Understanding ACB Breaking Capacity

1. What Exactly Is ACB Breaking Capacity, Anyway?

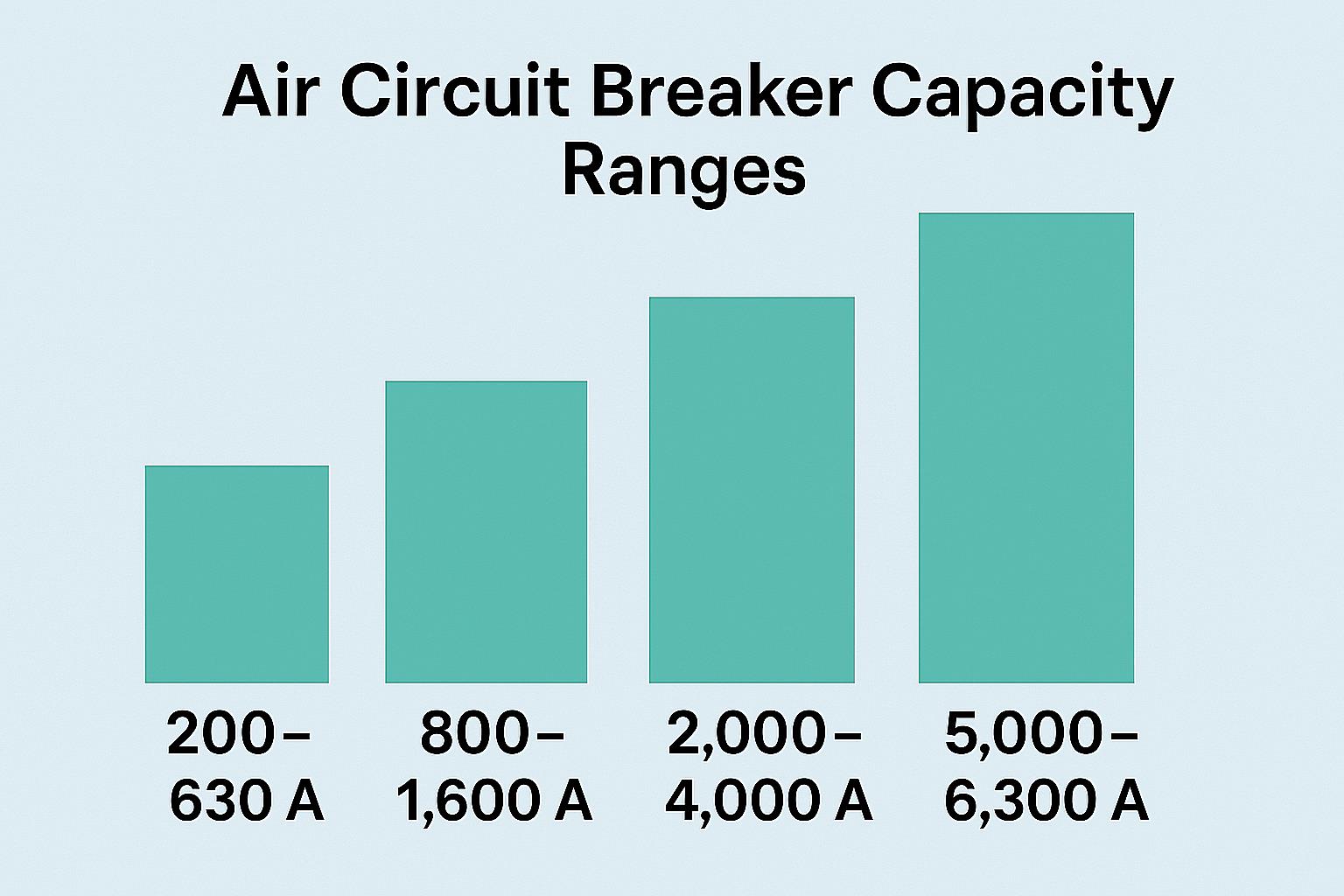

Alright, let’s talk Air Circuit Breakers (ACBs). These aren’t your everyday light switch heroes; they’re the big guns in electrical protection, designed to safeguard your systems from overcurrents and short circuits. Now, “breaking capacity” — that’s the keyword here — is essentially an ACB’s superpower. It’s the maximum fault current an ACB can safely interrupt without, you know, exploding or turning into a pile of molten metal. Think of it like a superhero’s ability to deflect an energy blast without disintegrating. Its a crucial specification to ensure electrical safety. Get it wrong, and you’re potentially playing with fire (literally!).

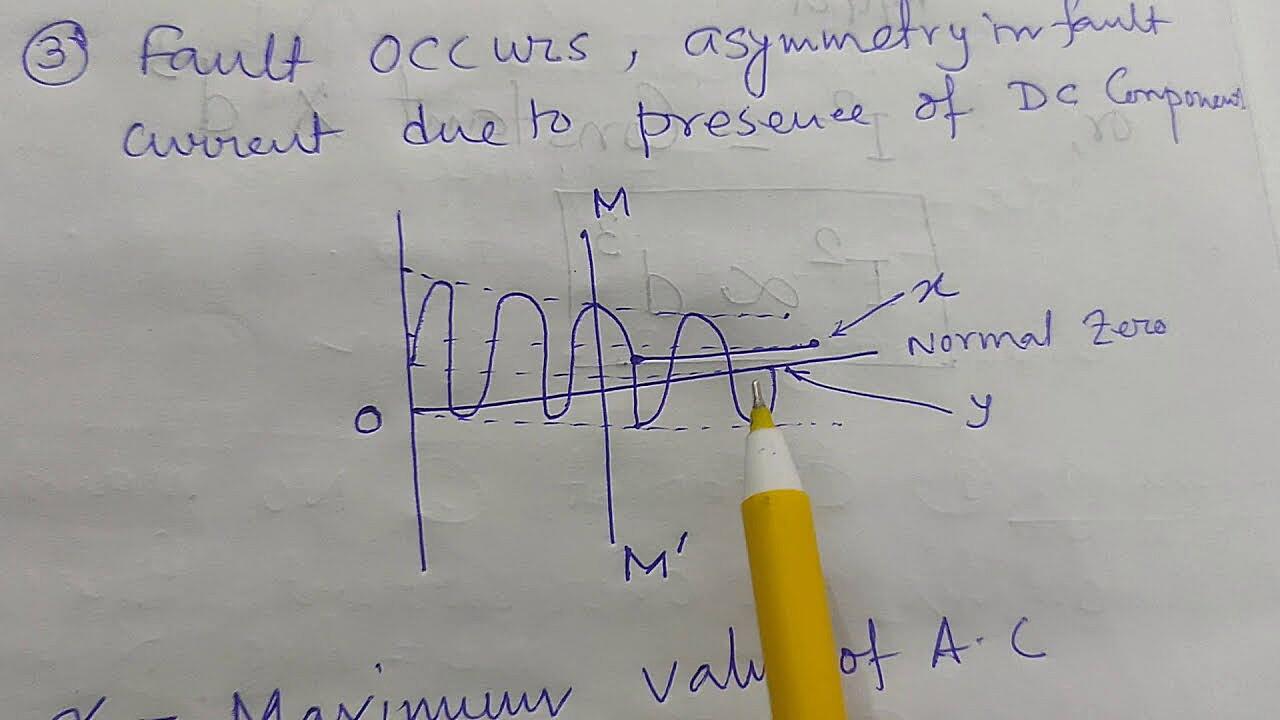

Breaking capacity is usually expressed in kA (kiloamperes), indicating the RMS (Root Mean Square) value of the symmetrical fault current the breaker can handle. So, if you see an ACB with a breaking capacity of 50kA, it means it’s designed to interrupt a fault current of up to 50,000 amps without any catastrophic consequences. It’s not just about stopping the current; it’s about doing it safely and reliably, time after time. Underestimating this value can lead to equipment damage, system downtime, and, in worst-case scenarios, serious injuries.

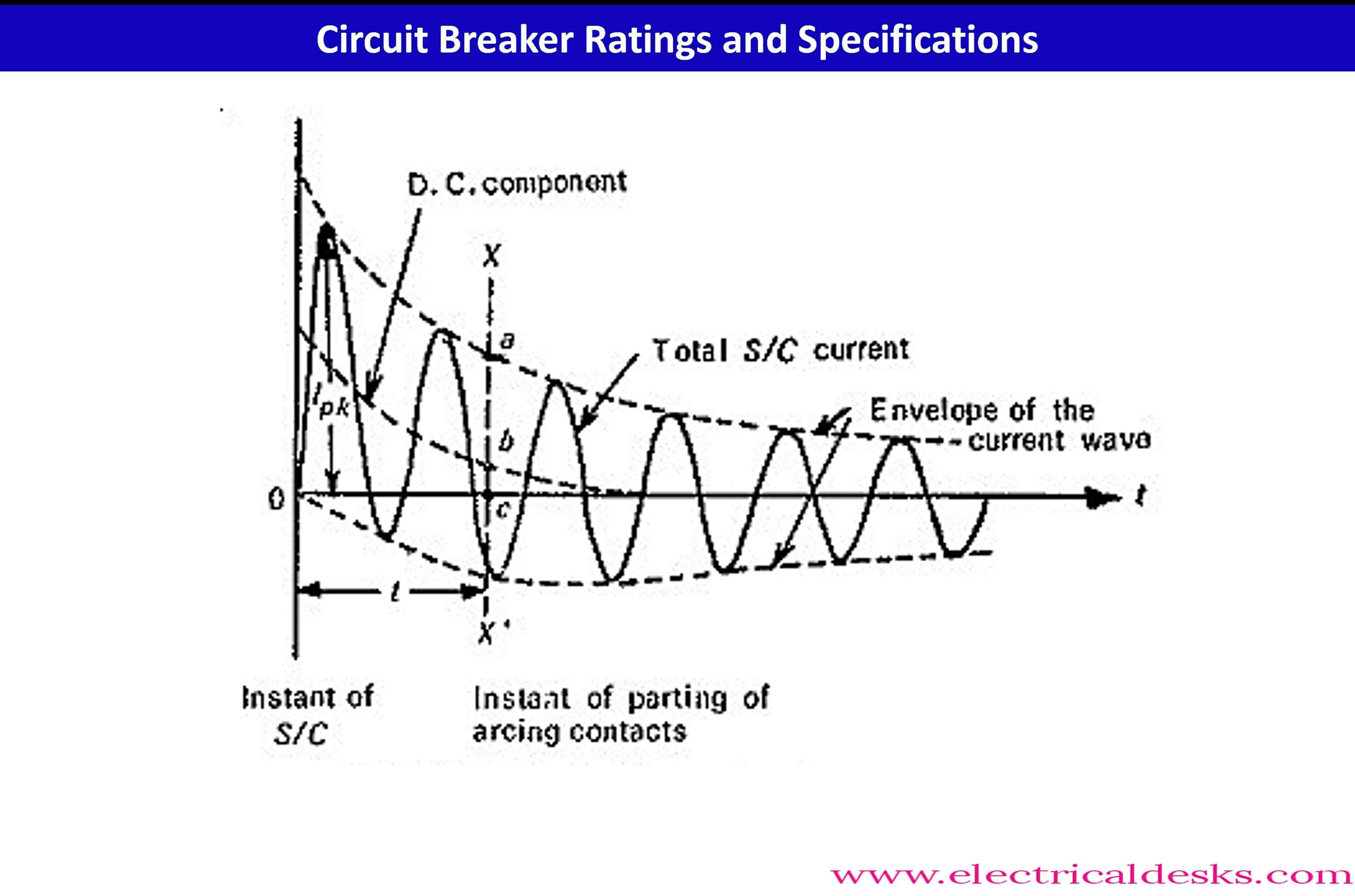

Why is this so important? Imagine a sudden short circuit occurs. The current surges to enormous levels in fractions of a second. The ACB’s job is to detect this surge and rapidly open its contacts to cut off the flow of electricity. If the fault current exceeds the ACB’s breaking capacity, the breaker might fail to interrupt the current properly. This can result in arcing, overheating, and even the breaker itself being damaged beyond repair. Its like trying to stop a speeding train with a bicycle not a pretty sight.

So, the next time you see an ACB, remember that its breaking capacity is more than just a random number. It’s a critical safety parameter that determines its ability to protect your electrical system from potentially devastating fault currents. It’s the silent guardian, always ready to spring into action when things go wrong. This isn’t just about preventing inconvenience; it’s about safeguarding lives and property.

The Formula

2. Deconstructing the Calculation

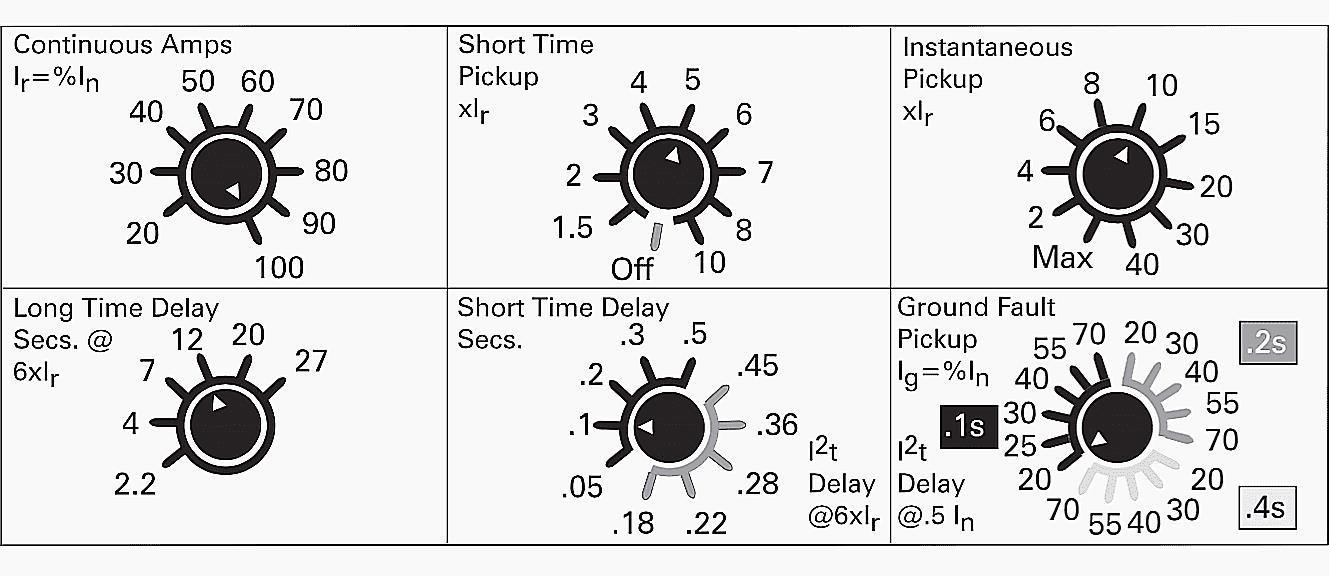

Okay, let’s get into the math! While the actual testing and certification of breaking capacity is done in a lab with specialized equipment, we can understand the principles involved. There isn’t a single, universally applicable formula to calculate breaking capacity from scratch in a theoretical sense. The breaking capacity is primarily determined through rigorous testing according to international standards like IEC 60947-2 or UL 489. These standards dictate the test circuits, voltage levels, current levels, and operating sequences required to certify an ACB’s breaking capacity. That being said, we can explore the factors that influence it and what data is used in assessing a breakers suitability for a particular application. The factors include Voltage, impedance and fault current.

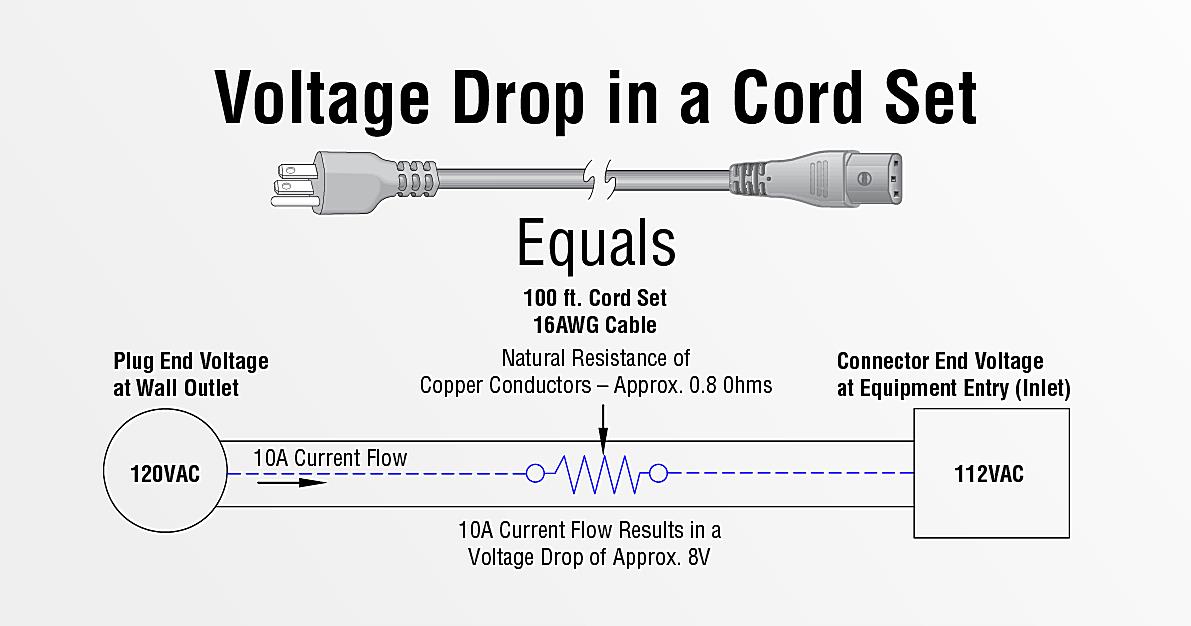

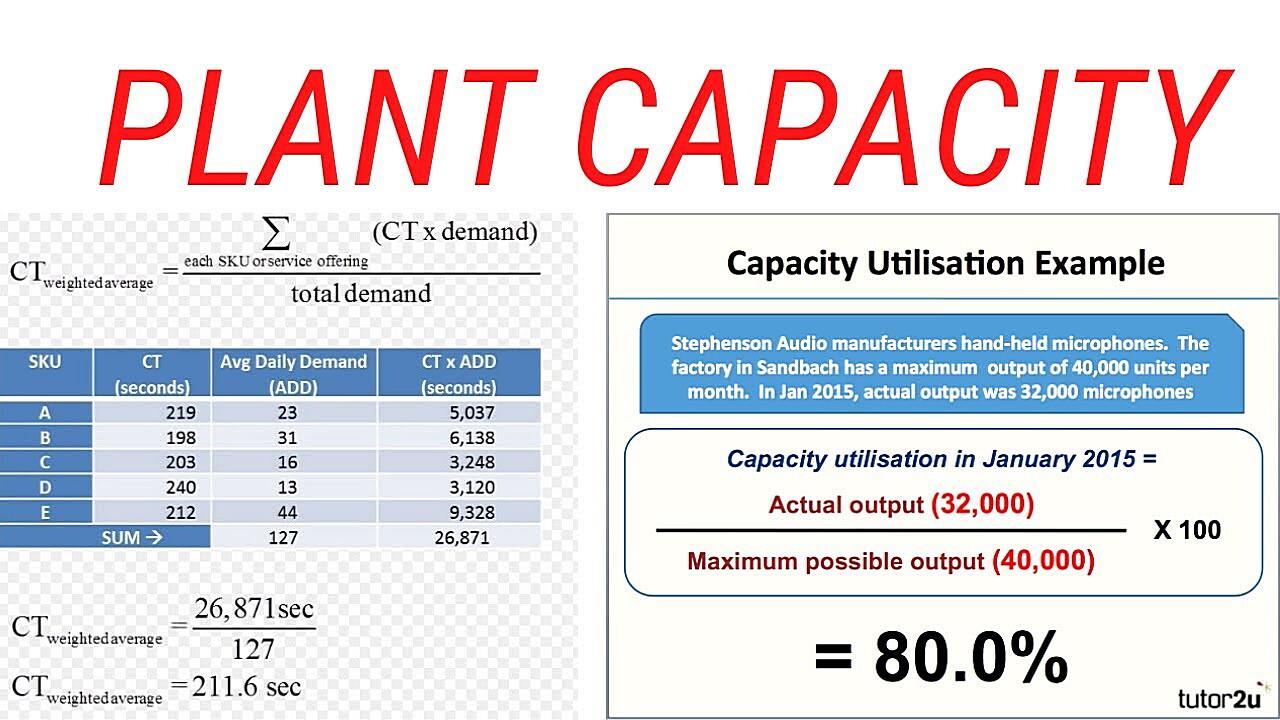

First and foremost, you need to determine the prospective fault current at the point where the ACB will be installed. This is the maximum current that could flow during a short circuit. This involves calculating the impedance of the entire upstream circuit, including transformers, cables, and any other components. The lower the impedance, the higher the prospective fault current. You’ll typically need to obtain impedance values from manufacturer datasheets or conduct on-site measurements. Also, consider the system voltage. The higher the voltage, the greater the potential stress on the ACB during a fault. Higher system voltages generally necessitate ACBs with higher breaking capacities.

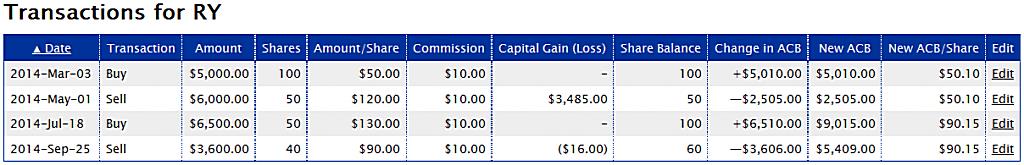

Once you know the prospective fault current, you need to ensure that the ACB’s rated breaking capacity (Icu) is greater than or equal to this value. Icu is the ultimate breaking capacity, which is the highest fault current the ACB can interrupt without being damaged. However, it may not be able to interrupt the fault current multiple times at this level. There’s also Ics, the service breaking capacity, which is the fault current the ACB can interrupt multiple times and still maintain its functionality. Ics is usually a percentage of Icu (e.g., 50%, 75%, or 100%).

Beyond just comparing the fault current to Icu, you should consider the application and required reliability. If the ACB is in a critical application where downtime is unacceptable, you might choose a breaker with a significantly higher breaking capacity than the calculated fault current. This provides a margin of safety and reduces the risk of the breaker failing during a fault. Its always better to be over-prepared than under-prepared when dealing with electrical safety. Remember to consult with a qualified electrical engineer for accurate fault current calculations and ACB selection. They have the expertise to consider all relevant factors and ensure a safe and reliable electrical system.

Factors That Influence ACB Breaking Capacity

3. Delving Deeper

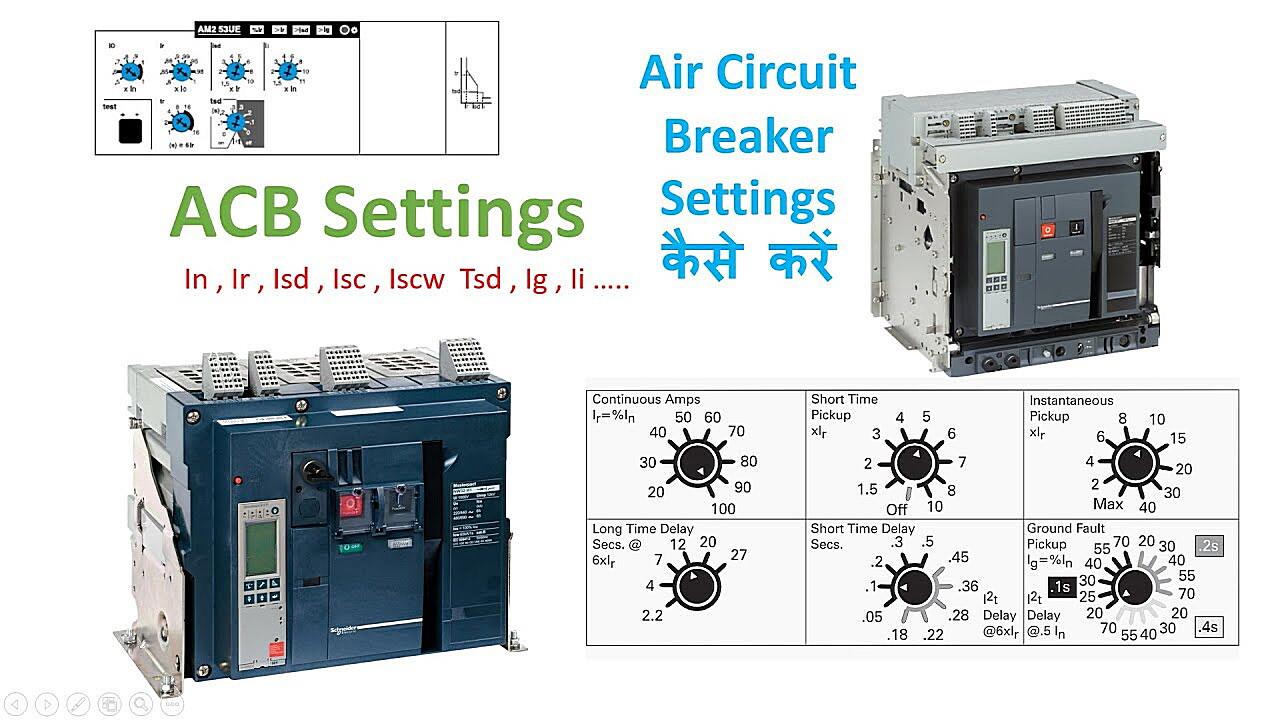

So, what makes one ACB able to handle a massive fault current while another might struggle? A bunch of factors come into play, and understanding them can help you make a more informed choice. First up, the voltage rating of the ACB is super important. An ACB designed for a higher voltage system will generally have a higher breaking capacity, as it needs to withstand the increased electrical stress during a fault.

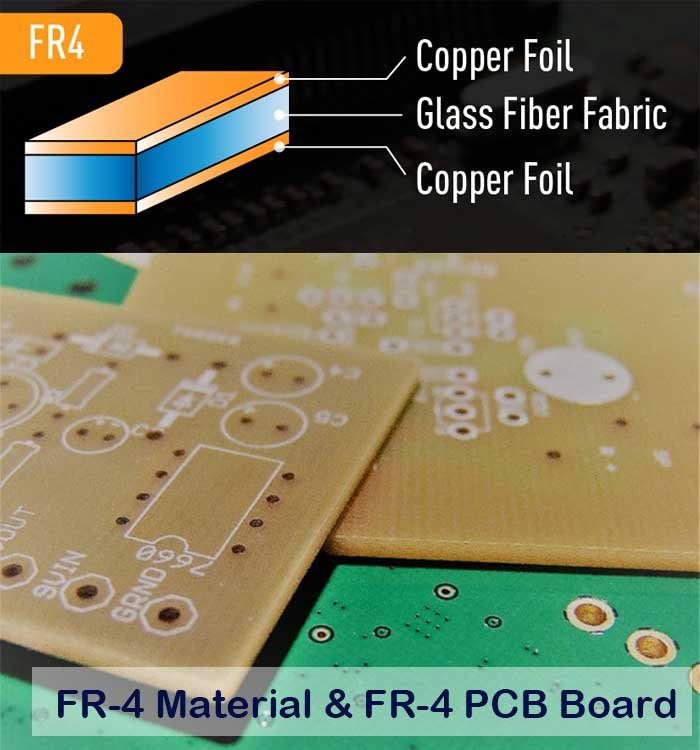

The internal design of the ACB also plays a crucial role. Things like the type of arc extinguishing medium (air, vacuum, SF6), the design of the contacts, and the speed of the operating mechanism all contribute to its breaking capacity. For instance, an ACB with a sophisticated arc chute design will be better at extinguishing the arc that forms when the contacts open, allowing it to interrupt higher fault currents. The materials used in the ACB’s construction also matter. High-quality materials that can withstand high temperatures and electrical stress are essential for ensuring reliable operation during fault conditions.

The interrupting time, which is the time it takes for the ACB to open its contacts and interrupt the fault current, is another critical factor. A faster interrupting time reduces the amount of energy dissipated during the fault, which in turn reduces the stress on the ACB and improves its breaking capacity. Factors like ambient temperature, altitude, and even the presence of harmonic currents can affect the ACB’s performance. Higher temperatures can reduce the ACB’s breaking capacity, while higher altitudes can affect the insulation strength. Harmonic currents can also increase the stress on the ACB and reduce its lifespan.

Finally, keep in mind that the breaking capacity is not a static value. It can degrade over time due to factors like wear and tear, contamination, and exposure to harsh environments. Regular maintenance and testing are essential to ensure that the ACB maintains its rated breaking capacity throughout its service life. Think of it like a car you need to get it serviced regularly to keep it running smoothly and safely.

Why Accurate Calculation Matters

4. The Consequences of Getting It Wrong

Imagine this: a hospital relying on life-support systems experiences a sudden power surge due to a fault. If the ACB protecting that circuit has an inadequate breaking capacity, the consequences could be dire. The breaker might fail to trip, leading to a complete power outage. This could cause critical medical equipment to shut down, potentially endangering patients’ lives. This is a stark reminder of why accurate calculation and selection of ACBs are essential, especially in critical applications.

Beyond safety, there are significant financial implications. An improperly sized ACB can lead to equipment damage, production downtime, and costly repairs. If a breaker fails to interrupt a fault current, the resulting damage can extend to other components in the electrical system, leading to a domino effect of failures. This can result in lengthy shutdowns, lost productivity, and significant financial losses. Think of it as a small investment in accurate calculation and proper ACB selection that can save you a fortune in the long run.

Proper selection isn’t just about avoiding disaster; it’s also about ensuring the longevity and reliability of your electrical system. An ACB that’s operating close to its breaking capacity will experience more stress and wear and tear, leading to a shorter lifespan. By choosing a breaker with an adequate margin of safety, you can reduce the stress on the system and extend its service life. This results in lower maintenance costs, reduced downtime, and a more reliable electrical system overall.

Finally, consider the legal and regulatory implications. In many jurisdictions, electrical installations are subject to strict regulations and codes that require proper overcurrent protection. Failure to comply with these regulations can result in fines, penalties, and even legal action. Accurate calculation and selection of ACBs are essential for ensuring compliance and avoiding costly legal issues. It’s not just about doing things right; it’s about doing things by the book.

FAQs

5. Clearing Up the Confusion

Let’s tackle some frequently asked questions to further clarify the world of ACB breaking capacity.

Q: What’s the difference between Icu and Ics?

A: Icu (ultimate breaking capacity) is the maximum fault current an ACB can interrupt once without damage. Ics (service breaking capacity) is the fault current it can interrupt multiple times and still function normally. Think of Icu as a one-time burst of power, while Ics is its sustainable performance level.

Q: How often should ACBs be tested?

A: It depends on the application and environment, but generally, ACBs should be inspected and tested annually. This ensures they’re operating correctly and haven’t degraded below their rated breaking capacity. Regular testing is like a health checkup for your electrical system.

Q: Can I use an ACB with a lower breaking capacity than the calculated fault current if I install a fuse upstream?

A: Generally, no. While a fuse might interrupt the fault current, the ACB still needs to be able to safely open its contacts and isolate the fault. Relying solely on a fuse might not provide adequate protection and could violate safety regulations. It is best to use the fuse as the first stage protection, and ACB as a second back-up protection.