You May Also Like :

Feeling the Twist

1. Understanding the Force

Ever wondered how you can tell just how tightly something is screwed on? Or maybe you’re tinkering with an engine and need to make sure you’re hitting the right specifications. That, my friend, is where torque comes in. Torque, in simple terms, is a twisting force that tends to cause rotation. And while fancy digital torque wrenches exist, sometimes you just need to do it the old-fashioned way. Let’s dive into measuring torque manually, shall we?

Imagine trying to open a stubborn jar. You’re applying a force to the lid, trying to rotate it. That’s torque in action! The amount of torque depends on how much force you’re applying and how far from the center of the lid your hand is. The further away, the more leverage you have, and the easier it is to twist that darn lid open. It’s the same principle when tightening a bolt, turning a wrench, or even pedaling a bicycle.

Why bother measuring torque at all? Well, over-tightening can damage parts, strip threads, or even cause components to fail. Under-tightening, on the other hand, can lead to things coming loose, which can be dangerous, especially in machinery or vehicles. So, getting the torque just right is super important for safety and reliability.

So, ditch the assumption that you need expensive tools to get a decent measurement. With some ingenuity and a bit of physics knowledge, you can get a pretty good idea of the torque you’re applying, even without all the bells and whistles.

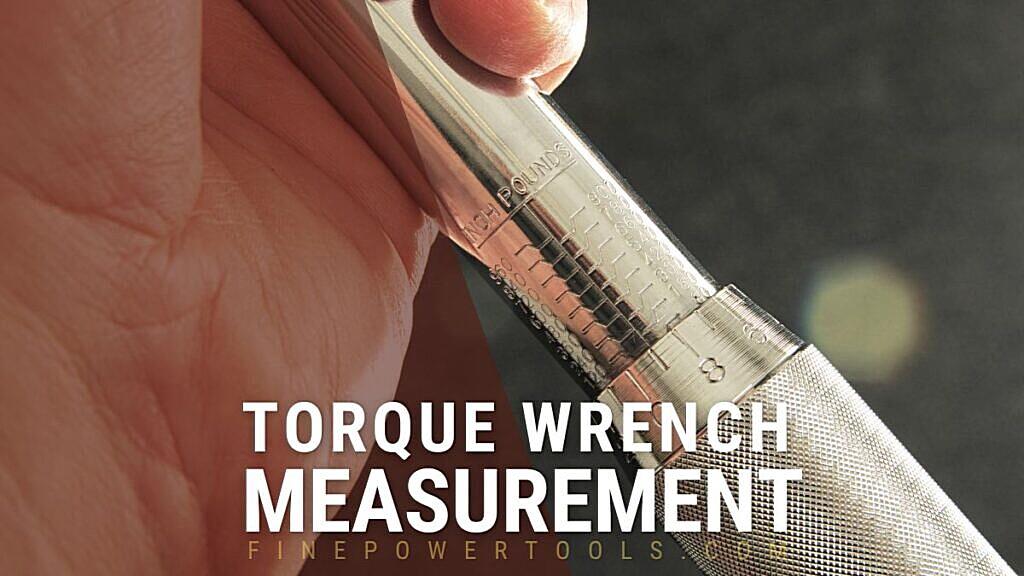

2. The Classic Torque Wrench

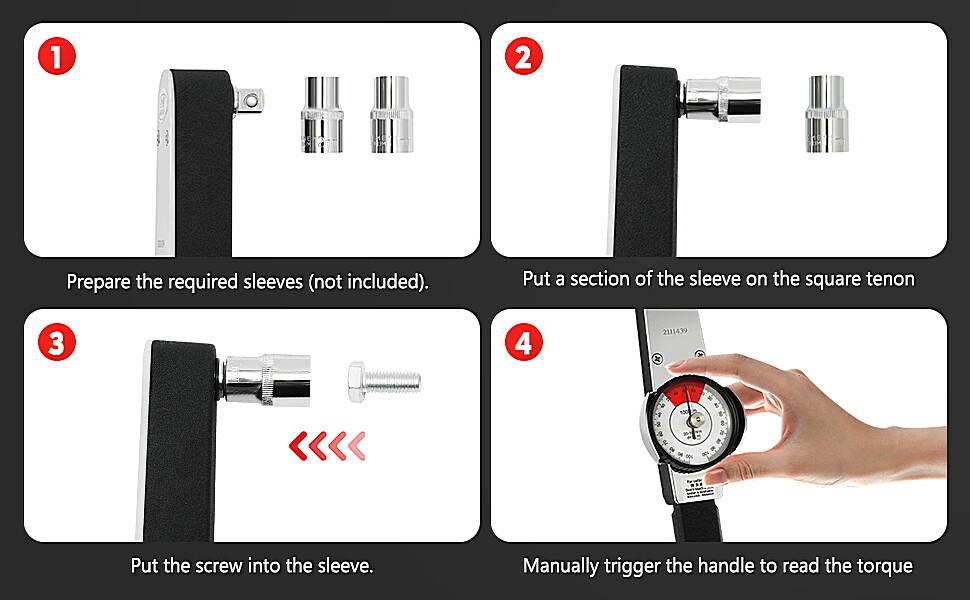

Alright, let’s talk about the most common manual tool for measuring torque: the torque wrench. Now, even within the realm of torque wrenches, there are different types. The most basic, and often most affordable, is the beam-style torque wrench. It’s a simple design, usually consisting of a long handle with a pointer and a scale that indicates the torque being applied.

Using a beam-style torque wrench is pretty straightforward. You attach the socket to the nut or bolt you want to tighten. Then, you apply force to the handle, watching the pointer move along the scale. When the pointer reaches the desired torque value, you stop applying force. Simple as that! The beauty of the beam-style wrench is its simplicity and relative affordability. Its a great option for someone who only needs to measure torque occasionally.

Another type of manual torque wrench is the click-type torque wrench. These wrenches are a bit more sophisticated. You set the desired torque value on the handle, and when you reach that value, the wrench makes a distinct “click” sound, letting you know you’ve achieved the correct torque. This type is really handy because you don’t have to constantly watch the scale while you’re tightening.

Click-type torque wrenches offer increased precision, but they do require calibration to ensure accurate readings. Over time, the internal mechanism can drift, so it’s a good idea to get them professionally calibrated periodically. Beam-style wrenches, on the other hand, are less prone to calibration issues due to their simpler design.

3. Leverage and Length

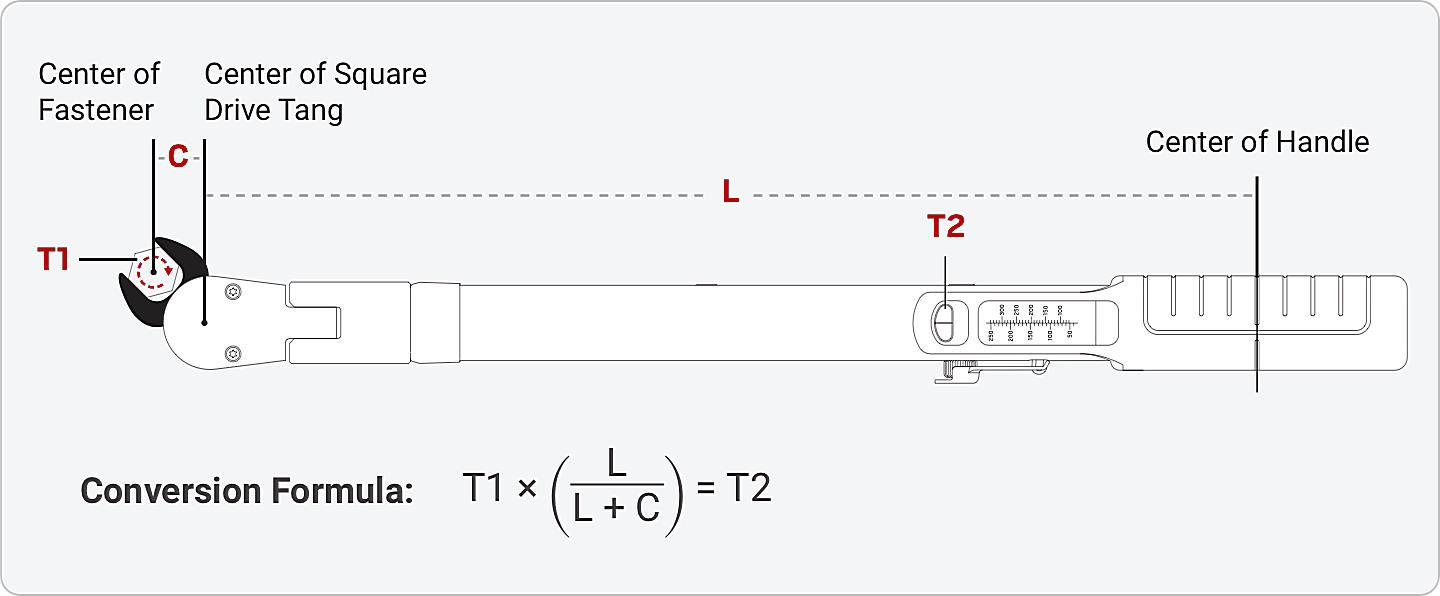

Okay, so you don’t have a torque wrench. Don’t panic! You can still get a decent estimate of torque manually, especially if you know the force you’re applying and the length of the lever (e.g., the wrench handle). Remember that torque is force multiplied by distance. So, if you can measure those two things, you can calculate the torque.

Let’s say you’re using a wrench that’s one foot long (that’s 12 inches). If you’re pulling on the end of the wrench with a force of 50 pounds, the torque you’re applying is 50 foot-pounds (or 600 inch-pounds). Of course, this method relies on accurately estimating the force you’re applying. This can be tricky, but you can use a bathroom scale to get a better idea of how much force you’re exerting.

To use a bathroom scale, place the wrench on the nut or bolt you want to tighten. Then, position the scale so that it’s directly under the point where you’ll be applying force. As you pull on the wrench, read the force on the scale. Multiply that force by the length of the wrench to get an estimate of the torque. Keep in mind that this method isn’t as accurate as using a torque wrench, but it can be useful in a pinch.

This “improvised” method really shines when you need a ballpark figure and don’t have dedicated tools available. Remember, safety first! Always be careful when applying force, and make sure you have a good grip to avoid slips or injuries. Knowing the basics of leverage and force can be surprisingly useful in a variety of situations.

4. Calibrating Your Senses

Sometimes, you might find yourself in a situation where you have no tools at all—no torque wrench, no bathroom scale, nothing! In these cases, you have to rely on your experience and judgment to get the torque “close enough.” This is often referred to as the “feel” method. Now, I’m not advocating for relying solely on feel, especially in critical applications, but it can be a useful skill in a pinch.

The “feel” method involves developing a sense of how much force is required to tighten a particular fastener. This comes with experience, and it’s important to start by tightening fasteners to the correct torque using a torque wrench to get a baseline. Over time, you’ll start to develop a feel for how tight things should be.

For example, you might notice that a particular bolt feels snug when it’s tightened to a certain point, and then it starts to feel much tighter as you apply more force. This is where experience comes in. You’ll learn to recognize the point where the bolt is properly tightened without over-tightening it. This is definitely a skill that takes practice and a good understanding of mechanical principles.

The danger of relying solely on “feel” is the high potential for error. Factors like thread condition, lubrication, and material type can all affect how tight a fastener feels. So, while the “feel” method can be a useful skill to have, it should always be used with caution, and whenever possible, you should verify the torque using a torque wrench or other measuring device.

5. Important Considerations and Safety Tips

No matter which method you use to measure torque manually, there are a few important considerations to keep in mind. First, always make sure you’re using the correct units. Torque is typically measured in foot-pounds (ft-lbs) or inch-pounds (in-lbs). It’s easy to mix these up, so pay close attention!

Second, be aware of the limitations of manual torque measurement. Manual methods are not as accurate as using a calibrated electronic torque wrench. If you need precise torque measurements, especially in critical applications, it’s best to invest in a good quality torque wrench and have it calibrated regularly. For general applications, however, manual methods can be perfectly adequate.

Finally, always prioritize safety. Wear appropriate safety gear, such as gloves and eye protection. Make sure you have a good grip on the wrench to avoid slips, and never apply more force than you can comfortably control. Over-tightening can damage parts and cause injuries, so always be cautious and use common sense.

Measuring torque manually is a valuable skill that can save you time, money, and frustration. Whether you’re using a beam-style torque wrench, calculating torque based on force and distance, or relying on your “feel,” understanding the principles of torque and practicing safe techniques will help you get the job done right.

FAQ

6. Frequently Asked Questions

Got questions about measuring torque? You’re not alone! Here are a few common questions, answered for your convenience.

7. What’s the difference between torque and horsepower?

Torque is a twisting force that causes rotation. Horsepower, on the other hand, is a measure of how quickly work can be done. Think of torque as the “grunt” that gets things moving, and horsepower as the “speed” at which they move. Torque is what gets a car moving from a stop, while horsepower is what allows it to maintain high speeds.

8. How often should I calibrate my torque wrench?

It depends on how often you use it, but a good rule of thumb is to calibrate your torque wrench at least once a year, or more often if you use it frequently. Click-type torque wrenches are more prone to calibration drift than beam-style wrenches. If you’re using a torque wrench for critical applications, it’s best to err on the side of caution and calibrate it more frequently.

9. Can I use a regular wrench instead of a torque wrench?

Yes, you can, but it’s generally not recommended, especially for critical applications where precise torque is required. A regular wrench doesn’t give you any indication of the torque you’re applying, so it’s easy to over- or under-tighten fasteners. If you must use a regular wrench, be very careful and use your best judgment, but always use a torque wrench whenever possible.

10. What happens if I overtighten a bolt?

Overtightening a bolt can damage the threads of the bolt and the material it’s threaded into. This can weaken the joint and potentially lead to failure. In some cases, overtightening can even cause the bolt to break. That’s why it’s so important to use the correct torque specifications and to measure torque accurately.