You May Also Like :

The VFD and the Motor

1. Understanding the Relationship

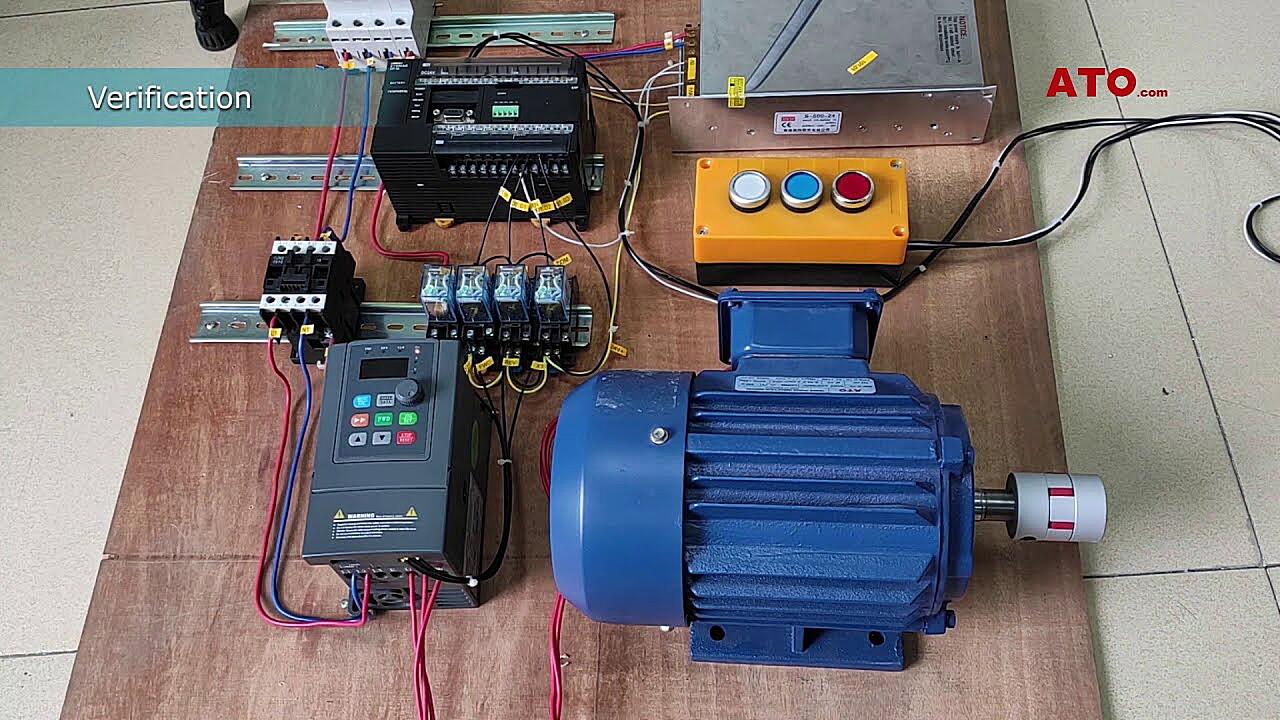

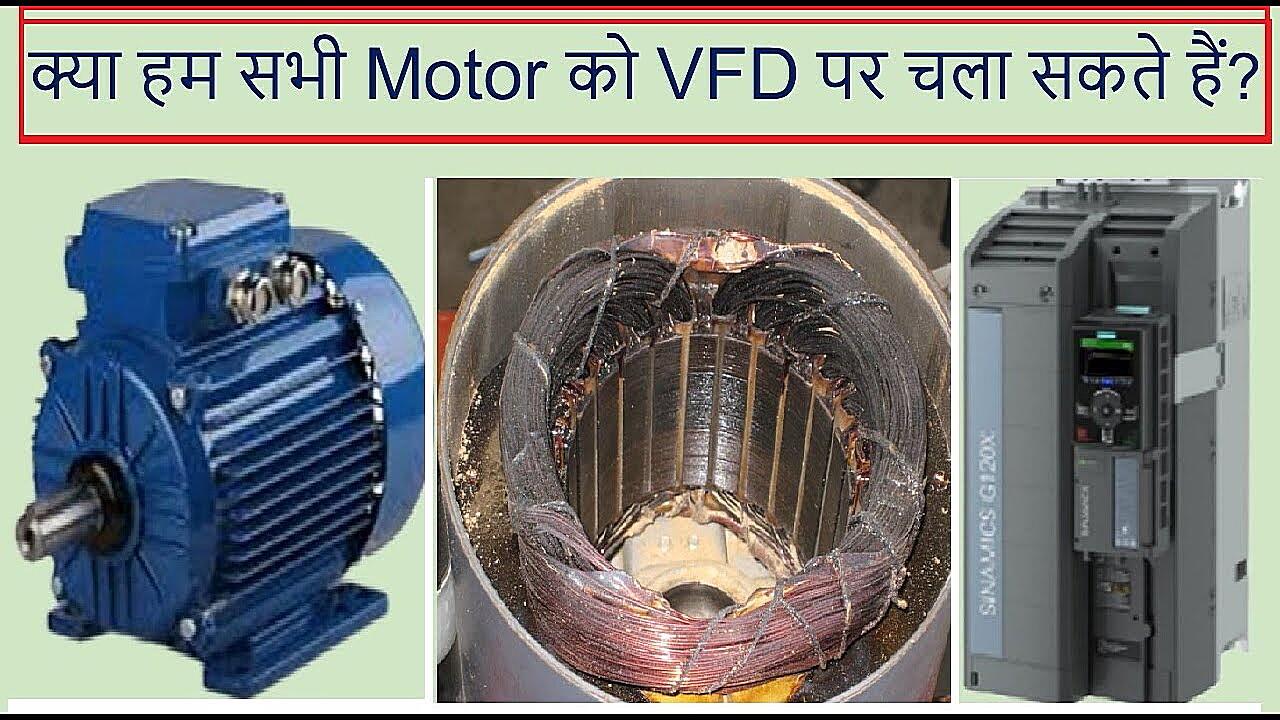

Variable Frequency Drives (VFDs) and motors, they’re a common pair in the industrial world, like peanut butter and jelly—usually. But sometimes, that harmony can go sour. The question swirling around is this: Can a VFD destroy a motor? The simple answer is, unfortunately, yes. But, before you start unplugging every VFD in sight, let’s explore why and how this happens, and what you can do to prevent it. Think of it like this: your motor is a marathon runner, and your VFD is the coach. A good coach prepares the runner well, but a bad one? Well, the runner might not finish the race in one piece.

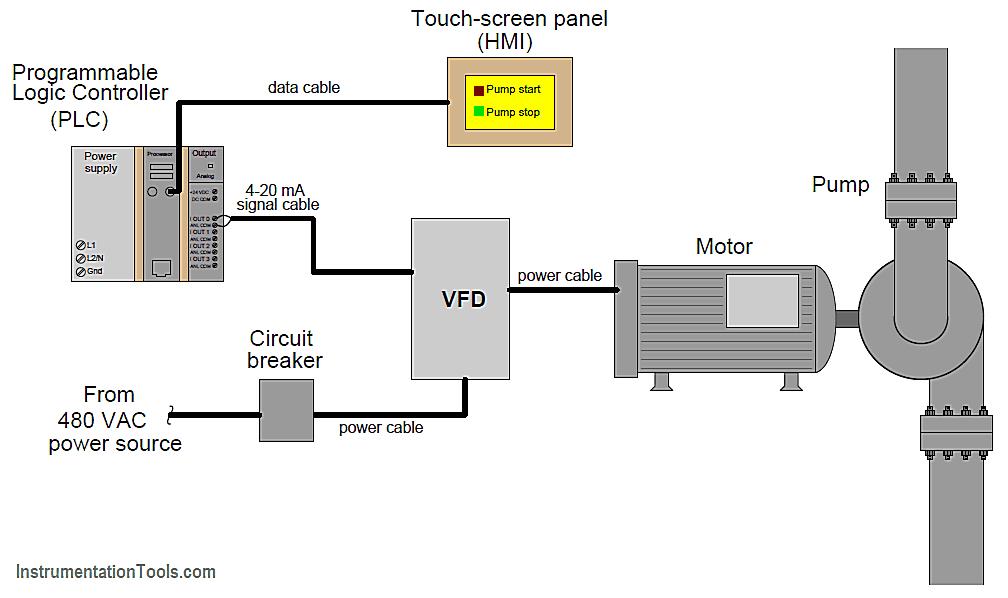

At their core, VFDs are designed to control the speed of AC induction motors by varying the frequency and voltage supplied to the motor. This allows for precise control and energy savings. When operating correctly, a VFD extends motor lifespan and improves efficiency. However, when things go wrong, those same capabilities can be the source of problems, leading to premature motor failure. We’re not talking “lightbulb goes out” failure, either. We’re talking about the kind of failure that involves smoke, strange smells, and an unplanned trip to the repair shop.

So, why does this happen? Several factors can contribute to a VFD turning from helpful partner to motor menace. It all boils down to understanding how VFDs work and what the motor expects. It’s not just about setting a speed and hitting “go.” There’s a bit more nuance involved. Improper settings, reflected waves, bearing currents, and overheating are all potential culprits.

It’s like baking a cake. You can’t just throw all the ingredients in at once and hope for the best. You need the right recipe, the right oven temperature, and a little bit of skill to get it right. Similarly, setting up a VFD requires understanding the motor’s specifications, the application requirements, and a good dose of technical know-how.

The Usual Suspects

2. Digging into the Details

Now, let’s get down to the nitty-gritty, but let’s not call it that. What are the specific reasons a VFD can wreak havoc on a motor? Here are some of the main culprits:

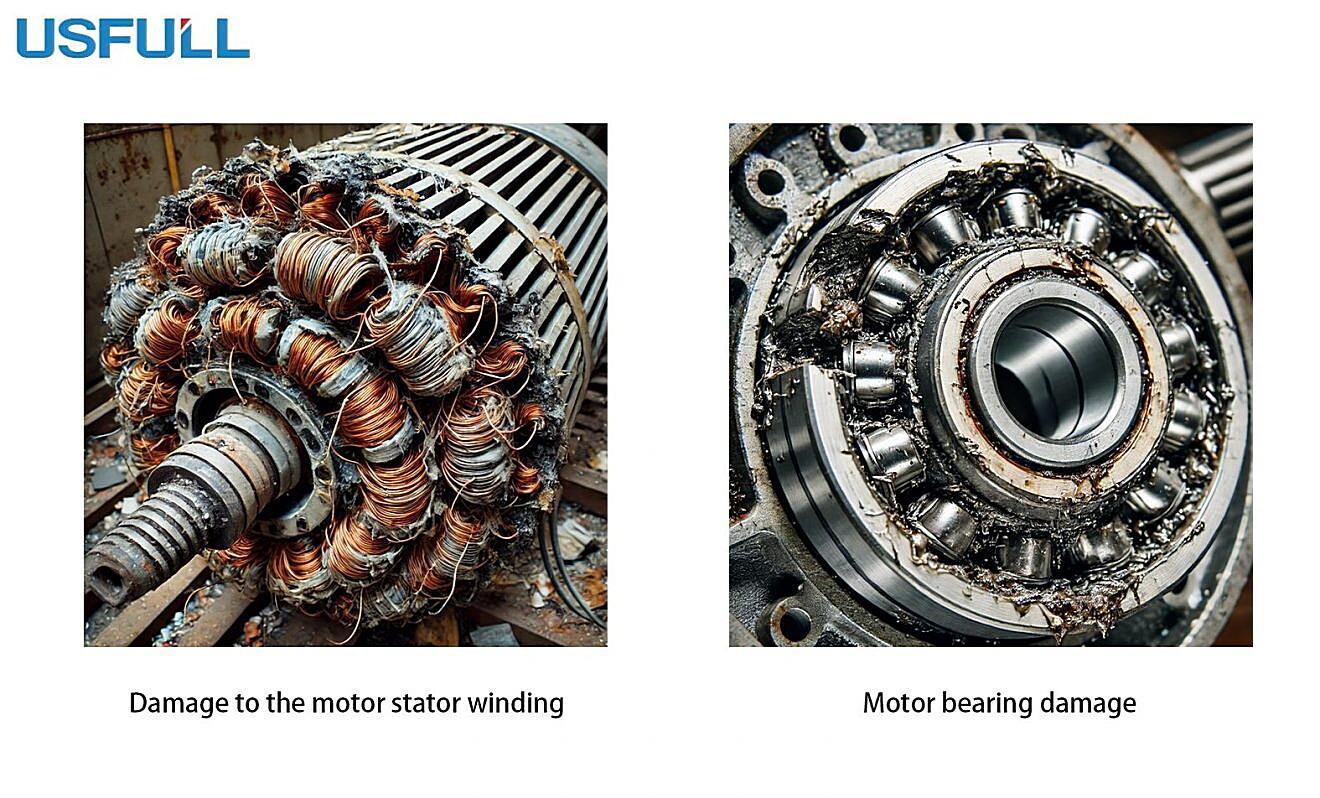

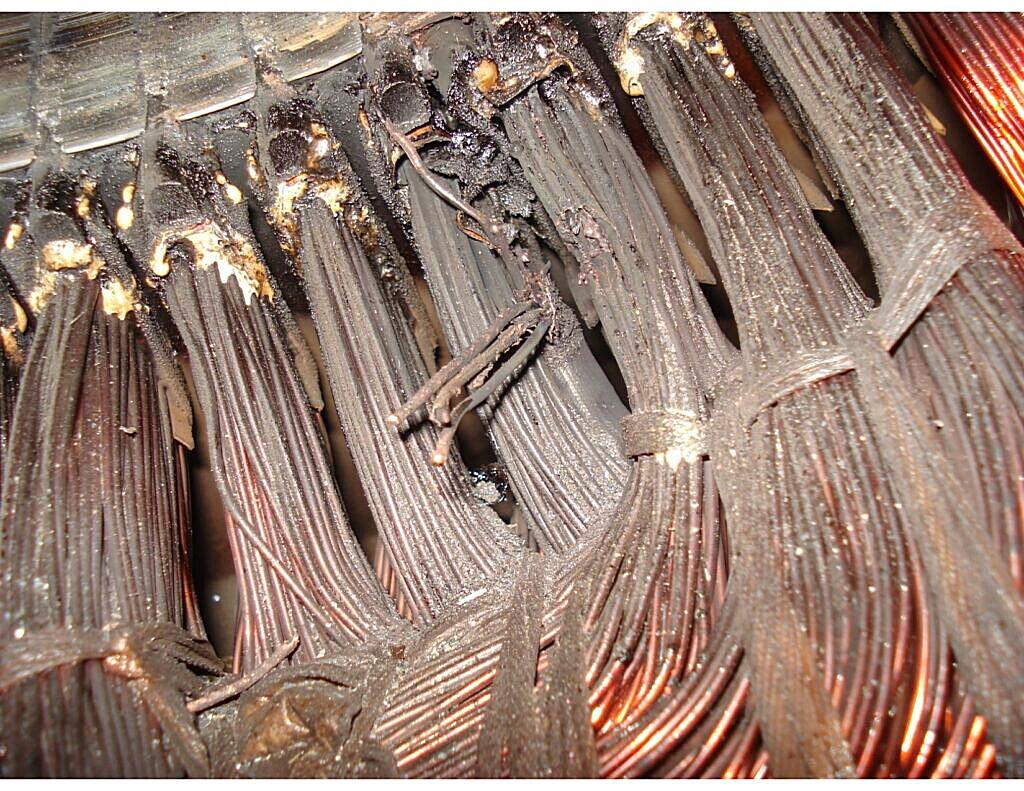

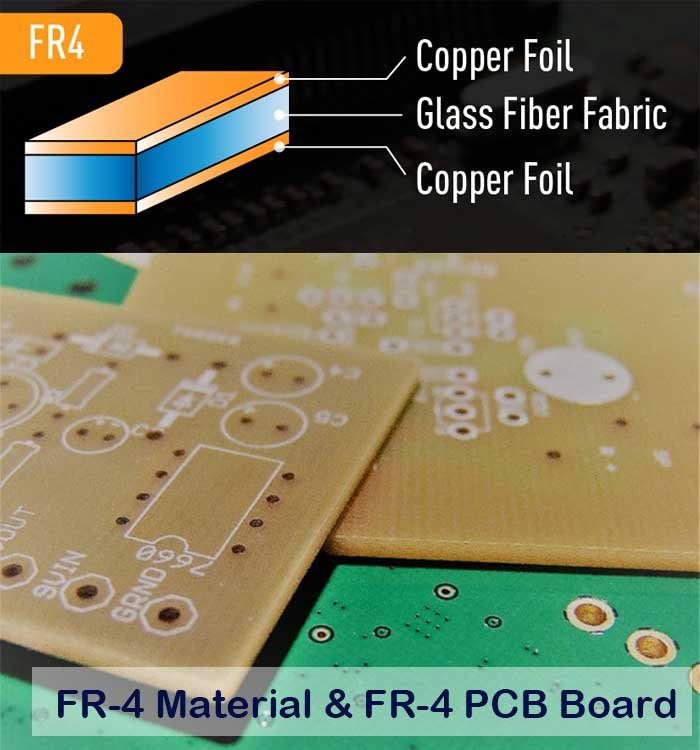

1. Reflected Waves: One of the biggest offenders is the issue of reflected waves. VFDs produce high-frequency pulses, and these pulses can reflect back down the motor cable, creating voltage spikes that exceed the motor’s insulation rating. This is like repeatedly hitting a wall with a hammer—eventually, the wall will crack. These voltage spikes cause insulation breakdown, leading to short circuits and motor failure.

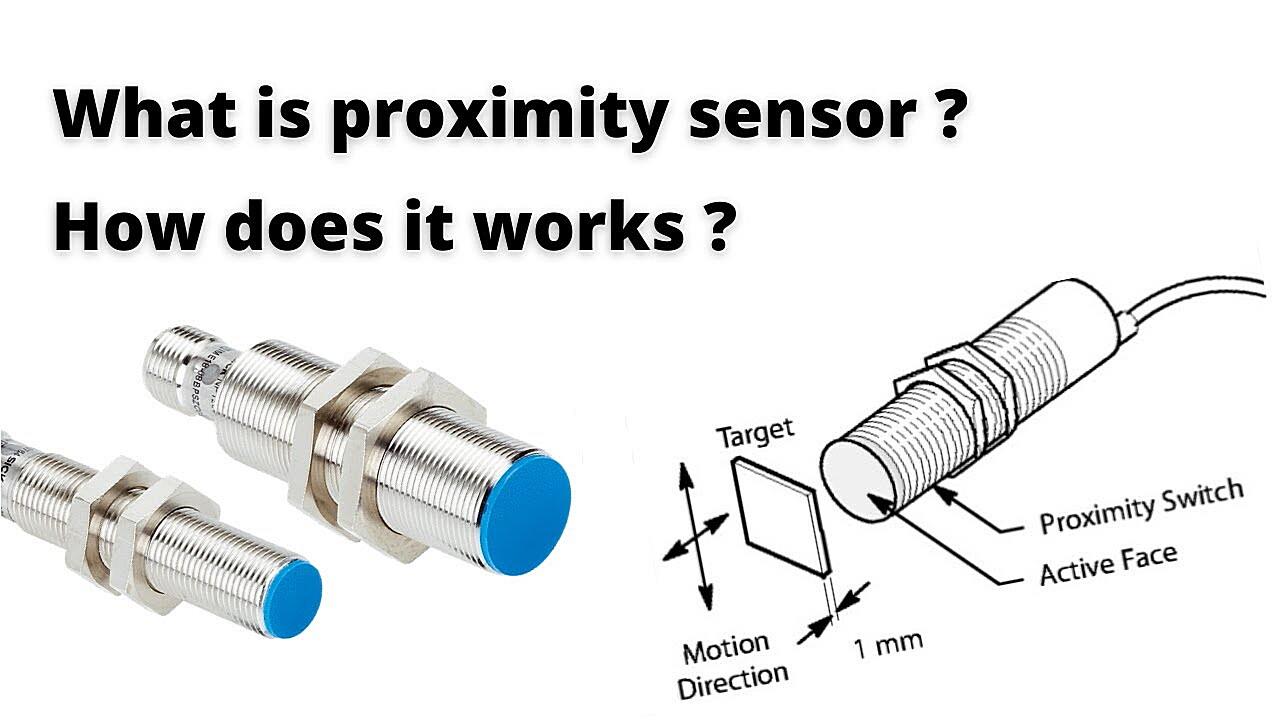

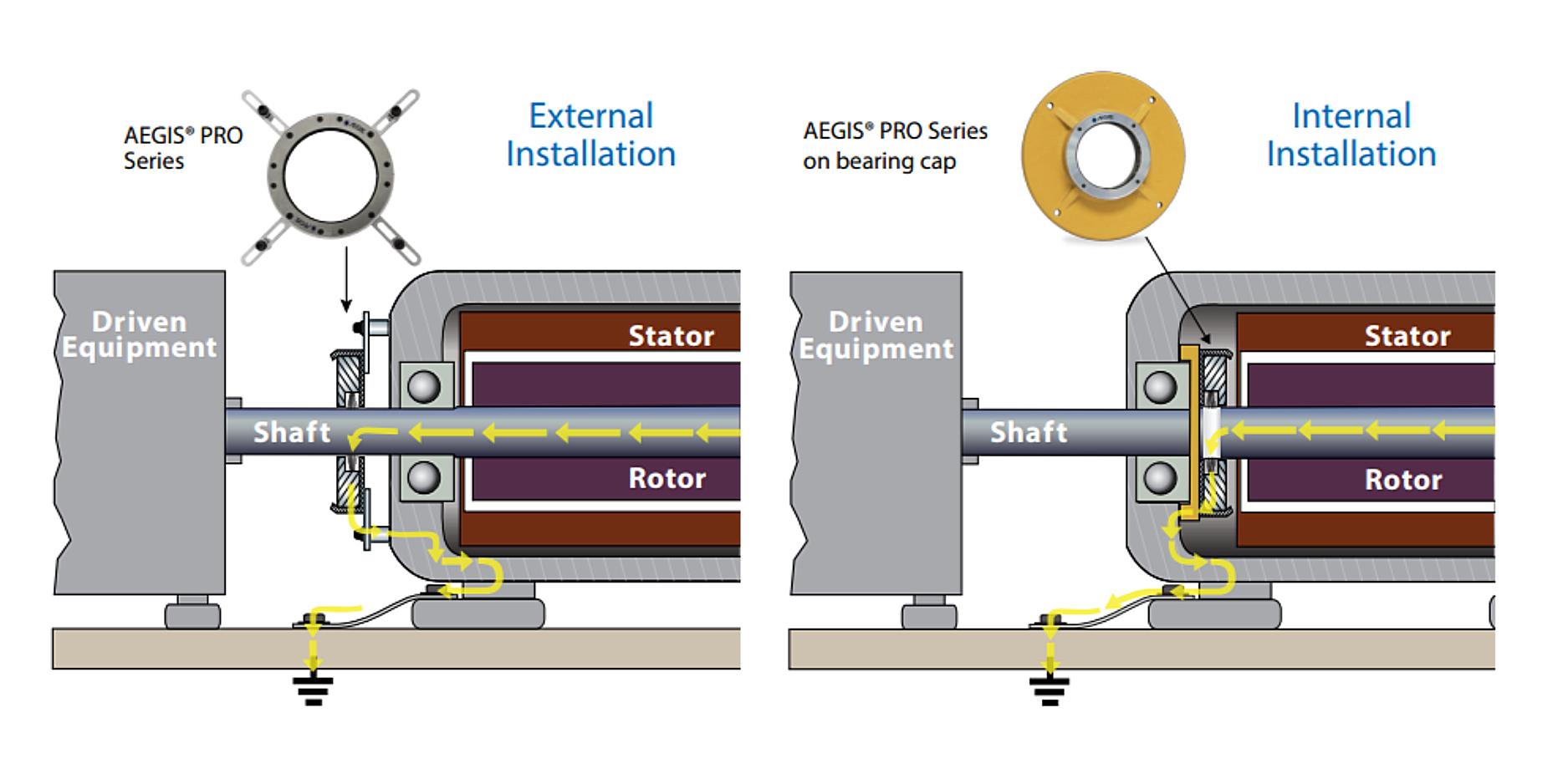

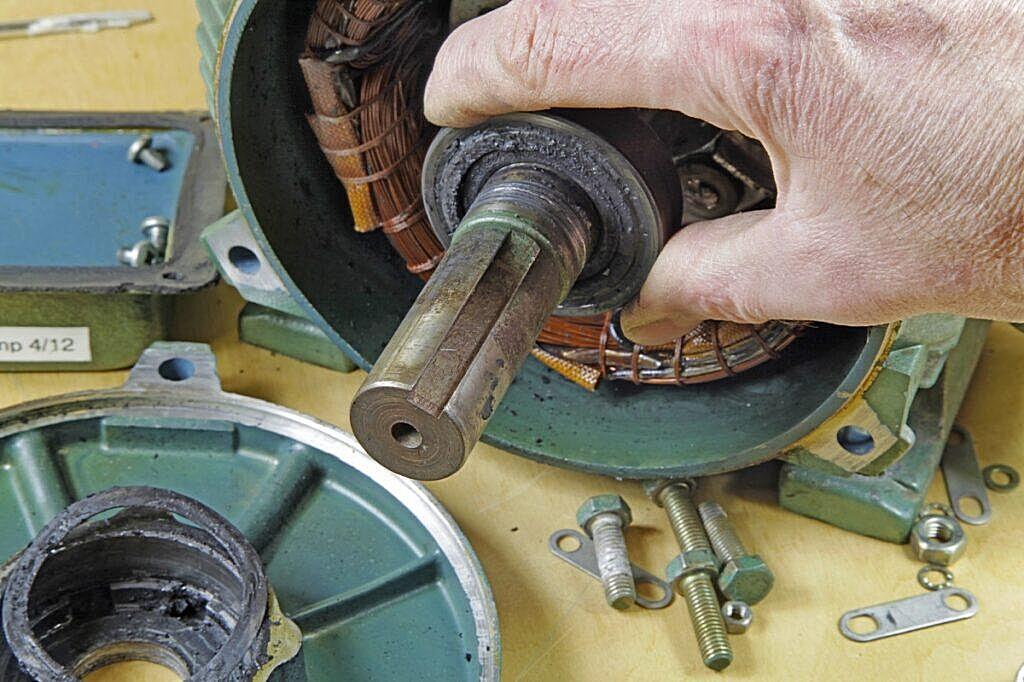

2. Bearing Currents: VFDs can induce currents in the motor shaft, which then discharge through the bearings. This electrical discharge can erode the bearing surfaces, causing premature bearing failure. Imagine tiny lightning bolts zapping through the bearings. Not good for longevity!

3. Overheating: Operating a motor at low speeds for extended periods can reduce the effectiveness of the motor’s cooling fan. This leads to overheating, which degrades the motor’s insulation and shortens its lifespan. It’s like trying to run a car engine at idle for hours—it’s not designed for that kind of sustained low-speed operation.

4. Incorrect Parameter Settings: If the VFD parameters aren’t properly configured for the motor, it can cause all sorts of problems. Incorrect voltage, frequency, or acceleration/deceleration rates can stress the motor beyond its design limits. Think of it as trying to fit a square peg into a round hole—it’s going to cause damage.

Protecting Your Motor

3. Strategies for Longevity

Okay, so we know the bad news. But what can you do to protect your motor from the perils of VFD-induced damage? Fortunately, there are several steps you can take:

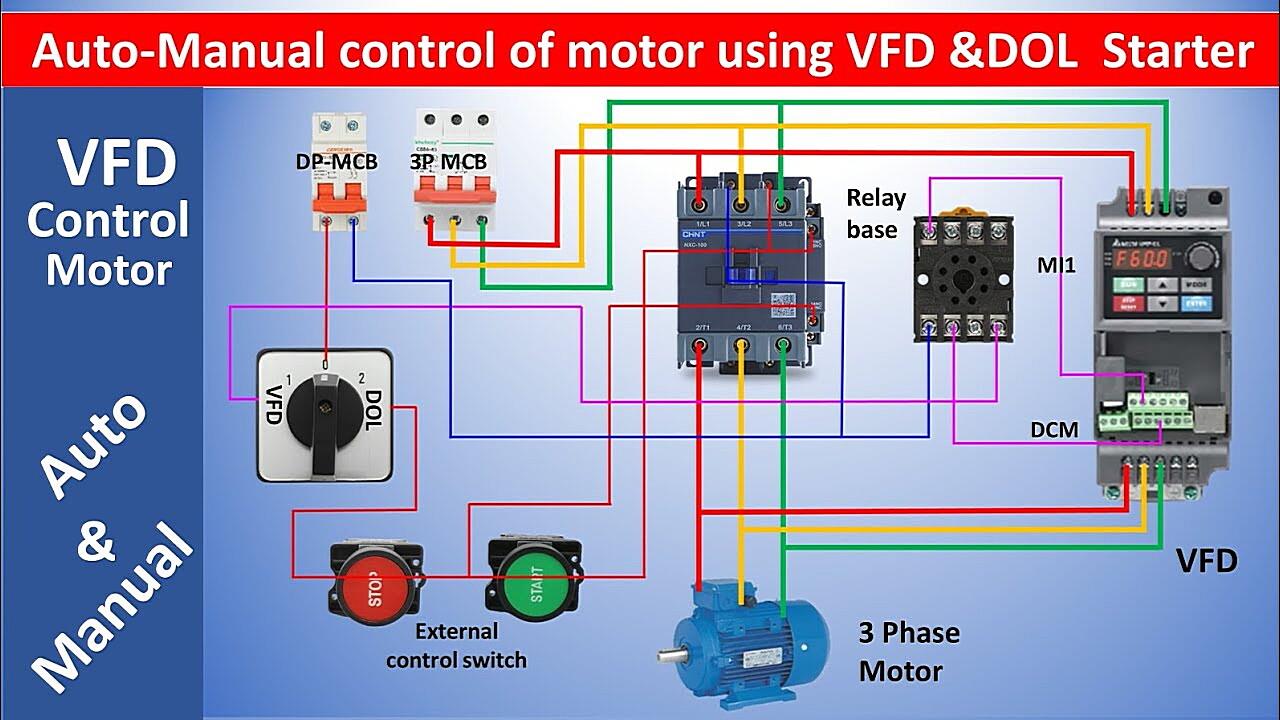

1. Use Motor Cables Designed for VFDs: Standard power cables aren’t designed to handle the high-frequency pulses produced by VFDs. VFD-rated cables have better shielding and insulation to minimize reflected waves and reduce electromagnetic interference. It’s like wearing the right protective gear for a dangerous sport.

2. Install Output Line Reactors or Filters: These devices help to smooth out the voltage pulses from the VFD, reducing the severity of reflected waves and mitigating voltage spikes at the motor terminals. Think of them as shock absorbers for your electrical system.

3. Grounding, Grounding, Grounding: Proper grounding is absolutely crucial. Ensure that the VFD, motor, and associated equipment are properly grounded to provide a low-impedance path for fault currents. This helps to minimize bearing currents and reduce the risk of electrical shock. Consider this the foundation of a safe electrical system.

4. Use Insulated Bearings or Shaft Grounding Rings: These solutions help to prevent bearing currents from causing damage. Insulated bearings block the flow of current through the bearings, while shaft grounding rings provide a path for the current to bypass the bearings entirely. It’s like building a detour around a construction zone.

5. Careful Parameter Configuration: Make sure that the VFD parameters are correctly configured for the specific motor being used. This includes voltage, frequency, current limits, and acceleration/deceleration rates. Refer to the motor’s nameplate data and the VFD’s documentation for guidance. It’s like following the recipe to the letter.

Motor Selection and VFD Compatibility

4. Choosing the Right Match

The marriage of a motor and a VFD begins with selecting the right partners. Not all motors are created equal, and some are better suited for VFD operation than others. When choosing a motor for use with a VFD, consider these points:

1. Inverter-Duty Motors: These motors are specifically designed to withstand the stresses imposed by VFDs. They have enhanced insulation, improved cooling, and features to mitigate bearing currents. Think of them as the athletes of the motor world, specifically trained for the VFD marathon.

2. Motor Insulation Rating: Ensure that the motor’s insulation rating is adequate for the voltage spikes produced by the VFD. A higher insulation rating provides greater protection against insulation breakdown. It’s like having a stronger shield to deflect the blows.

3. Motor Cooling: If the motor will be operated at low speeds for extended periods, consider using a motor with a separate forced-air cooling fan. This ensures adequate cooling even at low speeds. It’s like having an extra fan on a hot day.

4. Consider Motor Size: While it may seem counterintuitive, sometimes oversizing the motor slightly can increase its lifespan when paired with a VFD. The slightly larger motor won’t have to work as hard, thereby reducing heat and wear. Think of it as driving a truck with a light load — less stress on the engine.

Maintenance and Monitoring

5. The Vigilant Approach

Even with the best preventative measures in place, regular maintenance and monitoring are essential for ensuring the long-term health of your motor. Here are some key maintenance and monitoring practices:

1. Regular Inspections: Periodically inspect the motor, VFD, and associated wiring for signs of damage, overheating, or loose connections. Look for discoloration, unusual noises, or vibrations. It’s like giving your car a regular checkup.

2. Bearing Lubrication: Ensure that the motor bearings are properly lubricated. Follow the manufacturer’s recommendations for lubrication intervals and types of lubricant. This helps to prevent bearing failure. Think of it as keeping the gears well-oiled.

3. Temperature Monitoring: Monitor the motor’s operating temperature. Overheating is a sign of potential problems. Use a thermal imaging camera or temperature sensors to track the motor’s temperature over time. Early detection is key.

4. Vibration Analysis: Perform regular vibration analysis to detect signs of bearing wear or other mechanical issues. Vibration analysis can identify problems before they lead to catastrophic failure. It’s like listening to the engine for unusual sounds.

5. Record Keeping: Maintain detailed records of motor maintenance, repairs, and operating conditions. This helps to track trends and identify potential problems early on. It’s like keeping a medical history for your motor.

FAQ

6. Your Questions Answered

Here are some frequently asked questions about the relationship between VFDs and motors:

Q: Can I use any motor with a VFD?

A: While technically you can connect almost any AC motor to a VFD, it’s generally not recommended. Standard motors are not designed to withstand the voltage stresses and bearing currents produced by VFDs. Inverter-duty motors are specifically designed for VFD operation.

Q: What happens if I don’t use VFD-rated cable?

A: Using standard power cable can lead to reflected waves, voltage spikes, and electromagnetic interference, all of which can damage the motor and other equipment. VFD-rated cable has better shielding and insulation to mitigate these problems.

Q: How often should I inspect my motor and VFD?

A: The frequency of inspections depends on the application and operating conditions. However, a good rule of thumb is to perform a visual inspection at least monthly and a more thorough inspection quarterly. Critical applications may require more frequent inspections.

Q: What is an “inverter-duty” motor?

A: An inverter-duty motor is specifically designed to be paired with a VFD. They feature increased insulation, better cooling, and often have features like insulated bearings or shaft grounding rings to combat bearing currents. They are built tougher to handle the specific challenges that VFD operation presents.