of the fluids. Some flow meters are designed to work with a wide range of fluids, while others are more specific. It’s important to consult the manufacturer’s specifications to ensure that the flow meter is compatible with the fluid you’re measuring.